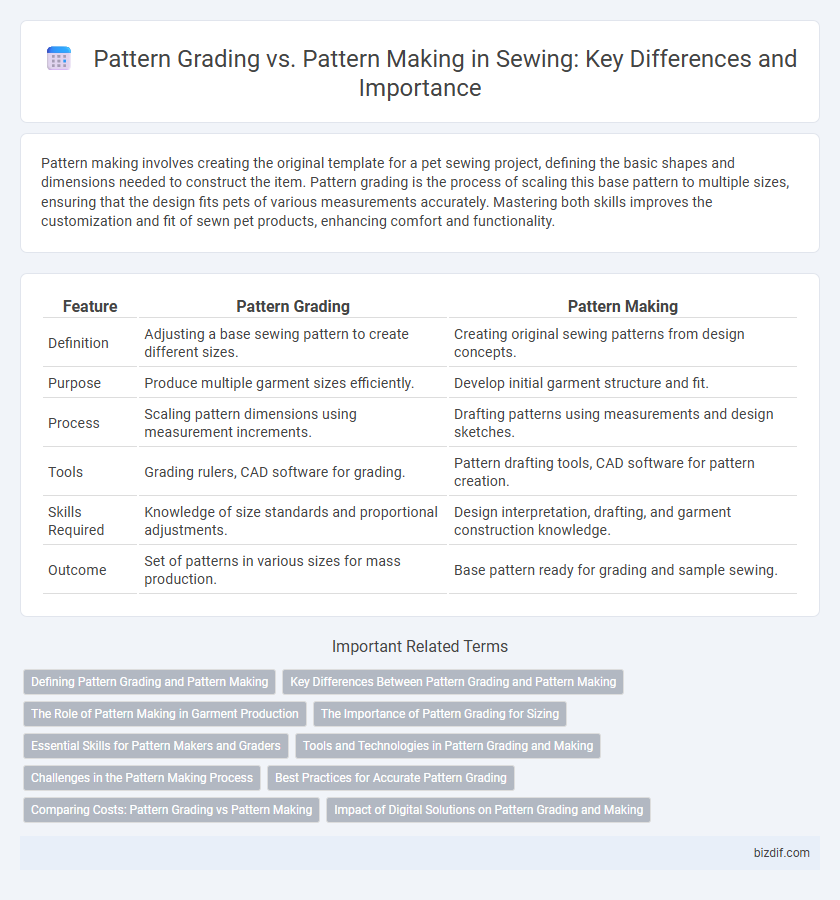

Pattern making involves creating the original template for a pet sewing project, defining the basic shapes and dimensions needed to construct the item. Pattern grading is the process of scaling this base pattern to multiple sizes, ensuring that the design fits pets of various measurements accurately. Mastering both skills improves the customization and fit of sewn pet products, enhancing comfort and functionality.

Table of Comparison

| Feature | Pattern Grading | Pattern Making |

|---|---|---|

| Definition | Adjusting a base sewing pattern to create different sizes. | Creating original sewing patterns from design concepts. |

| Purpose | Produce multiple garment sizes efficiently. | Develop initial garment structure and fit. |

| Process | Scaling pattern dimensions using measurement increments. | Drafting patterns using measurements and design sketches. |

| Tools | Grading rulers, CAD software for grading. | Pattern drafting tools, CAD software for pattern creation. |

| Skills Required | Knowledge of size standards and proportional adjustments. | Design interpretation, drafting, and garment construction knowledge. |

| Outcome | Set of patterns in various sizes for mass production. | Base pattern ready for grading and sample sewing. |

Defining Pattern Grading and Pattern Making

Pattern grading involves creating a series of different sizes from a base pattern to ensure consistent fit across various body measurements, using precise scaling techniques. Pattern making is the initial process of designing and drafting the original garment template based on specific style and measurement requirements. Mastery of both pattern grading and pattern making is essential for efficient apparel production and accurate garment fitting.

