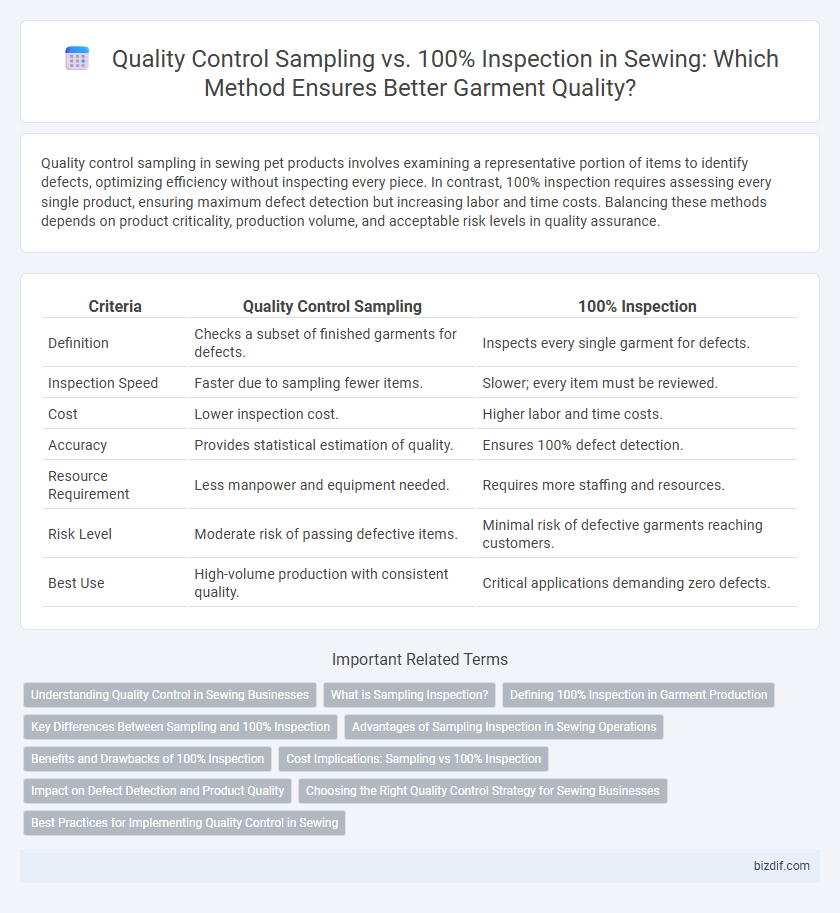

Quality control sampling in sewing pet products involves examining a representative portion of items to identify defects, optimizing efficiency without inspecting every piece. In contrast, 100% inspection requires assessing every single product, ensuring maximum defect detection but increasing labor and time costs. Balancing these methods depends on product criticality, production volume, and acceptable risk levels in quality assurance.

Table of Comparison

| Criteria | Quality Control Sampling | 100% Inspection |

|---|---|---|

| Definition | Checks a subset of finished garments for defects. | Inspects every single garment for defects. |

| Inspection Speed | Faster due to sampling fewer items. | Slower; every item must be reviewed. |

| Cost | Lower inspection cost. | Higher labor and time costs. |

| Accuracy | Provides statistical estimation of quality. | Ensures 100% defect detection. |

| Resource Requirement | Less manpower and equipment needed. | Requires more staffing and resources. |

| Risk Level | Moderate risk of passing defective items. | Minimal risk of defective garments reaching customers. |

| Best Use | High-volume production with consistent quality. | Critical applications demanding zero defects. |

Understanding Quality Control in Sewing Businesses

Quality control sampling in sewing businesses involves inspecting a representative subset of garments to identify defects and ensure overall product quality, optimizing resource use and reducing inspection time. In contrast, 100% inspection requires examining every garment, providing thorough defect detection but significantly increasing labor and operational costs. Choosing the appropriate method depends on production volume, defect rates, and quality standards, impacting customer satisfaction and brand reputation.

What is Sampling Inspection?

Sampling inspection in sewing involves evaluating a select portion of garments from a production lot to determine the overall quality, rather than examining every item. This method utilizes statistically derived sample sizes to detect defects and ensure compliance with quality standards efficiently. Sampling inspection balances thoroughness and resource management, making it a practical alternative to 100% inspection in large-scale garment manufacturing.

Defining 100% Inspection in Garment Production

100% inspection in garment production entails examining every individual item to identify defects, ensuring that no faulty pieces reach the customer. This method guarantees the highest level of quality assurance by thoroughly checking seams, fabric integrity, and finishing details. Despite its resource-intensive nature, 100% inspection minimizes returns and enhances brand reputation by maintaining consistent product standards.

Key Differences Between Sampling and 100% Inspection

Quality control sampling in sewing involves inspecting a representative subset of garments, enabling faster assessments and reduced labor costs while maintaining acceptable quality levels. In contrast, 100% inspection requires examining every single item, ensuring near-perfect defect detection but increasing time and resource consumption. Sampling balances efficiency and risk, whereas 100% inspection prioritizes thoroughness and maximum quality assurance.

Advantages of Sampling Inspection in Sewing Operations

Sampling inspection in sewing operations significantly reduces labor costs and inspection time compared to 100% inspection, enabling faster production turnaround. It allows continuous workflow by identifying defects early without halting the entire sewing line, maintaining operational efficiency. Statistical sampling methods also provide reliable quality assurance while minimizing resource expenditure and preventing inspection fatigue among quality control personnel.

Benefits and Drawbacks of 100% Inspection

100% inspection in sewing ensures every garment is checked for defects, leading to higher product quality and customer satisfaction. However, this method significantly increases labor costs and inspection time, making it less efficient for large production volumes. Despite thorough defect detection, human error and fatigue may still affect the accuracy and consistency of 100% inspections.

Cost Implications: Sampling vs 100% Inspection

Quality control sampling in sewing significantly reduces labor and inspection costs compared to 100% inspection by evaluating a representative subset of garments rather than every piece produced. While 100% inspection ensures maximum defect detection, it incurs higher operational expenses, including increased workforce hours and slower production throughput. Implementing sampling programs balances defect risk and cost efficiency, optimizing resource allocation without compromising product quality standards.

Impact on Defect Detection and Product Quality

Quality control sampling in sewing allows for efficient defect detection by testing a representative subset of garments, balancing inspection time with maintaining a consistent product quality. In contrast, 100% inspection ensures every item is checked, significantly reducing the risk of defective products reaching customers but increasing labor costs and inspection time. Implementing a strategic sampling plan optimized with statistical methods can improve defect detection rates while preserving production efficiency in garment manufacturing.

Choosing the Right Quality Control Strategy for Sewing Businesses

Quality control sampling in sewing businesses allows for efficient detection of defects by inspecting a representative subset of garments, optimizing resources and reducing inspection time while maintaining accuracy. In contrast, 100% inspection guarantees that every item is checked, minimizing the risk of defective products but significantly increasing labor costs and production time. Selecting the appropriate strategy depends on factors such as order volume, defect tolerance, production complexity, and customer requirements to balance quality assurance and operational efficiency.

Best Practices for Implementing Quality Control in Sewing

Quality control sampling in sewing balances efficiency and defect detection by inspecting a representative portion of garments, reducing labor costs while maintaining product standards. Implementing 100% inspection ensures each item meets quality criteria but demands significant time and resources, suitable for high-risk or critical components. Best practices include defining clear acceptance criteria, training inspectors thoroughly, and using statistical methods to determine optimal sample sizes that align with production goals and defect tolerance.

Quality Control Sampling vs 100% Inspection Infographic

bizdif.com

bizdif.com