Industrial sewing machines offer superior speed, durability, and precision, making them ideal for large-scale pet product manufacturing. Home sewing machines provide greater flexibility and ease of use for custom, small-batch pet items but often lack the power needed for heavy-duty materials. Choosing between industrial and home sewing depends on the volume, material complexity, and specific needs of the pet project.

Table of Comparison

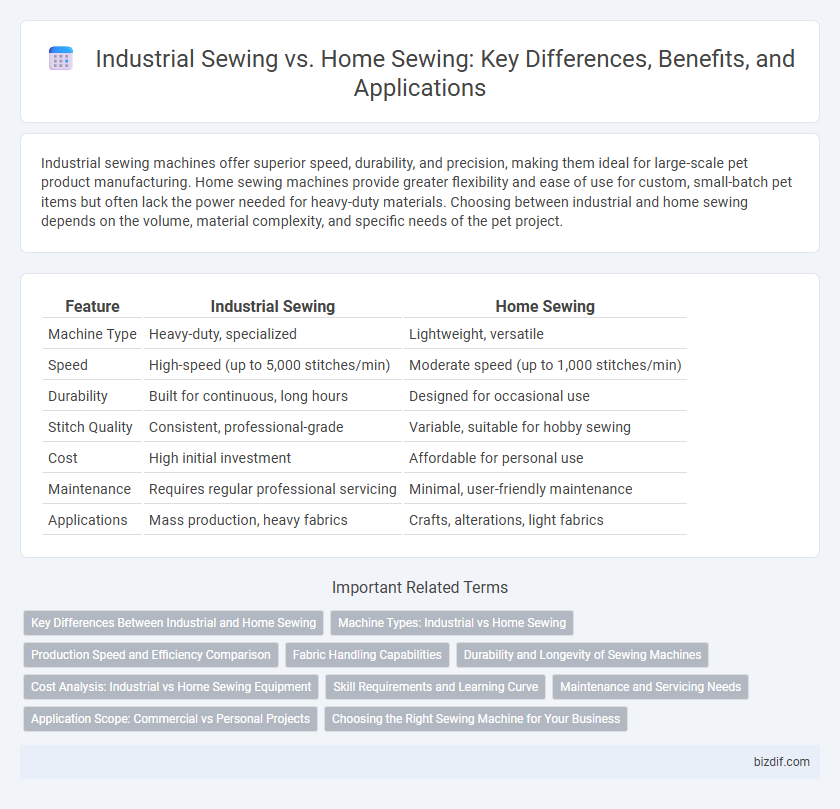

| Feature | Industrial Sewing | Home Sewing |

|---|---|---|

| Machine Type | Heavy-duty, specialized | Lightweight, versatile |

| Speed | High-speed (up to 5,000 stitches/min) | Moderate speed (up to 1,000 stitches/min) |

| Durability | Built for continuous, long hours | Designed for occasional use |

| Stitch Quality | Consistent, professional-grade | Variable, suitable for hobby sewing |

| Cost | High initial investment | Affordable for personal use |

| Maintenance | Requires regular professional servicing | Minimal, user-friendly maintenance |

| Applications | Mass production, heavy fabrics | Crafts, alterations, light fabrics |

Key Differences Between Industrial and Home Sewing

Industrial sewing machines are designed for high-speed production with durable, heavy-duty components capable of handling thick fabrics and continuous use, whereas home sewing machines focus on versatility and ease of use for lighter materials and varied stitch types. Industrial machines typically feature a more powerful motor, larger work area, and automated functions that increase efficiency in garment manufacturing, while home machines prioritize portability and user-friendly controls suitable for hobbyists. The stitching quality of industrial machines is often more consistent due to precise tension control and advanced feed mechanisms compared to standard home machines.

