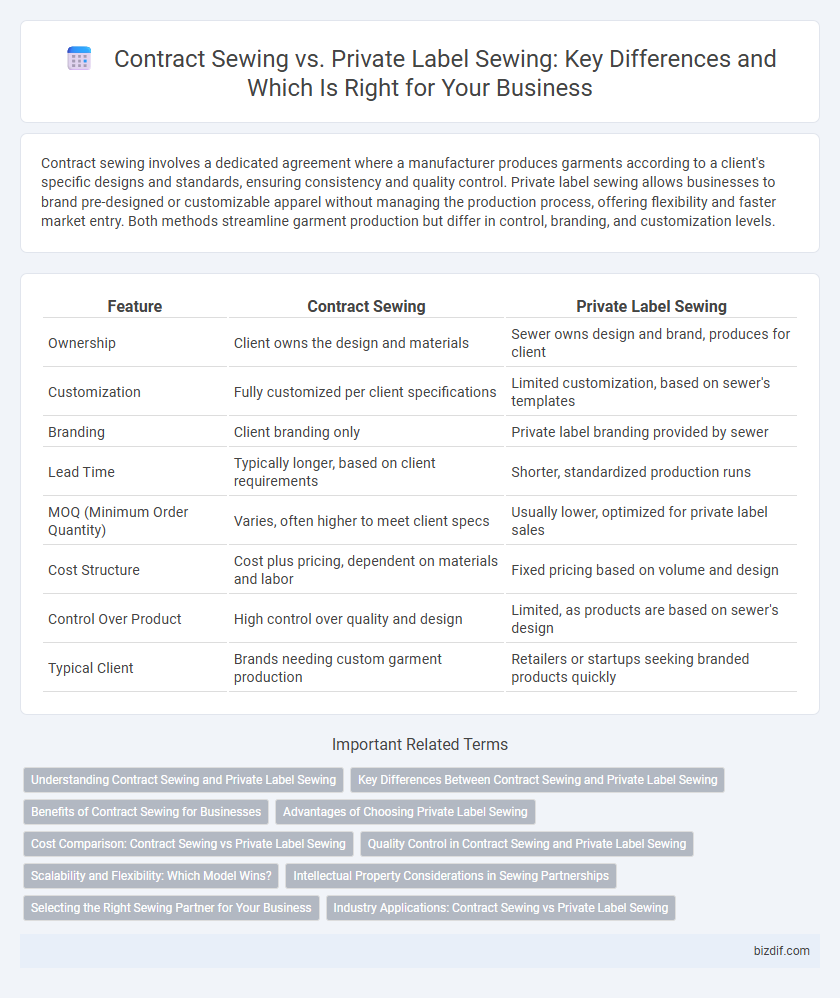

Contract sewing involves a dedicated agreement where a manufacturer produces garments according to a client's specific designs and standards, ensuring consistency and quality control. Private label sewing allows businesses to brand pre-designed or customizable apparel without managing the production process, offering flexibility and faster market entry. Both methods streamline garment production but differ in control, branding, and customization levels.

Table of Comparison

| Feature | Contract Sewing | Private Label Sewing |

|---|---|---|

| Ownership | Client owns the design and materials | Sewer owns design and brand, produces for client |

| Customization | Fully customized per client specifications | Limited customization, based on sewer's templates |

| Branding | Client branding only | Private label branding provided by sewer |

| Lead Time | Typically longer, based on client requirements | Shorter, standardized production runs |

| MOQ (Minimum Order Quantity) | Varies, often higher to meet client specs | Usually lower, optimized for private label sales |

| Cost Structure | Cost plus pricing, dependent on materials and labor | Fixed pricing based on volume and design |

| Control Over Product | High control over quality and design | Limited, as products are based on sewer's design |

| Typical Client | Brands needing custom garment production | Retailers or startups seeking branded products quickly |

Understanding Contract Sewing and Private Label Sewing

Contract sewing involves a business outsourcing garment production to a manufacturer who produces items based on the client's specifications and designs, often requiring strict compliance with quality and delivery standards. Private label sewing refers to manufacturers creating custom garments that retailers or brands sell under their own label, allowing businesses to offer unique products without managing production directly. Understanding these distinctions helps brands optimize supply chains, control costs, and maintain brand identity through tailored production strategies.

