Lean manufacturing in sewing pet products emphasizes waste reduction, continuous improvement, and streamlined workflows, leading to faster production times and higher quality output. Traditional production often involves batch processing with greater material waste, longer lead times, and less flexibility in customization. Adopting lean principles allows manufacturers to optimize resource use and respond more quickly to market demands.

Table of Comparison

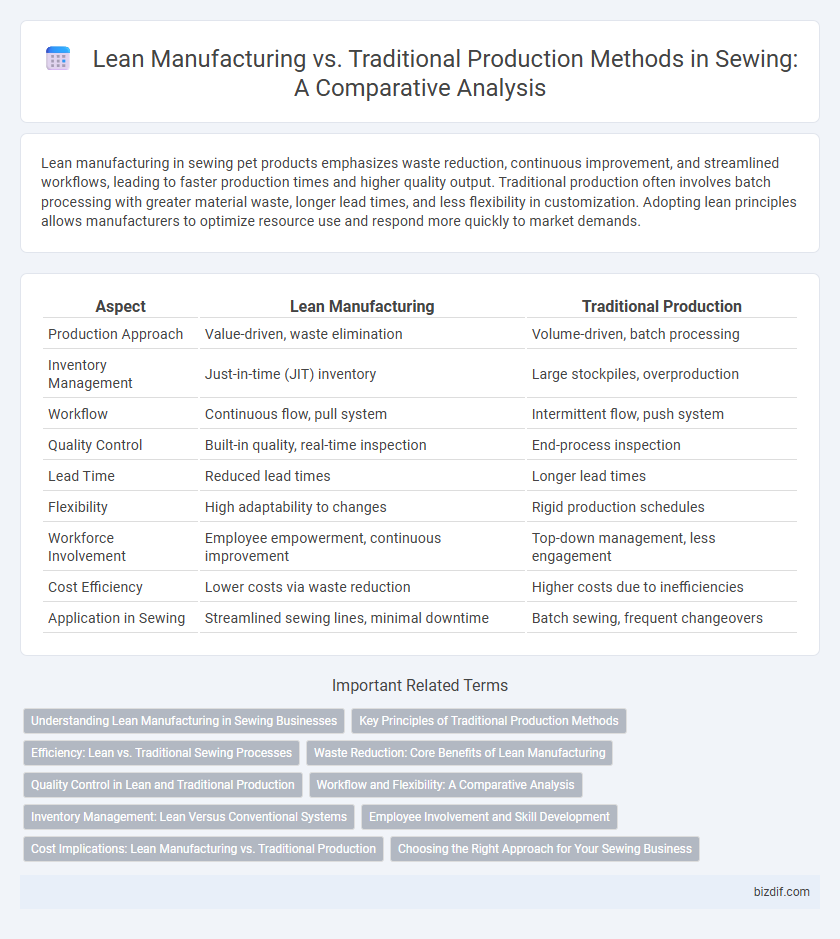

| Aspect | Lean Manufacturing | Traditional Production |

|---|---|---|

| Production Approach | Value-driven, waste elimination | Volume-driven, batch processing |

| Inventory Management | Just-in-time (JIT) inventory | Large stockpiles, overproduction |

| Workflow | Continuous flow, pull system | Intermittent flow, push system |

| Quality Control | Built-in quality, real-time inspection | End-process inspection |

| Lead Time | Reduced lead times | Longer lead times |

| Flexibility | High adaptability to changes | Rigid production schedules |

| Workforce Involvement | Employee empowerment, continuous improvement | Top-down management, less engagement |

| Cost Efficiency | Lower costs via waste reduction | Higher costs due to inefficiencies |

| Application in Sewing | Streamlined sewing lines, minimal downtime | Batch sewing, frequent changeovers |

Understanding Lean Manufacturing in Sewing Businesses

Lean manufacturing in sewing businesses emphasizes eliminating waste, optimizing workflow, and improving fabric utilization to increase efficiency. Traditional production often involves batch processing and excess inventory, which can lead to higher costs and longer lead times. Implementing lean principles in sewing operations streamlines cutting, stitching, and finishing processes, resulting in faster turnaround and reduced material waste.

