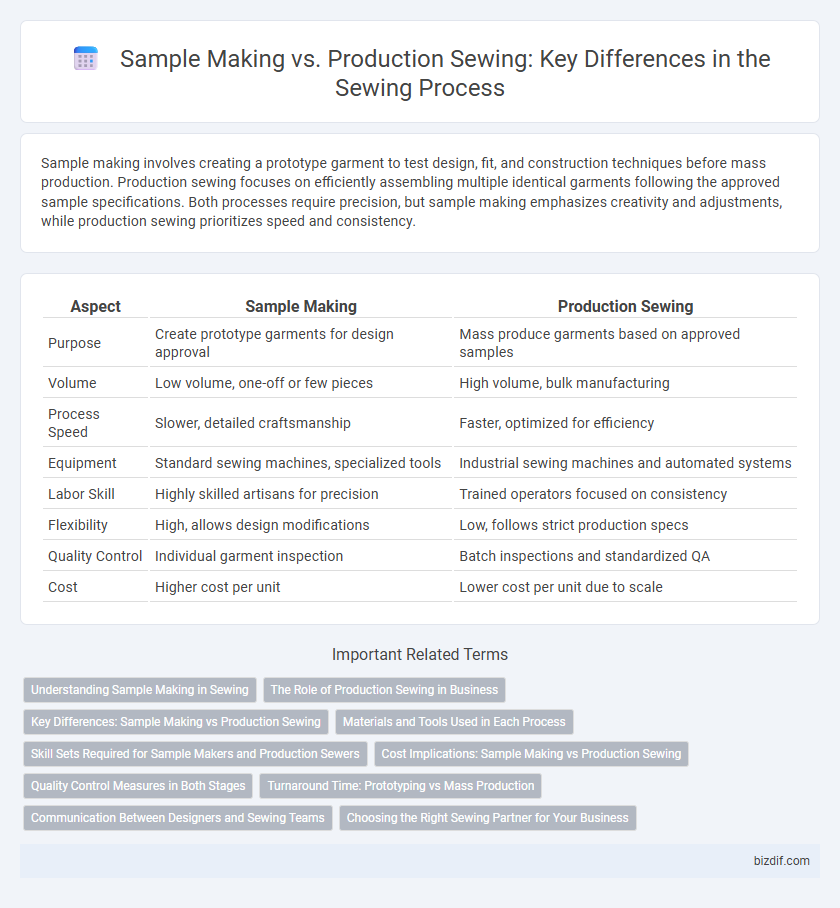

Sample making involves creating a prototype garment to test design, fit, and construction techniques before mass production. Production sewing focuses on efficiently assembling multiple identical garments following the approved sample specifications. Both processes require precision, but sample making emphasizes creativity and adjustments, while production sewing prioritizes speed and consistency.

Table of Comparison

| Aspect | Sample Making | Production Sewing |

|---|---|---|

| Purpose | Create prototype garments for design approval | Mass produce garments based on approved samples |

| Volume | Low volume, one-off or few pieces | High volume, bulk manufacturing |

| Process Speed | Slower, detailed craftsmanship | Faster, optimized for efficiency |

| Equipment | Standard sewing machines, specialized tools | Industrial sewing machines and automated systems |

| Labor Skill | Highly skilled artisans for precision | Trained operators focused on consistency |

| Flexibility | High, allows design modifications | Low, follows strict production specs |

| Quality Control | Individual garment inspection | Batch inspections and standardized QA |

| Cost | Higher cost per unit | Lower cost per unit due to scale |

Understanding Sample Making in Sewing

Sample making in sewing involves creating a prototype garment to test design, fit, and fabric choice before proceeding to mass production. This phase emphasizes precision and attention to detail to ensure the final product meets quality standards and design specifications. Understanding sample making is crucial for identifying potential issues early, reducing production costs, and streamlining the manufacturing process.

The Role of Production Sewing in Business

Production sewing plays a crucial role in scaling manufactured garments by ensuring consistent quality and efficiency across large batches. It involves standardized processes and specialized machinery to meet high-volume demands, reducing costs and lead times. Effective production sewing directly impacts profitability and customer satisfaction through reliable output and timely delivery.

Key Differences: Sample Making vs Production Sewing

Sample making involves creating a single prototype garment to test design details, fit, and fabric behavior, emphasizing precision and customization. Production sewing focuses on mass manufacturing of garments, prioritizing speed, consistency, and efficiency to meet large order volumes. While sample making requires skilled craftsmanship for unique pieces, production sewing relies on streamlined processes and standardized techniques for uniformity.

Materials and Tools Used in Each Process

Sample making in sewing involves using high-quality, often costly materials and specialized tools such as precision scissors, tailor's chalk, and fine needles to create a single prototype that accurately represents the final design. Production sewing focuses on cost-effective, durable fabrics and industrial-grade sewing machines designed for speed and volume, minimizing expenses while ensuring consistent quality across large batches. The key difference lies in the precision and material quality for sample making versus efficiency and scalability in production sewing.

Skill Sets Required for Sample Makers and Production Sewers

Sample makers require advanced pattern interpretation, precision in stitching, and problem-solving skills to create prototypes that reflect design intent accurately. Production sewers focus on speed, consistency, and efficiency to maintain high output while adhering to quality standards in mass garment manufacturing. Both roles demand a strong understanding of fabric properties, sewing techniques, and machine operation, but sample makers emphasize customization, whereas production sewers prioritize repetitive accuracy.

Cost Implications: Sample Making vs Production Sewing

Sample making incurs higher per-unit costs due to the need for precision, design adjustments, and trial runs, which require skilled labor and time-intensive processes. Production sewing benefits from economies of scale, significantly lowering costs as materials and labor are optimized for mass output. Understanding these cost implications helps manufacturers budget accurately and allocate resources efficiently between prototyping and full-scale garment production.

Quality Control Measures in Both Stages

Sample making emphasizes meticulous quality control measures, including detailed inspections of stitching accuracy, fabric alignment, and pattern fidelity to ensure design precision. Production sewing incorporates rigorous quality assessments at multiple stages, such as in-line inspections and final audits, to maintain consistency and detect defects across large volumes. Both stages rely on standardized quality control protocols, but sample making prioritizes prototype perfection while production sewing focuses on scalable quality assurance.

Turnaround Time: Prototyping vs Mass Production

Sample making in sewing typically requires a faster turnaround time focused on prototyping and design validation, often completed within days to a week. Production sewing for mass manufacturing involves longer lead times due to large volumes, quality checks, and process optimization, ranging from several weeks to months. Efficient workflow management in prototyping accelerates design iteration, whereas streamlined assembly lines optimize production sewing for consistent output.

Communication Between Designers and Sewing Teams

Effective communication between designers and sewing teams is crucial in both sample making and production sewing to ensure design accuracy and quality consistency. During sample making, clear, detailed feedback allows for rapid adjustments and refinement of prototypes before mass production. In production sewing, ongoing dialogue helps maintain adherence to specifications, prevent errors, and streamline workflow across multiple garment batches.

Choosing the Right Sewing Partner for Your Business

Selecting the right sewing partner involves understanding the distinct benefits of sample making and production sewing to match your business needs. Sample making requires precision and creativity to develop prototypes that align with design specifications, while production sewing emphasizes efficiency and scalability to meet large order demands. Evaluating a partner's expertise in both areas ensures consistent quality and timely delivery, critical for optimizing your manufacturing process.

Sample Making vs Production Sewing Infographic

bizdif.com

bizdif.com