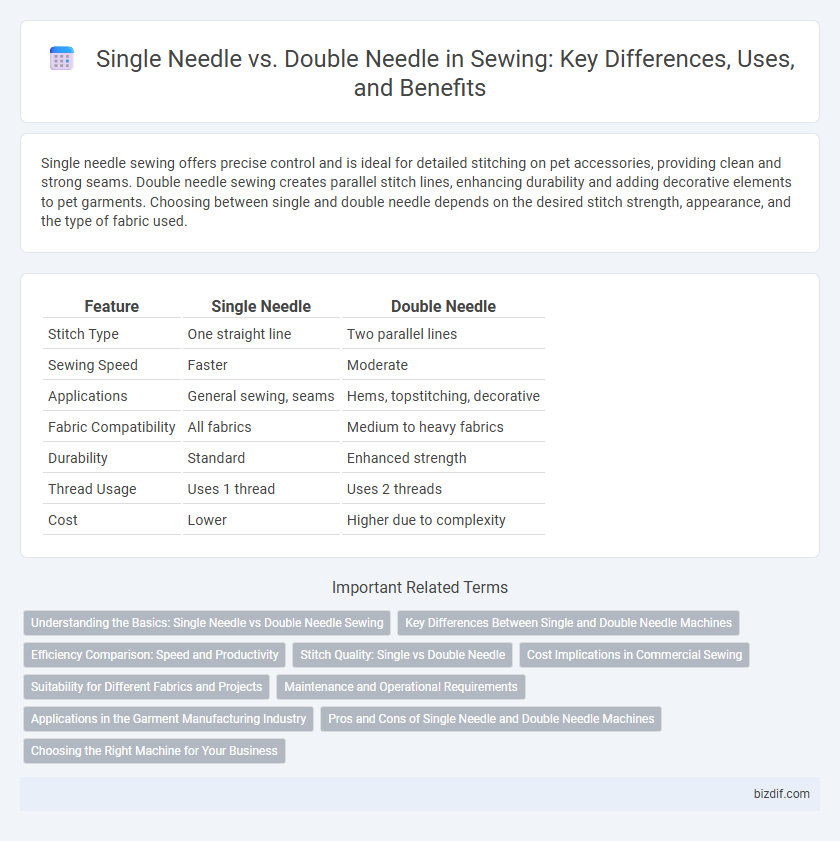

Single needle sewing offers precise control and is ideal for detailed stitching on pet accessories, providing clean and strong seams. Double needle sewing creates parallel stitch lines, enhancing durability and adding decorative elements to pet garments. Choosing between single and double needle depends on the desired stitch strength, appearance, and the type of fabric used.

Table of Comparison

| Feature | Single Needle | Double Needle |

|---|---|---|

| Stitch Type | One straight line | Two parallel lines |

| Sewing Speed | Faster | Moderate |

| Applications | General sewing, seams | Hems, topstitching, decorative |

| Fabric Compatibility | All fabrics | Medium to heavy fabrics |

| Durability | Standard | Enhanced strength |

| Thread Usage | Uses 1 thread | Uses 2 threads |

| Cost | Lower | Higher due to complexity |

Understanding the Basics: Single Needle vs Double Needle Sewing

Single needle sewing uses one needle to create a straight, sturdy stitch ideal for seams and detailed stitching, offering precision and control. Double needle sewing employs two needles simultaneously, producing parallel rows of stitches perfect for hemming, topstitching, and decorative finishes, enhancing durability and aesthetic appeal. Understanding these fundamental differences helps sewists select the appropriate technique for specific fabric types and project requirements.

Key Differences Between Single and Double Needle Machines

Single needle sewing machines feature one needle and are ideal for precise, detailed stitching and everyday sewing tasks, offering straightforward control and greater maneuverability. Double needle machines use two needles simultaneously, perfect for creating parallel rows of stitches, decorative patterns, and professional hems, enhancing efficiency in garment construction. Key differences include stitch versatility, speed, fabric handling capabilities, and suitability for different sewing projects, with double needle machines delivering stronger, more uniform stitches for heavy-duty work.

Efficiency Comparison: Speed and Productivity

Single needle sewing machines generally offer higher speed and greater precision for detailed stitching, enhancing overall efficiency in complex garment construction. Double needle machines increase productivity by simultaneously sewing two parallel seams, cutting down sewing time for consistent, repetitive tasks like hemming or topstitching. Choosing between single and double needle depends on balancing stitch accuracy with the need for accelerated production in industrial or home sewing environments.

Stitch Quality: Single vs Double Needle

Stitch quality with a single needle typically offers precision and neatness, making it ideal for detailed and delicate sewing tasks where tight, even stitches are required. Double needle stitching provides the advantage of parallel rows of stitches, enhancing durability and stretchability, especially useful for hems and knit fabrics. Choosing between single and double needle stitches depends on the desired strength, elasticity, and appearance of the finished seam.

Cost Implications in Commercial Sewing

Single needle sewing machines generally have lower upfront costs and reduced maintenance expenses, making them more cost-effective for small-scale operations or basic stitching tasks. Double needle machines, while initially more expensive, increase productivity by enabling simultaneous dual stitching, which reduces labor time and enhances garment durability in mass production settings. Investing in double needle machines often yields greater cost savings over time through increased output and fewer quality-related reworks in commercial sewing environments.

Suitability for Different Fabrics and Projects

Single needle sewing offers precision and control, making it ideal for delicate fabrics like silk, chiffon, and lightweight cotton, as well as detailed projects like garment tailoring and fine embroidery. Double needle sewing provides parallel stitching that is perfect for stretch fabrics such as knits and jersey, enhancing durability and elasticity in activewear and casual clothing. Choosing between single and double needle depends on fabric type and project requirements, balancing aesthetic finish with functional performance.

Maintenance and Operational Requirements

Single needle sewing machines require less frequent maintenance due to simpler mechanisms and fewer moving parts, reducing downtime and repair costs. Double needle machines demand more regular lubrication and careful alignment to ensure both needles operate smoothly and prevent skipped stitches or needle breakage. Operators of double needle machines should monitor tension settings more closely to maintain stitch consistency and avoid fabric damage.

Applications in the Garment Manufacturing Industry

Single needle machines excel in precision stitching for detailed garment construction and are ideal for seams requiring high strength and fine finishing, such as collars and cuffs. Double needle machines increase production efficiency by simultaneously sewing parallel lines, commonly used for hemming knitwear and creating decorative topstitching on jeans and t-shirts. The garment manufacturing industry leverages single needle machines for intricate, durable seams while employing double needle machines to enhance speed and aesthetic appeal in mass production.

Pros and Cons of Single Needle and Double Needle Machines

Single needle sewing machines offer precise stitching and are ideal for detailed work and heavy fabrics, providing better control and versatility for a variety of projects. Double needle machines increase efficiency by sewing two parallel stitches simultaneously, perfect for hemming and decorative seams, but they may be less flexible and more complex to operate. While single needle machines excel in precision and ease of use, double needle machines can save time but require more skill and are limited to specific stitch types.

Choosing the Right Machine for Your Business

Selecting the right sewing machine for your business hinges on the type and volume of work, where single needle machines offer precision and versatility for detailed stitching, while double needle machines increase productivity with parallel stitching ideal for hemming and topstitching. Single needle machines are preferred for intricate garment construction and quality finishes, whereas double needle machines excel in mass production environments requiring consistent, durable seams. Evaluating your business needs for stitch style, speed, and fabric compatibility ensures optimal investment and efficiency.

Single Needle vs Double Needle Infographic

bizdif.com

bizdif.com