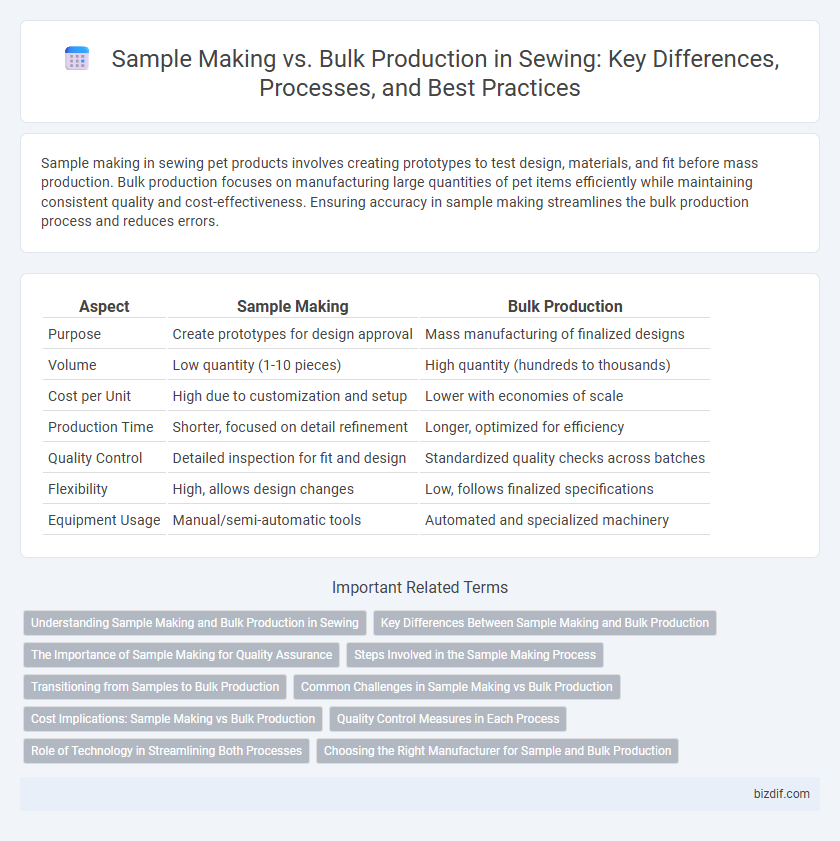

Sample making in sewing pet products involves creating prototypes to test design, materials, and fit before mass production. Bulk production focuses on manufacturing large quantities of pet items efficiently while maintaining consistent quality and cost-effectiveness. Ensuring accuracy in sample making streamlines the bulk production process and reduces errors.

Table of Comparison

| Aspect | Sample Making | Bulk Production |

|---|---|---|

| Purpose | Create prototypes for design approval | Mass manufacturing of finalized designs |

| Volume | Low quantity (1-10 pieces) | High quantity (hundreds to thousands) |

| Cost per Unit | High due to customization and setup | Lower with economies of scale |

| Production Time | Shorter, focused on detail refinement | Longer, optimized for efficiency |

| Quality Control | Detailed inspection for fit and design | Standardized quality checks across batches |

| Flexibility | High, allows design changes | Low, follows finalized specifications |

| Equipment Usage | Manual/semi-automatic tools | Automated and specialized machinery |

Understanding Sample Making and Bulk Production in Sewing

Sample making in sewing involves creating a prototype garment to test design accuracy, fabric compatibility, and fit before mass manufacturing. Bulk production follows once the sample meets quality standards, enabling large-scale output with consistent stitching, fabric cutting, and assembly processes. Efficient coordination between sample approval and bulk production minimizes errors and production delays, ensuring timely delivery of finished garments.

Key Differences Between Sample Making and Bulk Production

Sample making involves creating a prototype garment to test design, fit, and fabric, typically produced in small quantities with high attention to detail. Bulk production focuses on mass manufacturing, emphasizing efficiency, cost-effectiveness, and uniformity across large volumes. Key differences include production scale, quality control standards, time requirements, and material sourcing strategies.

The Importance of Sample Making for Quality Assurance

Sample making serves as a critical step in sewing by allowing manufacturers to evaluate garment design, fit, and fabric quality before bulk production begins. This process helps identify potential defects and ensures adherence to specifications, reducing costly errors and material waste. High-quality sample making ultimately guarantees product consistency and customer satisfaction in large-scale production.

Steps Involved in the Sample Making Process

Sample making in sewing involves initial design interpretation, fabric selection, and creating a prototype garment to test fit, style, and construction techniques. This process includes pattern drafting, cutting, sewing the first sample, and conducting quality checks to ensure accuracy before bulk production. Adjustments based on fitting sessions and feedback are critical to refining the sample for mass manufacturing.

Transitioning from Samples to Bulk Production

Transitioning from sample making to bulk production requires precise quality control to maintain consistency across all units. Efficient communication between designers and manufacturers ensures that specifications from the sample are accurately replicated in mass production. Implementing thorough testing during the sample phase minimizes errors and reduces costly adjustments during bulk manufacturing.

Common Challenges in Sample Making vs Bulk Production

Sample making often faces challenges such as limited material availability and precise fit adjustments, which require meticulous attention to detail. Bulk production struggles with maintaining consistent quality and managing large-scale supply chain logistics to meet deadlines. Variations in machine calibration and labor skill levels frequently cause discrepancies between sample prototypes and final mass-produced garments.

Cost Implications: Sample Making vs Bulk Production

Sample making typically involves higher per-unit costs due to the labor-intensive process and the use of unique materials, whereas bulk production benefits from economies of scale, significantly reducing the cost per garment. Cost implications of sample making include expenses for prototype development, adjustments, and testing, which are necessary to ensure quality and fit before mass production. Bulk production lowers overall expenses by allowing manufacturers to purchase materials in larger quantities and streamline labor, ultimately improving profit margins.

Quality Control Measures in Each Process

Sample making involves meticulous quality control measures, including detailed inspections of stitch consistency, fabric alignment, and material defects to ensure the prototype meets design specifications. Bulk production emphasizes systematic quality control through statistical process control, random sampling, and real-time defect detection to maintain uniformity and reduce errors across large quantities. Both stages require distinct quality protocols, with sample making focusing on precision and bulk production prioritizing efficiency and consistency.

Role of Technology in Streamlining Both Processes

Technology enhances precision and efficiency in sample making by utilizing 3D design software and automated cutting machines, reducing material waste and turnaround time. In bulk production, advanced robotics and computerized sewing systems increase consistency, speed, and scalability while minimizing human error. Digital integration across both stages enables seamless communication, real-time quality control, and faster decision-making in garment manufacturing.

Choosing the Right Manufacturer for Sample and Bulk Production

Selecting the right manufacturer for sample making and bulk production is crucial to ensure quality and consistency in sewing projects. Sample making requires a manufacturer skilled in prototyping and flexible adjustments, while bulk production demands a partner with scalable operations and reliable timelines. Prioritizing manufacturers with proven expertise, advanced machinery, and strong quality control systems guarantees efficient transition from sample creation to mass production.

Sample Making vs Bulk Production Infographic

bizdif.com

bizdif.com