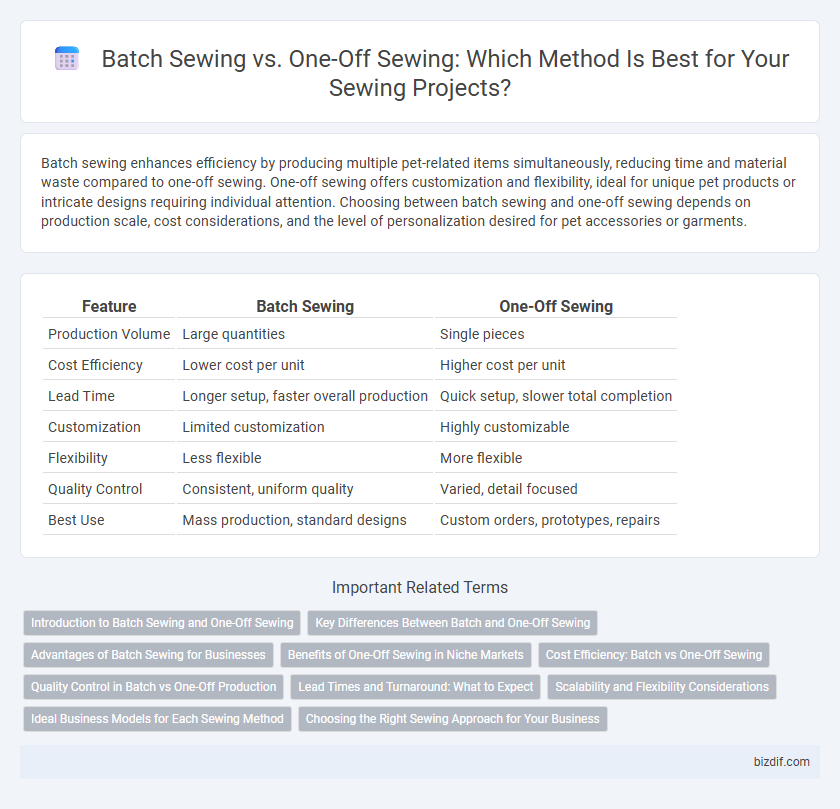

Batch sewing enhances efficiency by producing multiple pet-related items simultaneously, reducing time and material waste compared to one-off sewing. One-off sewing offers customization and flexibility, ideal for unique pet products or intricate designs requiring individual attention. Choosing between batch sewing and one-off sewing depends on production scale, cost considerations, and the level of personalization desired for pet accessories or garments.

Table of Comparison

| Feature | Batch Sewing | One-Off Sewing |

|---|---|---|

| Production Volume | Large quantities | Single pieces |

| Cost Efficiency | Lower cost per unit | Higher cost per unit |

| Lead Time | Longer setup, faster overall production | Quick setup, slower total completion |

| Customization | Limited customization | Highly customizable |

| Flexibility | Less flexible | More flexible |

| Quality Control | Consistent, uniform quality | Varied, detail focused |

| Best Use | Mass production, standard designs | Custom orders, prototypes, repairs |

Introduction to Batch Sewing and One-Off Sewing

Batch sewing involves producing multiple identical garments or products in a single production run, enhancing efficiency and consistency by minimizing setup time and material waste. One-off sewing focuses on creating single custom pieces tailored to specific requirements, allowing for high personalization and flexibility but often requiring more time per unit. Both methods cater to different market needs, with batch sewing suited for large-scale manufacturing and one-off sewing ideal for bespoke or prototype creation.

Key Differences Between Batch and One-Off Sewing

Batch sewing involves producing multiple identical garments simultaneously, optimizing efficiency with consistent fabric cutting and repetitive stitching processes. One-off sewing focuses on creating a single custom or prototype piece, requiring greater flexibility and detailed attention to individual garment specifications. Key differences include production scale, cost-effectiveness, and time investment, with batch sewing suited for mass production and one-off sewing ideal for bespoke or sample pieces.

Advantages of Batch Sewing for Businesses

Batch sewing enhances production efficiency by allowing businesses to complete large quantities of identical garments simultaneously, significantly reducing labor and material costs. This method improves consistency in quality and fit across products, strengthening brand reliability and customer satisfaction. Bulk handling of fabrics and trims during batch production also lowers wastage, optimizing overall resource management for manufacturers.

Benefits of One-Off Sewing in Niche Markets

One-off sewing offers unparalleled customization, allowing niche markets to meet specific customer demands with unique designs and precise measurements. Small production runs reduce inventory costs and minimize waste, making it ideal for limited-edition or bespoke garments. This tailored approach enhances brand exclusivity and customer satisfaction, strengthening market differentiation.

Cost Efficiency: Batch vs One-Off Sewing

Batch sewing reduces production costs by allowing manufacturers to purchase materials in bulk and streamline labor, leading to lower per-unit expenses compared to one-off sewing. One-off sewing incurs higher costs due to frequent machine setups and limited economies of scale, making it less cost-effective for large orders. Businesses aiming for cost efficiency typically prefer batch sewing for mass production, while one-off sewing suits customized, small-quantity projects despite the higher price per item.

Quality Control in Batch vs One-Off Production

Batch sewing enables more consistent quality control through standardized processes applied across multiple garments, reducing variability and defects. One-off sewing, by contrast, demands intense individual attention for each piece, allowing greater customization but posing challenges in maintaining uniform quality. Implementing robust quality checks in batch production enhances efficiency, while one-off sewing relies heavily on skilled craftsmanship to uphold standards.

Lead Times and Turnaround: What to Expect

Batch sewing offers shorter lead times due to the production of multiple garments simultaneously, allowing manufacturers to streamline processes and reduce setup times. One-off sewing typically involves longer turnaround because each piece requires individual attention and machine adjustments, increasing production time per item. Businesses should anticipate faster delivery with batch sewing when consistency is key, while one-off projects provide customization at the expense of extended lead times.

Scalability and Flexibility Considerations

Batch sewing offers enhanced scalability by enabling production of large quantities with consistent quality, making it ideal for businesses aiming to meet high demand efficiently. One-off sewing provides unparalleled flexibility, allowing customization and quick adjustments for unique or small-order projects without extensive setup. Balancing these approaches depends on production needs, where batch sewing optimizes volume and cost-efficiency while one-off sewing supports personalized designs and rapid prototyping.

Ideal Business Models for Each Sewing Method

Batch sewing excels in businesses requiring consistent production volume, such as apparel manufacturers or uniform suppliers, due to its efficiency and cost-effectiveness. One-off sewing suits bespoke tailors or custom fashion designers who prioritize unique, high-quality garments tailored to individual clients. Choosing between batch and one-off sewing depends on factors like order volume, customization needs, and production timelines, making batch sewing ideal for mass production and one-off sewing optimal for personalized creations.

Choosing the Right Sewing Approach for Your Business

Batch sewing increases efficiency and reduces material costs by producing multiple identical garments at once, making it ideal for businesses with consistent demand and larger order volumes. One-off sewing offers flexibility and customization, perfect for bespoke items or small-scale production where unique designs and rapid turnaround are priorities. Evaluating order size, production timeline, and design complexity helps determine whether batch or one-off sewing best aligns with your business goals and resource capacity.

Batch Sewing vs One-Off Sewing Infographic

bizdif.com

bizdif.com