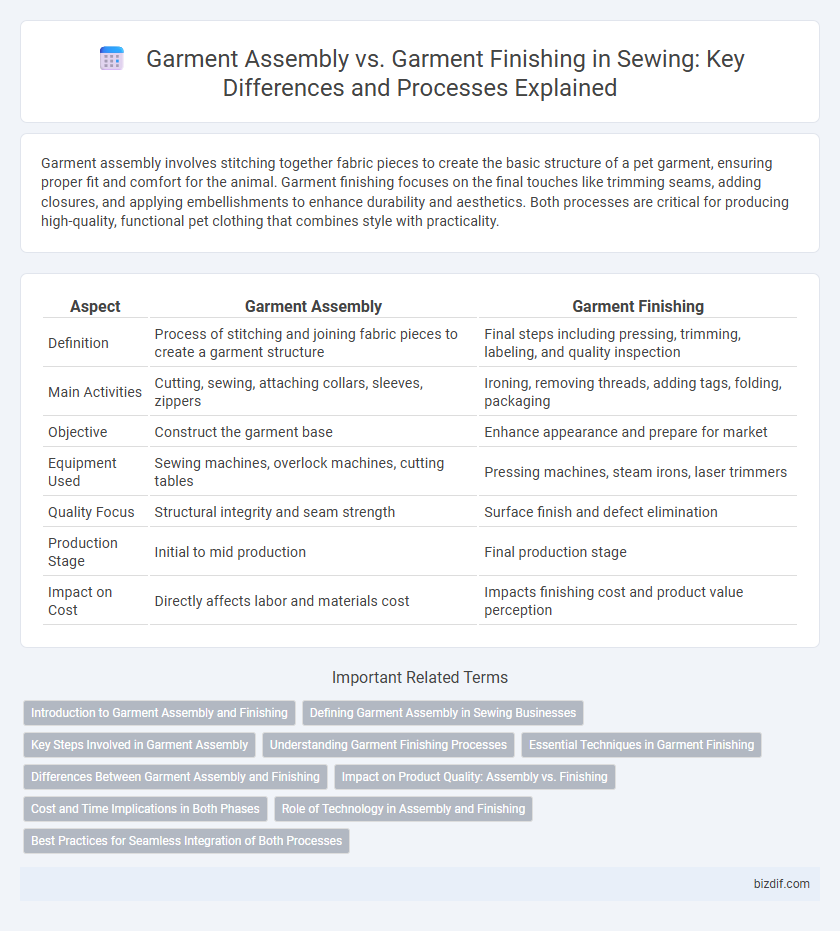

Garment assembly involves stitching together fabric pieces to create the basic structure of a pet garment, ensuring proper fit and comfort for the animal. Garment finishing focuses on the final touches like trimming seams, adding closures, and applying embellishments to enhance durability and aesthetics. Both processes are critical for producing high-quality, functional pet clothing that combines style with practicality.

Table of Comparison

| Aspect | Garment Assembly | Garment Finishing |

|---|---|---|

| Definition | Process of stitching and joining fabric pieces to create a garment structure | Final steps including pressing, trimming, labeling, and quality inspection |

| Main Activities | Cutting, sewing, attaching collars, sleeves, zippers | Ironing, removing threads, adding tags, folding, packaging |

| Objective | Construct the garment base | Enhance appearance and prepare for market |

| Equipment Used | Sewing machines, overlock machines, cutting tables | Pressing machines, steam irons, laser trimmers |

| Quality Focus | Structural integrity and seam strength | Surface finish and defect elimination |

| Production Stage | Initial to mid production | Final production stage |

| Impact on Cost | Directly affects labor and materials cost | Impacts finishing cost and product value perception |

Introduction to Garment Assembly and Finishing

Garment assembly involves stitching together various fabric pieces to create the basic shape of a garment, focusing on seam construction and structural integrity. Garment finishing enhances the appearance and functionality through processes like hemming, ironing, button attaching, and quality inspection. Efficient assembly and finishing are crucial for producing durable, aesthetically pleasing clothing that meets industry standards.