Key Principles of Traditional Production Methods

Traditional production methods in sewing emphasize batch processing, where garments are produced in large quantities through sequential stages, often resulting in higher inventory levels and longer lead times. The focus on specialization means workers perform specific, repetitive tasks, which may limit flexibility but enhances consistency and skill in individual operations. Hierarchical control structures dominate, prioritizing strict supervision and standardized procedures over employee involvement or continuous process improvements.

Efficiency: Lean vs. Traditional Sewing Processes

Lean manufacturing in sewing significantly boosts efficiency by minimizing waste through continuous workflow and just-in-time production techniques, enabling faster turnaround and reduced inventory costs. Traditional sewing processes rely heavily on batch production, often leading to longer lead times and excess material usage due to rigid workflows and less flexibility. Lean sewing methods optimize labor utilization and machine operation, yielding higher productivity and consistent quality while traditional methods may struggle with inefficiencies and variability.

Waste Reduction: Core Benefits of Lean Manufacturing

Lean manufacturing in sewing significantly reduces waste by streamlining fabric usage and minimizing defects, leading to cost savings and higher efficiency. Unlike traditional production, which often produces excess inventory and scrap, lean methods emphasize continuous improvement and precise resource allocation. This waste reduction not only enhances environmental sustainability but also improves overall production speed and product quality.

Quality Control in Lean and Traditional Production

Lean manufacturing emphasizes continuous quality control through real-time defect detection and immediate corrective actions, reducing waste and minimizing rework. Traditional production relies on post-production inspection, increasing the likelihood of defects reaching the customer and higher costs associated with reprocessing. Implementing Lean quality control tools such as poka-yoke and standardized work enhances sewing accuracy and consistency compared to conventional batch inspection methods.

Workflow and Flexibility: A Comparative Analysis

Lean manufacturing in sewing emphasizes streamlined workflow through continuous process improvement and waste reduction, resulting in faster cycle times and minimal downtime. Traditional production often follows rigid, linear workflows with limited flexibility, leading to slower adjustments and higher work-in-progress inventory. Lean systems incorporate modular workstations and cross-trained operators, enhancing adaptability to changing orders and reducing setup times substantially.

Inventory Management: Lean Versus Conventional Systems

Lean manufacturing in sewing emphasizes just-in-time inventory, minimizing stock levels to reduce waste and storage costs, thereby enhancing production flow and responsiveness. Conventional inventory management relies on larger buffer stocks to prevent production delays, often resulting in excess materials and higher carrying costs. Optimizing inventory through lean principles leads to improved cash flow and agility in meeting fluctuating customer demands.

Employee Involvement and Skill Development

Lean manufacturing in sewing emphasizes continuous employee involvement and skill development through collaborative problem-solving and cross-functional training, enhancing productivity and reducing errors. Traditional production often relies on repetitive tasks with limited worker autonomy, resulting in slower skill growth and less engagement. Investing in employee development under lean principles fosters adaptability and innovation, crucial for maintaining high-quality standards in garment manufacturing.

Cost Implications: Lean Manufacturing vs. Traditional Production

Lean manufacturing in sewing significantly reduces costs by minimizing waste, improving fabric utilization, and streamlining workflows, leading to lower material and labor expenses compared to traditional production methods. Traditional production often incurs higher costs due to excess inventory, longer setup times, and inefficient resource use, resulting in increased overhead and slower turnaround. Implementing lean techniques enhances cost efficiency by optimizing cutting processes, reducing defects, and accelerating garment delivery times, creating substantial savings across the sewing production cycle.

Choosing the Right Approach for Your Sewing Business

Lean manufacturing in sewing emphasizes waste reduction, continuous workflow, and efficient resource use, leading to faster production cycles and lowered costs. Traditional production methods often involve batch processing, resulting in higher inventory levels and longer lead times. Selecting the best approach requires evaluating your sewing business's volume, customization needs, and operational flexibility to maximize productivity and profitability.

Lean manufacturing vs traditional production Infographic

bizdif.com

bizdif.com