Zigzag stitch offers greater flexibility and durability, making it ideal for sewing stretch fabrics and reinforcing seams on pet accessories like collars and harnesses. Straight stitch provides a clean, strong line perfect for basic seams and topstitching on pet clothing or soft toys. Choosing between zigzag and straight stitch depends on the fabric type and the specific strength and elasticity needs of your pet sewing project.

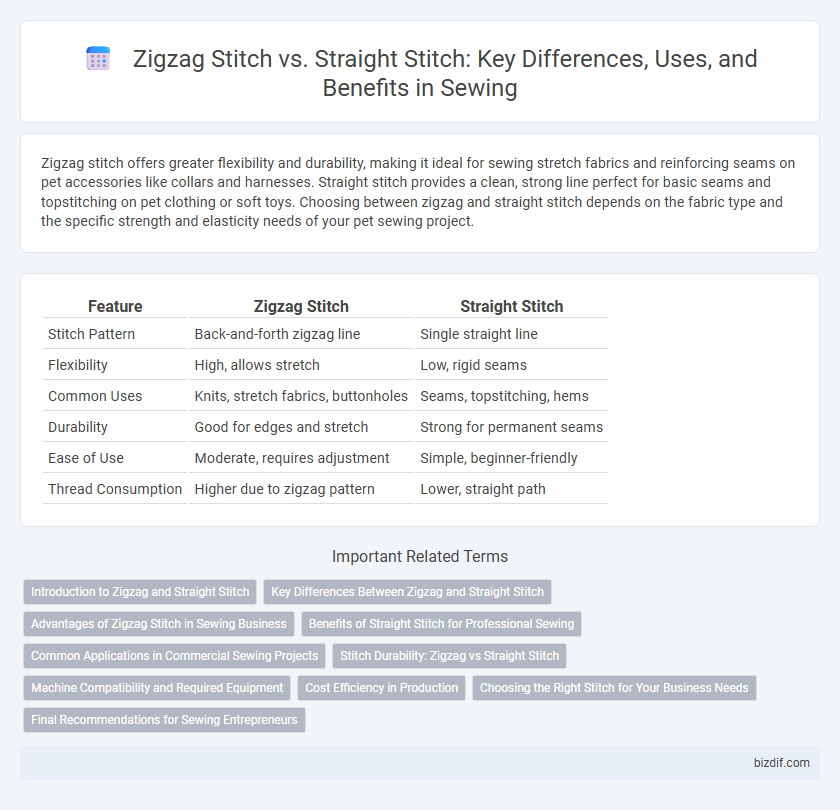

Table of Comparison

| Feature | Zigzag Stitch | Straight Stitch |

|---|---|---|

| Stitch Pattern | Back-and-forth zigzag line | Single straight line |

| Flexibility | High, allows stretch | Low, rigid seams |

| Common Uses | Knits, stretch fabrics, buttonholes | Seams, topstitching, hems |

| Durability | Good for edges and stretch | Strong for permanent seams |

| Ease of Use | Moderate, requires adjustment | Simple, beginner-friendly |

| Thread Consumption | Higher due to zigzag pattern | Lower, straight path |

Introduction to Zigzag and Straight Stitch

Zigzag stitch and straight stitch are fundamental sewing techniques essential for fabric construction and finishing. Straight stitch creates a strong, clean line used for basic seams, while zigzag stitch offers flexibility and stretch, making it ideal for preventing fabric fraying and sewing stretch materials. Understanding the applications and machine settings for each stitch enhances garment durability and professional-quality sewing results.

Key Differences Between Zigzag and Straight Stitch

Zigzag stitch features a side-to-side motion that allows for stretchy seams and edge finishing, making it ideal for knit fabrics and preventing fraying. Straight stitch produces a linear, strong seam best suited for woven fabrics and basic seams that require durability without stretch. The zigzag's wider stitch width contrasts with the straight stitch's narrow, consistent stitch line, providing versatility in fabric types and sewing functions.

Advantages of Zigzag Stitch in Sewing Business

Zigzag stitch offers superior flexibility and strength, making it ideal for finishing seams and preventing fabric fraying in diverse sewing projects. Its versatility allows businesses to handle elastic fabrics and decorative patterns effectively, expanding the range of marketable products. This stitch type enhances durability and aesthetic appeal, contributing to higher customer satisfaction and increased sales in the sewing industry.

Benefits of Straight Stitch for Professional Sewing

The straight stitch provides superior strength and durability, making it ideal for professional sewing projects that require clean, precise seams. Its simplicity allows for efficient machine operation, resulting in faster production times and consistent stitch quality. Additionally, straight stitches offer excellent fabric alignment and minimal distortion, ensuring high-quality garment construction.

Common Applications in Commercial Sewing Projects

Zigzag stitches are frequently used in commercial sewing projects for stretch fabrics, seam reinforcement, and edge finishing due to their flexibility and durability. Straight stitches provide precise, clean seams ideal for woven fabrics and topstitching applications that require strong, stable lines. Both stitch types are essential in manufacturing garments, upholstery, and accessories, balancing functionality and aesthetic quality in mass production.

Stitch Durability: Zigzag vs Straight Stitch

Zigzag stitch offers greater durability than a straight stitch due to its wider pattern that distributes tension more evenly across the fabric, reducing the risk of thread breakage. Straight stitches provide a clean, strong seam ideal for most fabrics but are more prone to unraveling under stress or stretch. For applications requiring stretch resistance or reinforcement, such as in knitwear or buttonholes, zigzag stitch is the preferred choice to enhance seam longevity.

Machine Compatibility and Required Equipment

Zigzag stitch and straight stitch machines both require compatible sewing machines with adjustable stitch settings, but zigzag stitching demands machines capable of lateral needle movement. Straight stitch machines, often used for basic sewing, typically feature a single needle position, whereas zigzag machines offer multiple stitch width options essential for stretch fabrics and decorative finishes. Additional equipment for zigzag stitches may include specialized presser feet to maintain fabric tension and precision during wider stitches.

Cost Efficiency in Production

Zigzag stitches offer greater cost efficiency in production by reducing fabric fraying, which minimizes material waste and lowers replacement costs. Straight stitches, while faster to sew, often require additional finishing processes that increase labor time and overall expenses. Manufacturers choosing zigzag stitching benefit from a balance of durability and reduced rework, optimizing production budgets.

Choosing the Right Stitch for Your Business Needs

Selecting the appropriate stitch type, such as zigzag stitch or straight stitch, depends on the intended fabric flexibility and garment durability required by your business. Zigzag stitches offer superior stretch and reinforcement, ideal for knit fabrics and preventing fraying, while straight stitches provide clean, strong seams suitable for woven fabrics and structured designs. Evaluating product function, material type, and production efficiency will guide the optimal choice to meet quality standards and customer satisfaction.

Final Recommendations for Sewing Entrepreneurs

Zigzag stitches offer greater flexibility and durability, making them ideal for stretchy fabrics and decorative finishes, while straight stitches provide strong, precise seams perfect for woven fabrics and basic construction. Sewing entrepreneurs should invest in machines that can easily switch between stitch types to accommodate diverse project needs and enhance product quality. Prioritizing stitch versatility supports efficient production workflows and expands creative possibilities, ultimately boosting customer satisfaction and business growth.

Zigzag Stitch vs Straight Stitch Infographic

bizdif.com

bizdif.com