Defining Garment Assembly in Sewing Businesses

Garment assembly in sewing businesses involves the precise stitching and joining of fabric pieces to create a complete garment, ensuring structural integrity and fit. This stage includes operations such as seaming, hemming, and attaching components like sleeves, collars, and zippers. Effective garment assembly directly impacts production efficiency and garment quality before moving to garment finishing processes like pressing and trimming.

Key Steps Involved in Garment Assembly

Garment assembly involves key steps such as fabric cutting, stitching, joining panels, and attaching components like zippers and buttons to create the basic structure of the garment. Precision in seam alignment and consistent stitching quality are critical during this phase to ensure proper fit and durability. Unlike garment finishing, which focuses on pressing, trimming, and final inspection, garment assembly concentrates on constructing the garment's core form from individual fabric pieces.

Understanding Garment Finishing Processes

Garment finishing processes encompass critical steps such as pressing, trimming, labeling, and quality inspection that enhance the appearance and durability of the final product. These processes ensure seams are smooth, edges are clean, and the garment meets industry standards before reaching consumers. Mastery of garment finishing techniques directly impacts product appeal, customer satisfaction, and brand reputation.

Essential Techniques in Garment Finishing

Garment finishing encompasses essential techniques such as pressing, trimming, topstitching, and adding closures, which enhance the garment's appearance and durability. These processes ensure seam alignment, fabric shaping, and professional detailing that distinguish finished garments from assembled pieces. Proper garment finishing contributes to overall quality, fit, and wearability, making it a critical phase following garment assembly.

Differences Between Garment Assembly and Finishing

Garment assembly involves the initial construction phases where fabric pieces are stitched together to form the basic structure of the clothing item, focusing on seam alignment and durability. Garment finishing refers to post-assembly processes such as trimming, pressing, adding buttons or zippers, and quality inspections that enhance the garment's appearance and functionality. The primary difference lies in assembly creating the garment's core shape, while finishing refines and finalizes the product for market readiness.

Impact on Product Quality: Assembly vs. Finishing

Garment assembly directly affects product quality by ensuring accurate seam alignment, stitch strength, and structural integrity, which are critical for durability and fit. Garment finishing enhances the final appearance and feel through processes like pressing, trimming, and defect inspection, significantly influencing consumer perception and wearability. Both assembly and finishing stages jointly determine the overall garment quality, with assembly focusing on construction reliability and finishing on aesthetic refinement.

Cost and Time Implications in Both Phases

Garment assembly typically incurs higher labor costs and longer production times due to intricate stitching and component integration processes. In contrast, garment finishing involves comparatively lower expenses and faster turnaround, focusing on quality checks, trimming, pressing, and final touches. Efficient management of both phases is crucial to balance overall production costs and ensure timely delivery in the apparel manufacturing industry.

Role of Technology in Assembly and Finishing

Advanced computerized sewing machines and automated cutting systems play a crucial role in garment assembly by increasing precision and reducing production time. In garment finishing, technologies such as laser cutting, automated pressing, and computerized embroidery enhance quality control and reduce manual labor. Integration of Industry 4.0 technologies like IoT and AI enables real-time monitoring and optimization throughout both garment assembly and finishing processes.

Best Practices for Seamless Integration of Both Processes

Garment assembly involves stitching together fabric pieces to create the basic structure, while garment finishing focuses on final treatments like pressing, trimming, and adding embellishments to enhance appearance and durability. Best practices for seamless integration include implementing precise communication between assembly and finishing teams, scheduling workflows to minimize bottlenecks, and using quality control checkpoints at key stages. Leveraging technology such as automated sewing machines and finishing equipment ensures consistent quality and efficient transition from assembly to finishing.

Garment Assembly vs Garment Finishing Infographic

bizdif.com

bizdif.com