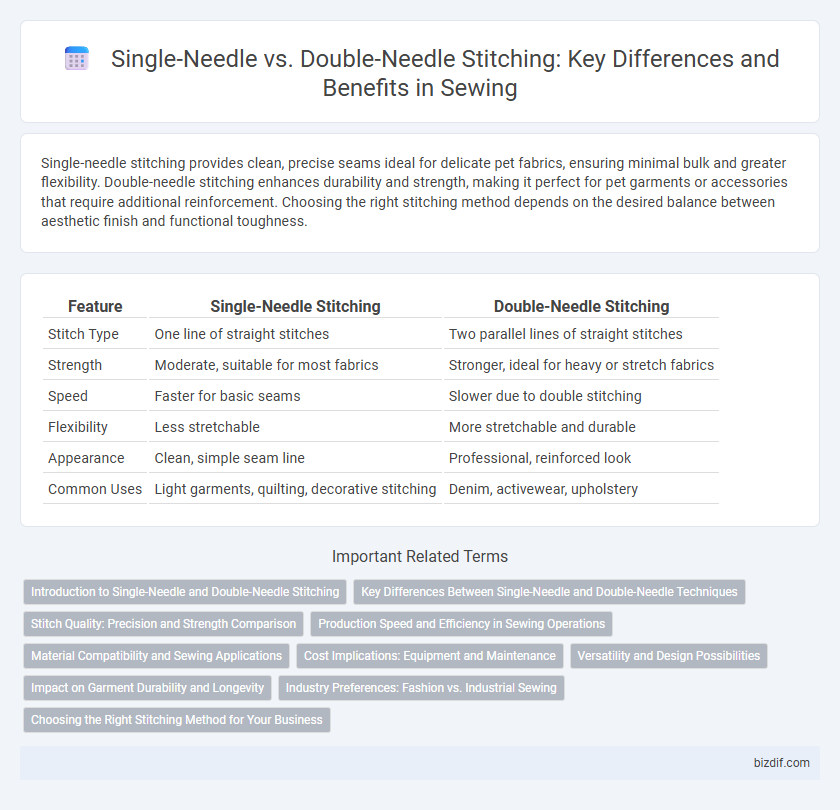

Single-needle stitching provides clean, precise seams ideal for delicate pet fabrics, ensuring minimal bulk and greater flexibility. Double-needle stitching enhances durability and strength, making it perfect for pet garments or accessories that require additional reinforcement. Choosing the right stitching method depends on the desired balance between aesthetic finish and functional toughness.

Table of Comparison

| Feature | Single-Needle Stitching | Double-Needle Stitching |

|---|---|---|

| Stitch Type | One line of straight stitches | Two parallel lines of straight stitches |

| Strength | Moderate, suitable for most fabrics | Stronger, ideal for heavy or stretch fabrics |

| Speed | Faster for basic seams | Slower due to double stitching |

| Flexibility | Less stretchable | More stretchable and durable |

| Appearance | Clean, simple seam line | Professional, reinforced look |

| Common Uses | Light garments, quilting, decorative stitching | Denim, activewear, upholstery |

Introduction to Single-Needle and Double-Needle Stitching

Single-needle stitching uses one needle to create a straight, precise seam ideal for detailed sewing tasks and fine fabrics. Double-needle stitching employs two needles, forming parallel rows of stitches that enhance durability and provide a professional finish for hems and decorative topstitching. Both techniques are essential in garment construction, offering distinct strengths depending on fabric type and design requirements.

Key Differences Between Single-Needle and Double-Needle Techniques

Single-needle stitching uses one needle and thread, producing a clean, precise seam ideal for detailed and delicate fabrics. Double-needle stitching employs two needles simultaneously, creating parallel rows of stitching that enhance durability and provide a decorative finish, commonly used in hems and knitwear. The primary differences lie in stitch strength, fabric compatibility, and the visual appeal of the seam.

Stitch Quality: Precision and Strength Comparison

Single-needle stitching offers higher precision with tighter, cleaner stitches ideal for detailed work and delicate fabrics, ensuring minimal distortion. Double-needle stitching provides enhanced strength and durability by creating parallel rows of stitches, effectively reinforcing seams in heavy-duty or stretch materials. The choice between single-needle and double-needle stitching directly impacts garment longevity and appearance, with single-needle excelling in finesse and double-needle maximizing seam resilience.

Production Speed and Efficiency in Sewing Operations

Single-needle stitching offers faster production speeds due to its simpler setup and quicker thread changes, making it ideal for high-volume sewing operations. Double-needle stitching increases efficiency by simultaneously creating two parallel seams, reducing overall sewing time while enhancing seam strength in garment manufacturing. Choosing between single-needle and double-needle stitching depends on balancing production speed requirements with the desired durability and stitch style in industrial sewing workflows.

Material Compatibility and Sewing Applications

Single-needle stitching excels with delicate fabrics like silk and lightweight cotton, providing precision and minimizing fabric distortion, making it ideal for tailored garments and detailed seams. Double-needle stitching suits heavier materials such as denim and canvas, offering enhanced durability and parallel seam strength, commonly used in sportswear and upholstery. Choosing between single-needle and double-needle stitching depends on material thickness and desired seam reinforcement for specific sewing applications.

Cost Implications: Equipment and Maintenance

Single-needle stitching machines generally have lower upfront costs and simpler maintenance requirements, making them more affordable for small-scale sewing operations. Double-needle stitching machines, while more expensive initially, offer increased productivity and durability, which can reduce long-term maintenance expenses. Cost efficiency depends on the volume of production and the complexity of sewing tasks involved.

Versatility and Design Possibilities

Single-needle stitching offers precise control for intricate designs and is ideal for detailed seam work, while double-needle stitching enhances durability and creates parallel lines perfect for decorative hems and topstitching. Double-needle stitching increases versatility by allowing simultaneous dual-thread combinations, expanding creative design possibilities. Both techniques contribute unique aesthetic and functional qualities, enabling tailored garment construction and diverse customization options.

Impact on Garment Durability and Longevity

Single-needle stitching offers precision and a clean finish, resulting in garments with higher durability due to fewer thread overlaps and reduced fabric stress. Double-needle stitching reinforces seams with parallel lines of thread, enhancing strength and minimizing the risk of seam failure, which significantly extends garment longevity. Choosing between these techniques depends on the balance between aesthetic preference and the required durability for specific garment types.

Industry Preferences: Fashion vs. Industrial Sewing

Fashion industry favors single-needle stitching for its precision and clean finish, essential for high-quality garment construction and detailed designs. Industrial sewing prioritizes double-needle stitching due to its durability and efficiency, enabling faster production with reinforced seams suited for heavy-duty fabrics. The choice between single and double-needle stitching reflects the balance between aesthetic appeal and functional strength demanded by each sector.

Choosing the Right Stitching Method for Your Business

Choosing between single-needle stitching and double-needle stitching depends on your business needs, fabric type, and desired durability. Single-needle stitching offers precision and a cleaner finish, ideal for detailed designs and lightweight fabrics, while double-needle stitching provides enhanced strength and is suitable for heavy-duty garments and high-stress seams. Evaluating production volume, cost-effectiveness, and end-use will help determine the most efficient stitching method for quality and scalability.

Single-needle stitching vs Double-needle stitching Infographic

bizdif.com

bizdif.com