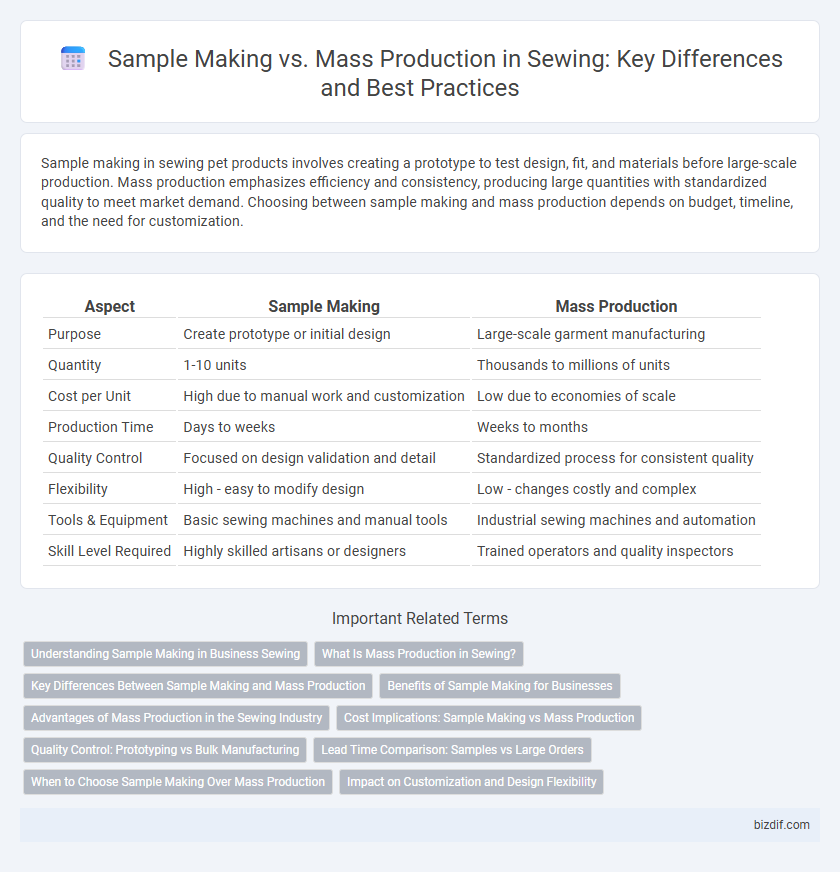

Sample making in sewing pet products involves creating a prototype to test design, fit, and materials before large-scale production. Mass production emphasizes efficiency and consistency, producing large quantities with standardized quality to meet market demand. Choosing between sample making and mass production depends on budget, timeline, and the need for customization.

Table of Comparison

| Aspect | Sample Making | Mass Production |

|---|---|---|

| Purpose | Create prototype or initial design | Large-scale garment manufacturing |

| Quantity | 1-10 units | Thousands to millions of units |

| Cost per Unit | High due to manual work and customization | Low due to economies of scale |

| Production Time | Days to weeks | Weeks to months |

| Quality Control | Focused on design validation and detail | Standardized process for consistent quality |

| Flexibility | High - easy to modify design | Low - changes costly and complex |

| Tools & Equipment | Basic sewing machines and manual tools | Industrial sewing machines and automation |

| Skill Level Required | Highly skilled artisans or designers | Trained operators and quality inspectors |

Understanding Sample Making in Business Sewing

Sample making in business sewing is the initial stage where prototypes of garments are created to evaluate design, fit, and fabric choice before large-scale manufacturing. This process allows designers and manufacturers to identify and resolve potential issues, optimize production methods, and ensure quality standards. Investing time and resources in precise sample making reduces costly errors and enhances efficiency during mass production.

What Is Mass Production in Sewing?

Mass production in sewing refers to the large-scale manufacturing of garments using standardized patterns and automated machinery to ensure high efficiency and consistency. This process significantly reduces production time and costs by producing thousands of identical items in assembly-line workflows. Factories specializing in mass production use advanced cutting machines, industrial sewing machines, and quality control systems to maintain uniformity across all pieces.

Key Differences Between Sample Making and Mass Production

Sample making involves creating a single garment prototype to evaluate design, fit, and fabric choice, while mass production focuses on manufacturing large quantities of identical garments efficiently. The sample stage allows for adjustments and quality control, ensuring the final product meets specifications before committing to full-scale production. Mass production requires optimized workflows, standardized patterns, and quality assurance systems to maintain consistency across thousands of units.

Benefits of Sample Making for Businesses

Sample making enables businesses to evaluate design accuracy, fabric quality, and construction techniques before committing to large-scale production, reducing costly errors and material waste. It facilitates client approval and feedback, ensuring product alignment with market preferences and brand standards. Early prototype development helps streamline production timelines, improve inventory management, and enhance overall product quality in mass manufacturing.

Advantages of Mass Production in the Sewing Industry

Mass production in the sewing industry ensures consistent quality and reduces unit costs by utilizing standardized processes and automated machinery, enhancing efficiency and output scale. This method enables faster turnaround times, meeting large-volume demand and minimizing labor expenses per garment. Economies of scale achieved through mass production also facilitate competitive pricing, making it ideal for global apparel brands targeting mass markets.

Cost Implications: Sample Making vs Mass Production

Sample making incurs higher per-unit costs due to the manual labor and specialized attention required for prototypes, while mass production significantly reduces costs through economies of scale and automated processes. Material sourcing in mass production benefits from bulk purchasing discounts unavailable in sample making, further lowering overall expenses. Although sample making demands greater upfront investment, mass production maximizes cost efficiency when producing large quantities of garments.

Quality Control: Prototyping vs Bulk Manufacturing

Sample making emphasizes meticulous quality control through prototyping, allowing designers to identify and resolve defects early. Bulk manufacturing requires rigorous quality assurance systems to maintain consistency and minimize variations across large production volumes. Effective quality control strategies in both stages ensure durable, high-standard garments that meet design specifications and customer expectations.

Lead Time Comparison: Samples vs Large Orders

Sample making typically requires shorter lead times, often ranging from a few days to two weeks, depending on complexity and material availability. In contrast, mass production lead times extend significantly, usually from several weeks to months, due to the scale of orders, procurement processes, and quality assurance steps. Efficient communication and streamlined workflows help in reducing delays for both sample creation and large-scale manufacturing.

When to Choose Sample Making Over Mass Production

Sample making is ideal when designers need to evaluate fit, fabric, and construction details before committing to large-scale manufacturing. It offers flexibility for modifications, reducing costly errors in mass production. Opt for sample making when testing new concepts, assessing market viability, or customizing limited runs to ensure quality and precision.

Impact on Customization and Design Flexibility

Sample making allows for extensive design flexibility and high customization, enabling designers to test and refine intricate details before full-scale production. Mass production prioritizes efficiency and consistency, often limiting customization options due to standardized processes and fixed patterns. The balance between sample making and mass production significantly affects a brand's ability to innovate and cater to niche markets with unique design specifications.

Sample making vs Mass production Infographic

bizdif.com

bizdif.com