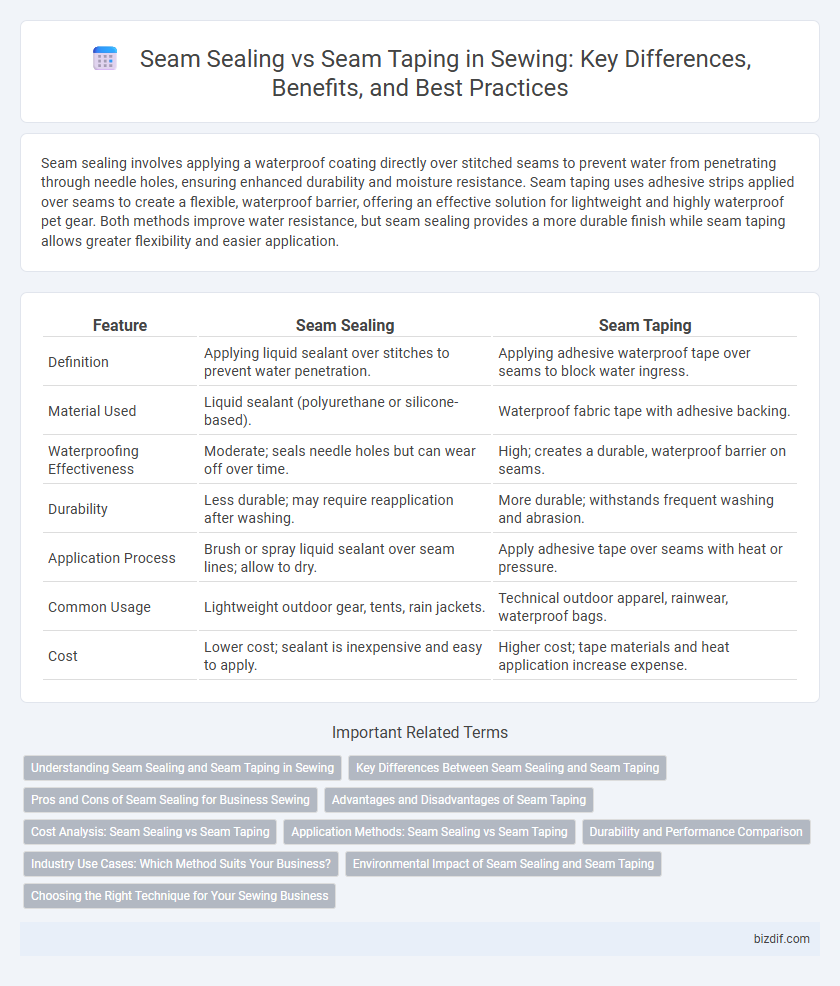

Seam sealing involves applying a waterproof coating directly over stitched seams to prevent water from penetrating through needle holes, ensuring enhanced durability and moisture resistance. Seam taping uses adhesive strips applied over seams to create a flexible, waterproof barrier, offering an effective solution for lightweight and highly waterproof pet gear. Both methods improve water resistance, but seam sealing provides a more durable finish while seam taping allows greater flexibility and easier application.

Table of Comparison

| Feature | Seam Sealing | Seam Taping |

|---|---|---|

| Definition | Applying liquid sealant over stitches to prevent water penetration. | Applying adhesive waterproof tape over seams to block water ingress. |

| Material Used | Liquid sealant (polyurethane or silicone-based). | Waterproof fabric tape with adhesive backing. |

| Waterproofing Effectiveness | Moderate; seals needle holes but can wear off over time. | High; creates a durable, waterproof barrier on seams. |

| Durability | Less durable; may require reapplication after washing. | More durable; withstands frequent washing and abrasion. |

| Application Process | Brush or spray liquid sealant over seam lines; allow to dry. | Apply adhesive tape over seams with heat or pressure. |

| Common Usage | Lightweight outdoor gear, tents, rain jackets. | Technical outdoor apparel, rainwear, waterproof bags. |

| Cost | Lower cost; sealant is inexpensive and easy to apply. | Higher cost; tape materials and heat application increase expense. |

Understanding Seam Sealing and Seam Taping in Sewing

Seam sealing involves applying a waterproof compound over stitched seams to prevent water penetration, while seam taping uses adhesive fabric strips to cover and reinforce seams for durability and waterproofing. Both techniques enhance garment performance, especially in outdoor and technical apparel, by providing moisture protection and improving seam strength. Selecting between seam sealing and seam taping depends on fabric type, garment use, and desired breathability.