Key Differences Between Contract Sewing and Private Label Sewing

Contract sewing involves a manufacturer producing garments based on another company's designs and specifications, ensuring strict adherence to quality and production standards. Private label sewing allows brands to create customized apparel with their own labels, offering greater control over design, branding, and marketing strategies. The primary difference lies in ownership of the product design and brand identity, where contract sewing supports external brand requirements and private label sewing builds a unique brand presence.

Benefits of Contract Sewing for Businesses

Contract sewing offers businesses cost-effective production by leveraging specialized manufacturers with advanced equipment and skilled labor, reducing overhead and capital investment. It enables scalable manufacturing with consistent quality control, meeting large order demands efficiently while maintaining brand standards. Outsourcing sewing tasks enhances operational flexibility, allowing companies to focus on design, marketing, and sales without the complexities of in-house production management.

Advantages of Choosing Private Label Sewing

Private label sewing offers brands complete control over product design, quality standards, and branding, resulting in unique, market-tailored apparel that strengthens brand identity. This approach ensures faster turnaround times and more flexible production schedules compared to contract sewing, allowing businesses to respond quickly to market trends and consumer demands. Enhanced confidentiality and intellectual property protection through private label sewing also safeguard proprietary designs and innovations from competitors.

Cost Comparison: Contract Sewing vs Private Label Sewing

Contract sewing typically offers lower upfront costs due to bulk production and established manufacturing processes, making it cost-effective for larger orders. Private label sewing often involves higher initial expenses related to custom design, branding, and smaller production runs, but allows greater control over product uniqueness. Evaluating cost per unit, contract sewing benefits scale economies, while private label sewing incurs premium costs for exclusivity and customization.

Quality Control in Contract Sewing and Private Label Sewing

Contract sewing enforces rigorous quality control standards through detailed agreements specifying fabric selection, stitching techniques, and inspection processes to ensure consistent product quality aligned with client requirements. Private label sewing often involves integrated quality management systems where brands oversee every production phase, maintaining strict oversight to uphold their own label standards and consumer expectations. Both methods prioritize defect detection and correction, but contract sewing relies more heavily on supplier adherence to predetermined quality benchmarks, while private label sewing emphasizes brand-driven quality assurance protocols.

Scalability and Flexibility: Which Model Wins?

Contract sewing offers greater scalability by allowing businesses to handle large order volumes without investing in manufacturing infrastructure, while private label sewing provides more flexibility through customized control over designs and production timelines. Companies aiming for rapid growth often prefer contract sewing due to its capacity to quickly scale operations and reduce lead times. Private label sewing suits brands prioritizing unique product differentiation and personalized production processes, enhancing adaptability to market trends and consumer demands.

Intellectual Property Considerations in Sewing Partnerships

Contract sewing agreements typically grant manufacturers the rights to produce designs owned by the client, ensuring intellectual property (IP) remains with the brand owner, protecting their proprietary patterns and trademarks. Private label sewing involves producing garments under the manufacturer's brand, which may complicate IP rights due to shared design ownership or lack of clear agreements. Clear contractual terms specifying IP ownership, confidentiality, and usage rights are essential in sewing partnerships to prevent disputes and safeguard design innovations.

Selecting the Right Sewing Partner for Your Business

Choosing between contract sewing and private label sewing depends on your business goals, budget, and control preferences. Contract sewing offers flexibility by outsourcing production without branding responsibilities, ideal for startups or seasonal lines. Private label sewing provides complete branding control and unique product differentiation, benefiting established brands seeking to enhance market presence and customer loyalty.

Industry Applications: Contract Sewing vs Private Label Sewing

Contract sewing services cater to a wide range of industries such as apparel, automotive upholstery, and home textiles, providing specialized manufacturing expertise tailored to clients' product specifications. Private label sewing primarily targets fashion brands and retail companies seeking customized clothing lines with exclusive branding and design control. Both approaches emphasize quality craftsmanship but differ in production scale and brand ownership, impacting their suitability for various market applications.

Contract Sewing vs Private Label Sewing Infographic

bizdif.com

bizdif.com