Flatlock stitch creates a smooth, flat seam ideal for sewing pet garments without bulk, enhancing comfort and flexibility for active pets. Overlock stitch efficiently trims fabric edges while simultaneously sewing them, providing durable and stretchable seams that resist wear and tear. Both stitches improve the durability and appearance of pet clothing, but flatlock is better for seamless comfort while overlock excels in edge finishing and strength.

Table of Comparison

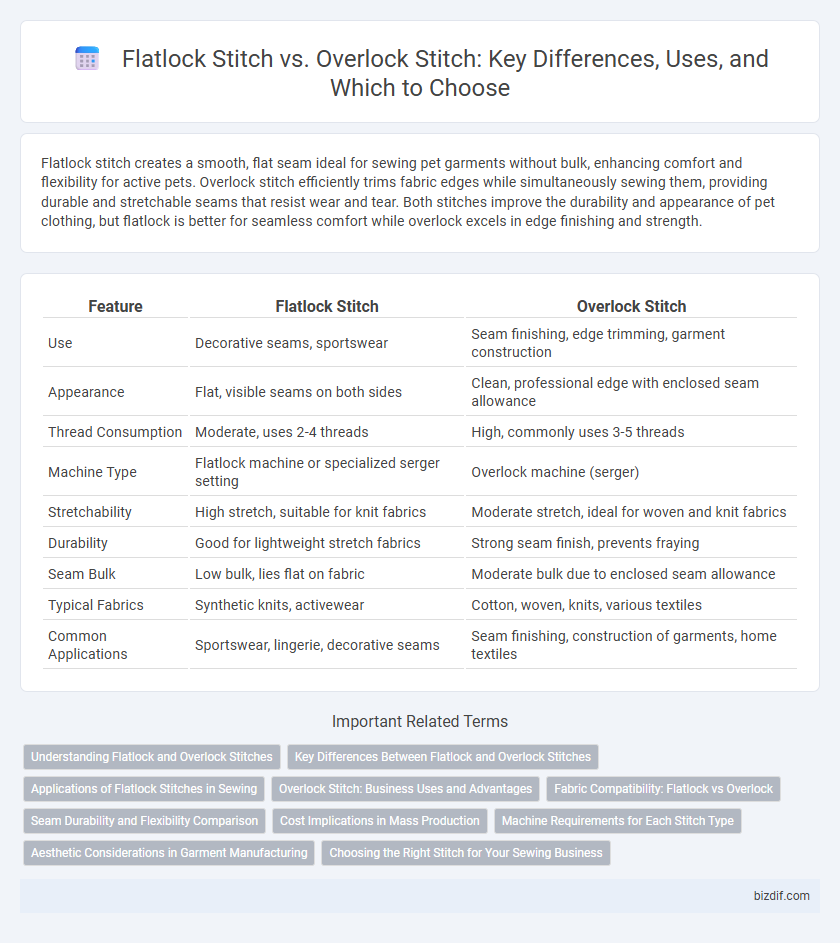

| Feature | Flatlock Stitch | Overlock Stitch |

|---|---|---|

| Use | Decorative seams, sportswear | Seam finishing, edge trimming, garment construction |

| Appearance | Flat, visible seams on both sides | Clean, professional edge with enclosed seam allowance |

| Thread Consumption | Moderate, uses 2-4 threads | High, commonly uses 3-5 threads |

| Machine Type | Flatlock machine or specialized serger setting | Overlock machine (serger) |

| Stretchability | High stretch, suitable for knit fabrics | Moderate stretch, ideal for woven and knit fabrics |

| Durability | Good for lightweight stretch fabrics | Strong seam finish, prevents fraying |

| Seam Bulk | Low bulk, lies flat on fabric | Moderate bulk due to enclosed seam allowance |

| Typical Fabrics | Synthetic knits, activewear | Cotton, woven, knits, various textiles |

| Common Applications | Sportswear, lingerie, decorative seams | Seam finishing, construction of garments, home textiles |

Understanding Flatlock and Overlock Stitches

Flatlock stitches create a smooth, flat seam by joining fabric edges edge-to-edge, ideal for activewear and stretch fabrics due to their flexibility and minimal bulk. Overlock stitches simultaneously trim, sew, and finish the fabric edges, preventing fraying and providing a strong, durable seam commonly used in garment construction and knitwear. Understanding the differences helps in selecting the appropriate stitch for fabric type, seam strength, and desired garment finish.