Machine Types: Industrial vs Home Sewing

Industrial sewing machines are designed for high-speed, continuous operation with specialized components like heavy-duty motors and metal parts that ensure durability and precision in mass production. Home sewing machines offer versatility with features tailored for diverse fabric types and ease of use, typically incorporating computerized controls and lighter, compact designs suited for occasional or hobby sewing. The choice between industrial and home sewing machines depends on the volume of work, fabric complexity, and the need for speed and robustness in manufacturing environments versus flexibility and convenience in household projects.

Production Speed and Efficiency Comparison

Industrial sewing machines deliver significantly higher production speed and efficiency compared to home sewing machines, handling heavy-duty fabrics and continuous operation without overheating. These machines feature advanced automation, multiple needle configurations, and programmable settings that streamline repetitive tasks in manufacturing environments. Conversely, home sewing machines prioritize versatility and ease of use but operate at slower speeds and require frequent breaks to prevent motor strain, limiting output capacity.

Fabric Handling Capabilities

Industrial sewing machines excel in fabric handling capabilities, effortlessly managing heavy-duty and multiple layered materials like leather, denim, and canvas with consistent stitch quality. Home sewing machines are designed for lighter fabrics such as cotton, silk, and polyester and may struggle with thick or bulky textiles, often requiring manual adjustments or slower sewing speeds. Enhanced feed mechanisms and stronger motors in industrial machines ensure smooth fabric movement and precision on complex material types.

Durability and Longevity of Sewing Machines

Industrial sewing machines are engineered with heavy-duty components designed to withstand high-volume production, ensuring exceptional durability and extended lifespan compared to home sewing machines. Home sewing machines focus on versatility and ease of use but often feature lighter parts that may wear out faster under intense or continuous use. Investing in an industrial sewing machine guarantees consistent performance and longevity in demanding sewing environments.

Cost Analysis: Industrial vs Home Sewing Equipment

Industrial sewing equipment generally demands a higher initial investment, ranging from $1,000 to $6,000 or more per machine, compared to home sewing machines typically priced between $100 and $1,000. Maintenance and operational costs for industrial machines tend to be elevated due to their heavy-duty components and frequent use in production settings, whereas home machines incur lower upkeep expenses suitable for occasional sewing tasks. Evaluating total cost of ownership requires factoring in production volume, with industrial machines offering greater long-term value for high-output environments despite their upfront expense.

Skill Requirements and Learning Curve

Industrial sewing demands advanced skills, including proficiency with specialized machines and consistent speed, often requiring formal training or apprenticeships for mastery. Home sewing features a gentler learning curve, focusing on basic stitching techniques that hobbyists can acquire through tutorials and practice. Mastery in industrial sewing leads to higher precision and productivity, while home sewing emphasizes creativity and flexibility.

Maintenance and Servicing Needs

Industrial sewing machines require frequent maintenance and professional servicing due to their high-speed operation and continuous use in manufacturing environments. Home sewing machines typically need less intensive upkeep, with occasional cleaning and lubrication sufficing for optimal performance. Proper maintenance of both machine types ensures longevity, but industrial models demand more specialized care to prevent costly downtime.

Application Scope: Commercial vs Personal Projects

Industrial sewing machines are designed to handle large-scale commercial projects, providing high-speed stitching and durable performance ideal for mass production in garment factories and upholstery workshops. Home sewing machines cater to personal projects, offering versatility and ease of use for crafting, alterations, and small-scale garment creation. The application scope distinguishes industrial sewing by its efficiency and heavy-duty capacity, while home sewing emphasizes customization and hobbyist creativity.

Choosing the Right Sewing Machine for Your Business

Selecting the right sewing machine for your business depends on volume, fabric type, and project complexity, with industrial machines offering high-speed performance and durability for heavy-duty tasks, while home machines provide versatility and portability for smaller-scale work. Industrial sewing machines excel in consistent stitch quality and can handle thick materials like leather and denim, making them ideal for mass production environments. Evaluating your production needs and budget ensures you invest in a machine that maximizes efficiency and supports business growth.

Industrial Sewing vs Home Sewing Infographic

bizdif.com

bizdif.com