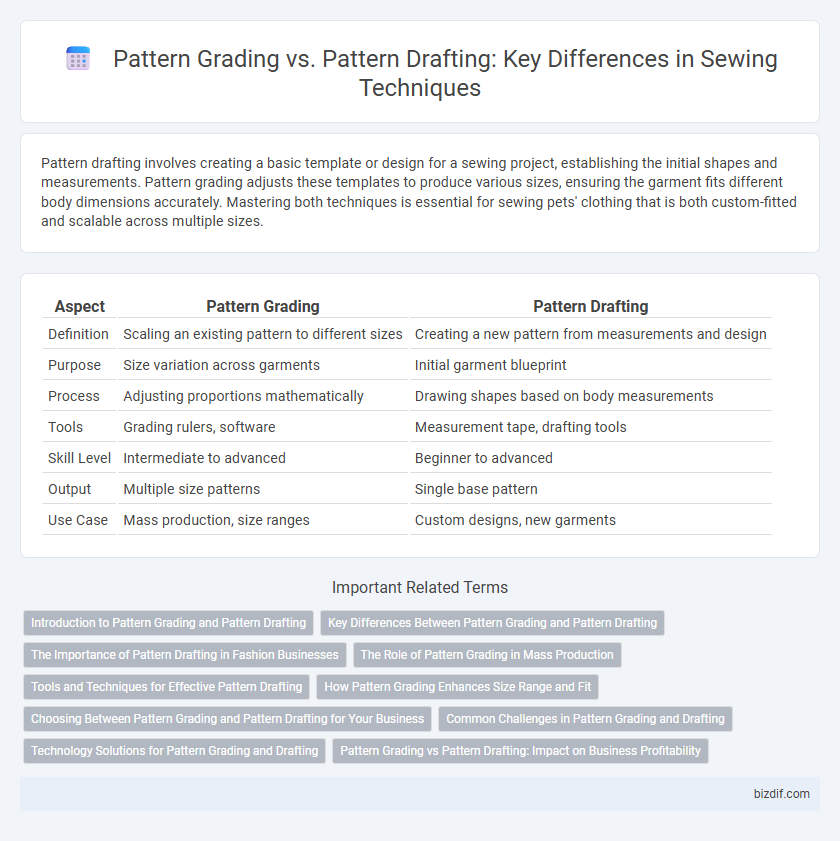

Pattern drafting involves creating a basic template or design for a sewing project, establishing the initial shapes and measurements. Pattern grading adjusts these templates to produce various sizes, ensuring the garment fits different body dimensions accurately. Mastering both techniques is essential for sewing pets' clothing that is both custom-fitted and scalable across multiple sizes.

Table of Comparison

| Aspect | Pattern Grading | Pattern Drafting |

|---|---|---|

| Definition | Scaling an existing pattern to different sizes | Creating a new pattern from measurements and design |

| Purpose | Size variation across garments | Initial garment blueprint |

| Process | Adjusting proportions mathematically | Drawing shapes based on body measurements |

| Tools | Grading rulers, software | Measurement tape, drafting tools |

| Skill Level | Intermediate to advanced | Beginner to advanced |

| Output | Multiple size patterns | Single base pattern |

| Use Case | Mass production, size ranges | Custom designs, new garments |

Introduction to Pattern Grading and Pattern Drafting

Pattern drafting involves creating original sewing templates based on precise body measurements, allowing for custom-fitted garment designs. Pattern grading is the systematic process of resizing a base pattern to create multiple sizes, maintaining the garment's proportions and style. Mastering pattern drafting and grading is essential for efficient garment production and achieving consistent fit across size ranges.

Key Differences Between Pattern Grading and Pattern Drafting

Pattern grading involves resizing an existing sewing pattern to create multiple sizes while maintaining proportions and fit, using precise measurement increments. Pattern drafting is the process of creating a new sewing pattern from scratch based on specific body measurements or design requirements, forming the foundation of garment construction. Key differences include grading's focus on size adaptation and drafting's emphasis on original pattern creation tailored to individual or design specifications.

The Importance of Pattern Drafting in Fashion Businesses

Pattern drafting is crucial in fashion businesses as it ensures precise garment fit and design customization, directly impacting product quality and customer satisfaction. Unlike pattern grading, which adjusts sizes from a base pattern, drafting creates original, detailed templates tailored for specific designs, allowing for innovation and brand uniqueness. Mastery in pattern drafting streamlines production processes and reduces sample errors, ultimately saving time and cost for fashion companies.

The Role of Pattern Grading in Mass Production

Pattern grading plays a crucial role in mass production by efficiently scaling a base garment pattern to multiple sizes, ensuring consistent fit across a wide range of body measurements. This process leverages precise measurements and grading increments to maintain design integrity and proportion, unlike pattern drafting which involves creating a pattern from scratch for an individual size. The accuracy of pattern grading directly impacts manufacturing speed, fabric utilization, and overall production cost in the apparel industry.

Tools and Techniques for Effective Pattern Drafting

Pattern drafting relies on precise tools such as rulers, French curves, and tracing wheels to create custom garment templates from scratch, ensuring accurate measurements and fit. In contrast, pattern grading uses specialized software or manual grading rulers to scale existing patterns up or down, maintaining proportions across sizes. Effective pattern drafting combines hand-sketching techniques with digital tools like CAD programs to enhance accuracy and streamline design modifications.

How Pattern Grading Enhances Size Range and Fit

Pattern grading increases size range by systematically scaling a base pattern to create accurate variations for different body measurements, ensuring consistent proportions across sizes. This method allows garment manufacturers to efficiently produce multiple sizes without compromising fit quality, addressing diverse customer body shapes. Enhanced precision in grading minimizes fit issues, leading to better-fitting clothing and improved customer satisfaction.

Choosing Between Pattern Grading and Pattern Drafting for Your Business

Pattern grading involves resizing an existing pattern to create multiple sizes, ensuring consistency and scalability in mass production. Pattern drafting requires creating a custom pattern from scratch based on specific measurements, allowing for unique and tailored designs. Businesses aiming for efficient size range expansion with standardized fit benefit from grading, while those prioritizing bespoke, one-of-a-kind garments should invest in drafting expertise.

Common Challenges in Pattern Grading and Drafting

Pattern grading often struggles with maintaining consistent fit across multiple sizes, leading to distortions in proportions and shape. Pattern drafting requires precise measurements and a strong understanding of garment construction, with challenges including accuracy in translating designs to flat patterns and ensuring proper seam allowances. Both processes demand advanced technical skills and attention to detail to avoid issues such as uneven garment fit and fabric wastage.

Technology Solutions for Pattern Grading and Drafting

Advanced technology solutions for pattern grading and drafting streamline garment production by utilizing CAD software that enhances precision and efficiency. Digital tools enable automatic size adjustments, reducing manual errors and accelerating the development cycle while maintaining design integrity. Integration of 3D modeling and AI-powered algorithms further optimizes fit customization and pattern accuracy across multiple sizing standards.

Pattern Grading vs Pattern Drafting: Impact on Business Profitability

Pattern grading adjusts an existing sewing pattern to create multiple sizes, streamlining production and reducing development costs, which boosts business profitability. Pattern drafting involves creating original patterns from scratch, offering bespoke designs but requiring more time and specialized skill, potentially increasing expenses. Efficient use of grading enhances scalability and faster market entry, while drafting supports customization and brand differentiation, impacting profit margins based on business model.

Pattern Grading vs Pattern Drafting Infographic

bizdif.com

bizdif.com