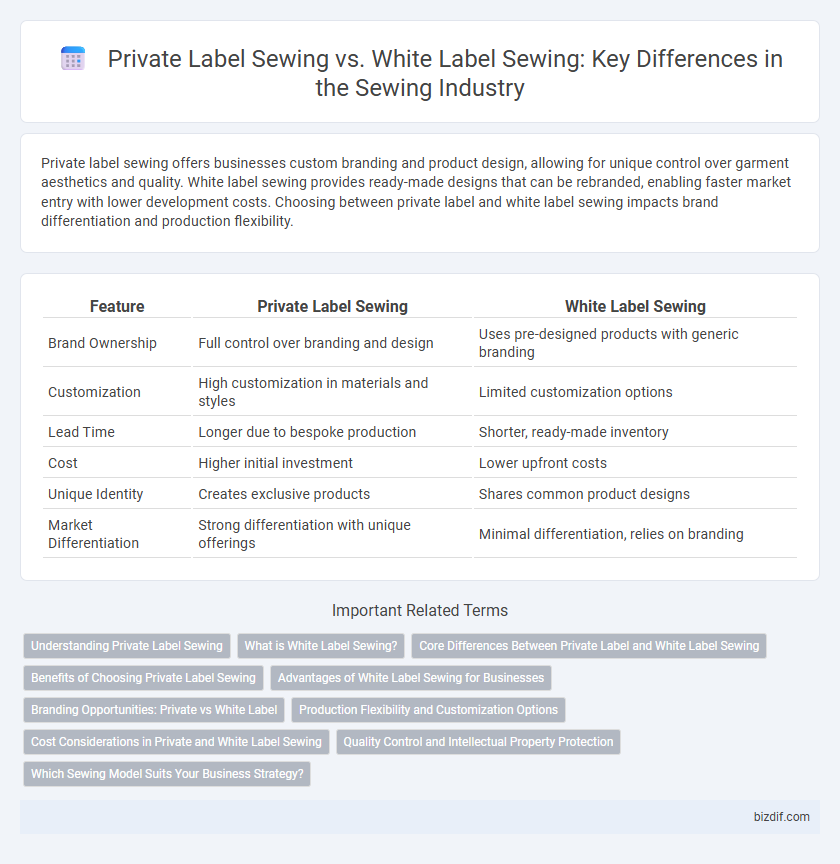

Private label sewing offers businesses custom branding and product design, allowing for unique control over garment aesthetics and quality. White label sewing provides ready-made designs that can be rebranded, enabling faster market entry with lower development costs. Choosing between private label and white label sewing impacts brand differentiation and production flexibility.

Table of Comparison

| Feature | Private Label Sewing | White Label Sewing |

|---|---|---|

| Brand Ownership | Full control over branding and design | Uses pre-designed products with generic branding |

| Customization | High customization in materials and styles | Limited customization options |

| Lead Time | Longer due to bespoke production | Shorter, ready-made inventory |

| Cost | Higher initial investment | Lower upfront costs |

| Unique Identity | Creates exclusive products | Shares common product designs |

| Market Differentiation | Strong differentiation with unique offerings | Minimal differentiation, relies on branding |

Understanding Private Label Sewing

Private label sewing involves creating custom garments exclusively designed and branded for a specific retailer or company, allowing full control over product design and quality standards. This approach enables businesses to develop unique fashion lines with distinct labels, fostering brand identity and market differentiation. Manufacturers collaborate closely with clients on fabric selection, sizing, and production details to ensure the final product aligns perfectly with the brand's vision and customer expectations.

What is White Label Sewing?

White Label Sewing refers to the process where manufacturers produce garments without branding, allowing retailers to market and sell the products under their own labels. This service enables businesses to quickly expand their clothing lines without investing in production facilities. White Label Sewing is ideal for companies seeking customizable, cost-effective apparel solutions with minimal lead time.

Core Differences Between Private Label and White Label Sewing

Private label sewing involves creating custom-designed garments exclusively for a specific brand, allowing complete control over product specifications, branding, and quality. White label sewing produces generic apparel items that multiple brands can rebrand and market as their own, with limited customization options. The core difference lies in ownership and uniqueness: private label ensures exclusivity and tailored production, while white label focuses on cost-efficiency and broad market availability.

Benefits of Choosing Private Label Sewing

Private label sewing allows brands to create unique, fully customizable apparel that aligns closely with their specific design and quality requirements, enhancing brand identity and customer loyalty. Choosing private label sewing offers greater control over fabric selection, tailoring, and production timelines, ensuring a differentiated product in a competitive market. This approach supports long-term brand growth by delivering exclusive designs that cannot be replicated by competitors using white label services.

Advantages of White Label Sewing for Businesses

White label sewing offers businesses the advantage of faster product launch times by providing ready-made designs that can be branded without the need for in-house development. This approach reduces upfront investment and manufacturing risks, allowing companies to focus resources on marketing and sales strategies. Moreover, white label sewing enables scalability and flexibility, as businesses can easily expand their product lines with minimal operational adjustments.

Branding Opportunities: Private vs White Label

Private label sewing offers brands complete control over product design, quality, and branding, allowing unique logos and custom packaging that enhance brand identity and consumer loyalty. White label sewing provides pre-made, generic products that can be rebranded under various company names, limiting customization but enabling faster market entry. The distinction in branding opportunities lies in private label's capacity for differentiation versus white label's efficiency and scalability for broad market reach.

Production Flexibility and Customization Options

Private label sewing offers greater production flexibility by allowing brands to customize patterns, fabrics, and design details tailored to their unique identity, enhancing brand differentiation. In contrast, white label sewing often involves standardized templates with limited customization, enabling faster turnaround but less individualization. Brands prioritizing distinctiveness and control over garment features typically prefer private label options, while those seeking cost-effective, ready-made solutions lean towards white label sewing.

Cost Considerations in Private and White Label Sewing

Private label sewing often involves higher upfront costs due to the need for custom designs, branding, and packaging tailored specifically to the client's specifications. White label sewing tends to be more cost-effective as it uses pre-existing designs and generic branding, reducing production complexities and expenses. Understanding these cost distinctions helps businesses choose the most efficient manufacturing approach aligned with budget constraints and market goals.

Quality Control and Intellectual Property Protection

Private label sewing emphasizes stringent quality control processes tailored to the brand's specifications, ensuring consistent product standards and customization. White label sewing offers faster production with pre-designed templates but may lack rigorous oversight, posing risks to quality consistency. Intellectual property protection is stronger in private label arrangements where designs are exclusive and legally safeguarded, unlike white label services that often recycle generic patterns for multiple clients.

Which Sewing Model Suits Your Business Strategy?

Private label sewing offers complete design control, allowing brands to customize patterns, fabrics, and labels for unique identity and market differentiation. White label sewing provides turnkey production of generic products that can be rebranded quickly, ideal for businesses prioritizing speed and cost-efficiency over customization. Choosing between private label and white label sewing depends on your business strategy's emphasis on exclusive branding versus rapid product launch and scalability.

Private Label Sewing vs White Label Sewing Infographic

bizdif.com

bizdif.com