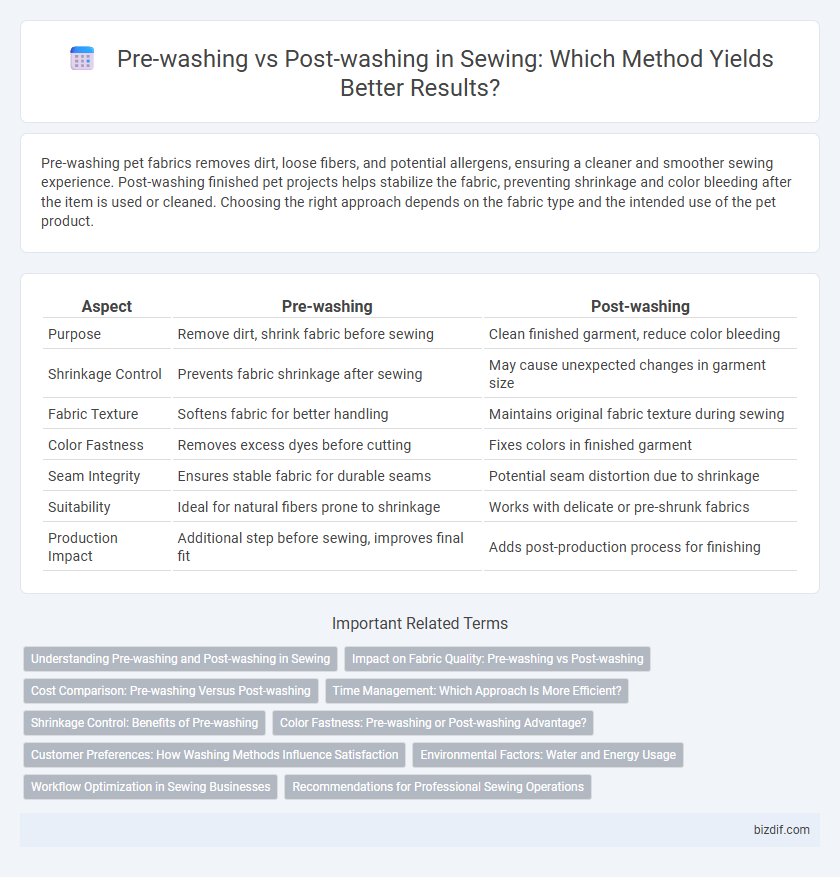

Pre-washing pet fabrics removes dirt, loose fibers, and potential allergens, ensuring a cleaner and smoother sewing experience. Post-washing finished pet projects helps stabilize the fabric, preventing shrinkage and color bleeding after the item is used or cleaned. Choosing the right approach depends on the fabric type and the intended use of the pet product.

Table of Comparison

| Aspect | Pre-washing | Post-washing |

|---|---|---|

| Purpose | Remove dirt, shrink fabric before sewing | Clean finished garment, reduce color bleeding |

| Shrinkage Control | Prevents fabric shrinkage after sewing | May cause unexpected changes in garment size |

| Fabric Texture | Softens fabric for better handling | Maintains original fabric texture during sewing |

| Color Fastness | Removes excess dyes before cutting | Fixes colors in finished garment |

| Seam Integrity | Ensures stable fabric for durable seams | Potential seam distortion due to shrinkage |

| Suitability | Ideal for natural fibers prone to shrinkage | Works with delicate or pre-shrunk fabrics |

| Production Impact | Additional step before sewing, improves final fit | Adds post-production process for finishing |

Understanding Pre-washing and Post-washing in Sewing

Pre-washing fabric involves washing the material before cutting and sewing to prevent shrinkage and color bleeding in finished garments. Post-washing occurs after the garment is sewn, allowing for final adjustments and often resulting in softer textures but with a higher risk of distortion. Understanding the differences helps sewists choose the right process to maintain garment size accuracy and fabric integrity.

Impact on Fabric Quality: Pre-washing vs Post-washing

Pre-washing fabrics removes excess dyes, shrinkage, and finishes, ensuring accurate garment sizing and reducing distortion after sewing. Post-washing may cause uncontrolled shrinkage or color bleeding, potentially damaging seams and altering fit. Choosing pre-washing improves durability and maintains fabric texture, while post-washing risks compromised fabric integrity and uneven appearance.

Cost Comparison: Pre-washing Versus Post-washing

Pre-washing fabric typically increases upfront costs due to water, detergent, and labor expenses, but it reduces risks of shrinkage and color bleeding during garment production, potentially saving money on rework and returns. Post-washing garments after sewing may lower initial expenses but can lead to higher costs from fabric distortion, fitting issues, and extra finishing processes. Evaluating cost-effectiveness depends on fabric type, production scale, and quality standards, with pre-washing often favored for minimizing defects and ensuring consistent sizing.

Time Management: Which Approach Is More Efficient?

Pre-washing fabric prevents shrinkage and dye bleeding during sewing but requires extra upfront time, potentially delaying project start. Post-washing saves initial preparation time but risks altering garment fit or color after completion, necessitating possible alterations. Efficient time management depends on fabric type and project goals, with pre-washing favored for natural fibers and post-washing suitable for quick prototypes or stable synthetics.

Shrinkage Control: Benefits of Pre-washing

Pre-washing fabric significantly reduces shrinkage, ensuring garments maintain their intended size and shape after washing. This process eliminates excess dyes and finishes that can cause fabric to contract, providing more accurate cutting and sewing measurements. By addressing shrinkage early, pre-washing helps achieve better fit and durability in finished sewing projects.

Color Fastness: Pre-washing or Post-washing Advantage?

Pre-washing fabrics enhances color fastness by removing excess dyes and preventing color bleeding during subsequent washes. Post-washing may cause colors to fade or bleed, especially with untreated or poorly dyed fabrics. Therefore, pre-washing is the preferred method to maintain vibrant and long-lasting colors in sewn garments.

Customer Preferences: How Washing Methods Influence Satisfaction

Customer preferences in sewing projects often hinge on the choice between pre-washing and post-washing fabrics, as these methods significantly influence final garment quality. Pre-washing removes excess dye and shrinkage potential, ensuring a stable fabric that enhances fit and comfort, which satisfies clients seeking durability. Post-washing often appeals to customers who prioritize vibrant colors and a softer feel, but may risk altered garment dimensions, affecting long-term satisfaction.

Environmental Factors: Water and Energy Usage

Pre-washing fabrics before sewing reduces shrinkage but increases water and energy consumption due to the added laundering step. Post-washing garments after sewing uses less water and energy since the entire item is cleaned at once, minimizing multiple wash cycles. Choosing post-washing aligns with eco-friendly practices by conserving resources and reducing the overall environmental footprint in textile production.

Workflow Optimization in Sewing Businesses

Pre-washing fabrics before sewing prevents shrinkage and color bleeding, ensuring accurate garment sizing and consistent quality which reduces costly rework and returns. Post-washing allows evaluation of final product durability and colorfastness, providing feedback for material and technique improvements in future production cycles. Integrating pre-washing into the cutting stage streamlines workflow by minimizing material waste, while strategic post-washing quality control enhances customer satisfaction and reduces defect rates.

Recommendations for Professional Sewing Operations

Professional sewing operations should prioritize pre-washing fabrics to avoid shrinkage and color bleeding that can compromise garment fit and finish. Pre-washing stabilizes the fabric, ensuring accurate pattern sizing and reducing production errors. Post-washing may be necessary for certain finished textiles but requires careful process controls to maintain product quality.

Pre-washing vs Post-washing Infographic

bizdif.com

bizdif.com