Key Differences Between Seam Sealing and Seam Taping

Seam sealing involves applying a liquid or gel adhesive over stitched seams to waterproof fabric, creating a flexible yet durable barrier against moisture. Seam taping uses pre-cut waterproof tape applied over the seams to provide a strong, often more rigid protection that reinforces seam durability and prevents water penetration. Key differences include the application method--liquid coating versus adhesive tape--and the flexibility and durability of the finished seam treatment in waterproof garments.

Pros and Cons of Seam Sealing for Business Sewing

Seam sealing enhances water resistance by applying a waterproof coating over stitched seams, making it ideal for outdoor and performance garments. It offers flexibility and durability but can increase production time and costs, potentially impacting large-scale business efficiency. Businesses must weigh the improved product quality against higher labor and material expenses when considering seam sealing.

Advantages and Disadvantages of Seam Taping

Seam taping provides a highly effective waterproof barrier by applying adhesive fabric strips over stitched seams, enhancing garment durability in wet conditions. The main advantage lies in its strong adhesion and flexibility, allowing for breathable protection without adding significant bulk, making it ideal for outdoor gear. However, seam taping can degrade over time with repeated washing and exposure to heat, and improper application may result in peeling or reduced waterproofing performance.

Cost Analysis: Seam Sealing vs Seam Taping

Seam sealing generally incurs higher material and labor costs due to the use of specialized sealing compounds and the meticulous application process. Seam taping is often more cost-effective, utilizing adhesive-backed fabric strips that speed up production and reduce labor expenses. Both methods enhance waterproofing, but seam taping offers a budget-friendly advantage for mass production without compromising durability.

Application Methods: Seam Sealing vs Seam Taping

Seam sealing involves applying a liquid waterproof adhesive directly over stitched seams to prevent water penetration, often using a brush or roller for precise coverage. Seam taping uses pre-cut waterproof tapes that are heat-activated or pressure-applied over seams, providing a durable and flexible barrier. Both methods enhance garment waterproofing but differ in application technique and flexibility, impacting breathability and durability in outdoor apparel.

Durability and Performance Comparison

Seam sealing involves applying a waterproof coating directly over stitched seams, offering superior water resistance and durability on outdoor gear exposed to harsh conditions. Seam taping uses adhesive-backed fabric strips applied inside the seams, providing reliable performance but often less longevity under repeated flexing and washing. Choosing between seam sealing and seam taping depends on the specific performance needs, with seam sealing favored for high-durability applications and seam taping suited for moderate use and easier manufacturing.

Industry Use Cases: Which Method Suits Your Business?

Seam sealing provides a waterproof barrier by applying a liquid sealant over stitched seams, making it essential for outdoor gear manufacturers requiring high water resistance. Seam taping uses adhesive fabric strips applied over seams for durability and flexibility, preferred by apparel brands focusing on breathable, lightweight garments. Businesses producing rainwear, tents, or protective clothing benefit from seam sealing, while sportswear and casual apparel industries often favor seam taping for comfort and enhanced fabric performance.

Environmental Impact of Seam Sealing and Seam Taping

Seam sealing and seam taping both enhance waterproofing but differ significantly in environmental impact; seam sealing often uses solvent-based adhesives that release volatile organic compounds (VOCs), contributing to air pollution and health risks. Seam taping utilizes synthetic tapes bonded with hot-melt adhesives, which can incorporate recyclable or eco-friendly materials, reducing chemical emissions but potentially increasing plastic waste. Choosing eco-conscious materials and production methods in either technique can mitigate environmental harm by lowering carbon footprint and improving garment durability.

Choosing the Right Technique for Your Sewing Business

Seam sealing involves applying a waterproof coating directly over stitched seams, ideal for outdoor gear that requires full water resistance, while seam taping uses adhesive-backed fabric strips to cover seams, offering durability and breathability for activewear. Choosing the right technique depends on the product's intended use, material type, and required performance standards, with seam sealing best for heavy-duty waterproofing and seam taping preferred for lighter, flexible garments. Evaluating fabric compatibility, customer needs, and production costs ensures the most effective method, optimizing both product quality and business profitability.

Seam sealing vs seam taping Infographic

bizdif.com

bizdif.com