Key Differences Between Pattern Grading and Pattern Making

Pattern making involves creating the original design blueprint of a garment, establishing basic shapes and sizes from scratch using technical measurements. Pattern grading refers to the process of scaling this base pattern up or down to produce different sizes, ensuring consistent fit and proportion across a size range. The key difference lies in pattern making being the initial design development stage, while pattern grading adjusts those designs to accommodate various body dimensions.

The Role of Pattern Making in Garment Production

Pattern making serves as the foundation of garment production, translating design concepts into precise templates that dictate fabric cutting and assembly. It involves creating accurate patterns based on measurements and fit specifications, ensuring consistency and quality across multiple garment sizes. Effective pattern making streamlines the production process by reducing material waste and minimizing fitting errors, ultimately enhancing the efficiency and scalability of apparel manufacturing.

The Importance of Pattern Grading for Sizing

Pattern grading is essential for adapting sewing patterns to different sizes while maintaining the original design's proportions and fit accuracy. Precise grading techniques ensure garments accommodate diverse body measurements, improving comfort and appearance across size ranges. Effective pattern grading reduces production errors, streamlines manufacturing, and enhances the overall quality of ready-to-wear clothing lines.

Essential Skills for Pattern Makers and Graders

Pattern grading requires precise measurement scaling and an understanding of size increments to ensure consistent garment fit across multiple sizes, while pattern making focuses on creating the initial design template from scratch. Essential skills for pattern makers include strong spatial awareness, fabric knowledge, and proficiency in drafting tools or CAD software, enabling accurate and creative garment foundation development. Graders must excel in mathematical skills, attention to detail, and systematic thinking to adjust patterns without compromising design integrity.

Tools and Technologies in Pattern Grading and Making

Pattern grading utilizes digital tools such as CAD software and automated grading machines to efficiently scale base patterns across multiple sizes with precision. Pattern making often relies on both manual tools like rulers, curve templates, and drafting tables, as well as digital drafting programs for creating initial garment designs. Advanced technologies in pattern grading enable quicker adjustments and consistency, while pattern making emphasizes creativity and foundational pattern construction techniques.

Challenges in the Pattern Making Process

Pattern making involves creating the original template for garments, requiring precision in measurements and design translation, while pattern grading adjusts these templates to different sizes, maintaining fit and proportion. Challenges in pattern making include ensuring accurate fit across diverse body shapes, interpreting complex design details into flat patterns, and minimizing fabric waste through efficient layout planning. Mastery of advanced software and iterative prototyping is essential to overcome these obstacles and achieve functional, well-fitted garments.

Best Practices for Accurate Pattern Grading

Accurate pattern grading requires precise measurement scaling and consistent increment adjustments across all pattern pieces to maintain garment fit and proportion. Utilizing digital tools and software enhances precision and efficiency in pattern grading, reducing human errors common in manual processes. Best practices also include thorough sample testing and detailed documentation for replicability and quality control in the grading process.

Comparing Costs: Pattern Grading vs Pattern Making

Pattern grading involves resizing an existing sewing pattern to create multiple sizes, which typically lowers production costs due to reduced design time and repetition. Pattern making requires the initial creation of a new design pattern from scratch, often incurring higher costs due to the detailed drafting and fitting process. Evaluating costs between pattern grading and pattern making depends on project scale, with grading being more cost-effective for multi-size production runs.

Impact of Digital Solutions on Pattern Grading and Making

Digital solutions have revolutionized pattern grading and making by enhancing precision and efficiency through advanced CAD software, which allows for automated size adjustments and accurate pattern modifications. These technologies reduce manual errors and dramatically speed up the production process, enabling rapid prototyping and customization in garment manufacturing. Integration of 3D virtual fitting tools further improves the accuracy of pattern making, optimizing fabric usage and reducing waste in the apparel industry.

Pattern Grading vs Pattern Making Infographic

bizdif.com

bizdif.com