Key Differences Between Flatlock and Overlock Stitches

Flatlock stitches create a flat seam by joining two pieces of fabric edge-to-edge, ideal for decorative seams and activewear due to their flexibility and low bulk. Overlock stitches encase the fabric edges with thread, preventing fraying and providing a strong, durable finish commonly used in garment construction. The key difference lies in flatlock's seam flatness and stretch versus overlock's edge finishing and seam strength.

Applications of Flatlock Stitches in Sewing

Flatlock stitches are commonly used in activewear and sports garments due to their ability to create strong, flexible seams that lie flat against the skin, reducing chafing and enhancing comfort. These stitches are ideal for sewing stretchy fabrics like spandex and jersey, making them popular in swimwear, leggings, and compression clothing. Their decorative and functional properties also make flatlock seams suitable for visible topstitching on casual and athletic apparel.

Overlock Stitch: Business Uses and Advantages

Overlock stitch is widely used in the garment manufacturing industry for its ability to efficiently sew, trim, and finish fabric edges in a single pass, significantly speeding up production. This stitch enhances seam strength and elasticity, making it ideal for knitwear, activewear, and stretch fabrics, where durability and flexibility are crucial. Its clean finish prevents fraying, reduces the need for additional hemming, and supports high-volume production runs, boosting overall cost-effectiveness and product quality in commercial sewing operations.

Fabric Compatibility: Flatlock vs Overlock

Flatlock stitches are ideal for stretch fabrics like knits and athletic wear, providing smooth, flat seams that reduce bulk and increase comfort. Overlock stitches work well on woven fabrics and medium-weight materials, efficiently finishing raw edges and preventing fraying. Choosing between flatlock and overlock depends on fabric type and desired seam strength and flexibility.

Seam Durability and Flexibility Comparison

Flatlock stitches provide exceptional seam durability and flexibility, making them ideal for activewear and stretch fabrics by creating a flat, low-profile seam that reduces irritation and allows for greater movement. Overlock stitches deliver strong, secure seam finishes with excellent edge protection, preventing fraying and maintaining structural integrity under stress, but they tend to be less flexible than flatlock seams. Choosing between flatlock and overlock stitches depends on the desired balance between stretchability and strength for specific sewing projects.

Cost Implications in Mass Production

Flatlock stitch offers cost savings in mass production by reducing thread usage and minimizing fabric bulk, leading to lower material expenses and faster sewing cycles. Overlock stitch, while providing strong edge finishing and seam durability, often incurs higher operational costs due to specialized machines and increased thread consumption. Manufacturers must weigh the economical benefits of flatlock stitching against the durability and quality demands met by overlock stitching when optimizing production budgets.

Machine Requirements for Each Stitch Type

Flatlock stitch requires a specialized flatlock sewing machine or a serger with a differential feed and multiple needles to create smooth, flat seams ideal for stretch fabrics. Overlock stitch demands an overlock machine equipped with loopers and cutter blades to trim fabric edges while simultaneously stitching, ensuring durable finishes and preventing fraying. Both machine types vary in complexity and cost, with flatlock machines primarily used in athletic and activewear production and overlock machines serving broader garment construction needs.

Aesthetic Considerations in Garment Manufacturing

Flatlock stitch creates a smooth, flat seam ideal for visible garment areas, providing a clean, decorative finish without bulk. Overlock stitch secures fabric edges efficiently but results in a bulkier seam that is less visually appealing for outerwear details. Designers often choose flatlock stitching for sportswear and activewear to enhance both comfort and aesthetic appeal.

Choosing the Right Stitch for Your Sewing Business

Flatlock stitch provides a strong, flexible seam ideal for sportswear and stretch fabrics, while overlock stitch offers efficient edge finishing and seam trimming suited for mass production. Choosing the right stitch depends on fabric type, desired seam strength, and production speed requirements. Investing in machines that support both stitching methods maximizes versatility and quality in your sewing business.

Flatlock Stitch vs Overlock Stitch Infographic

bizdif.com

bizdif.com