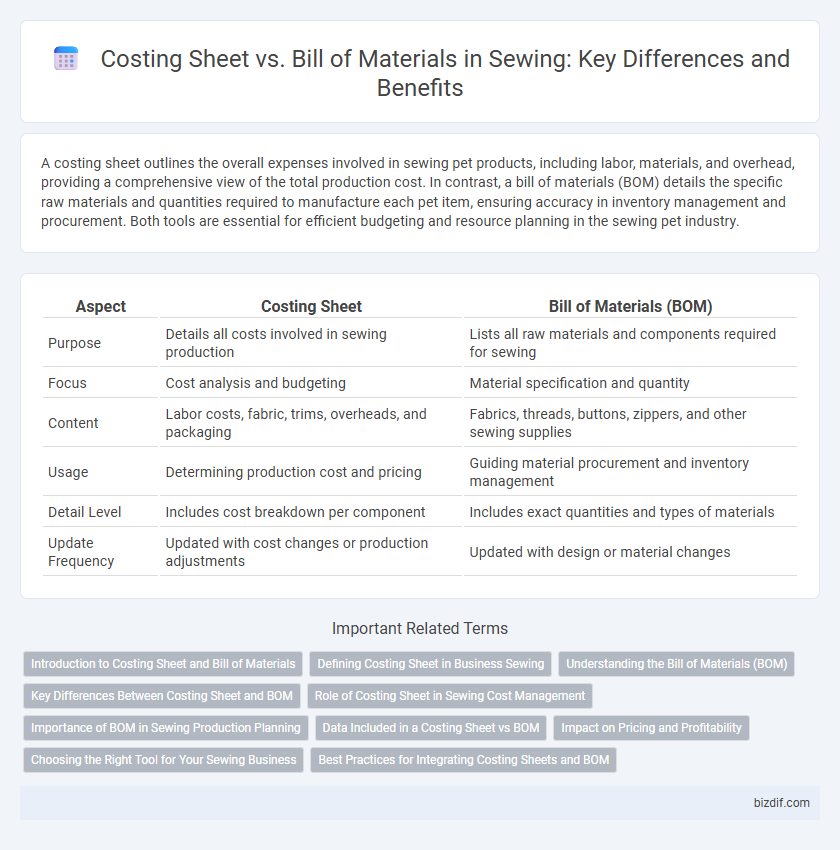

A costing sheet outlines the overall expenses involved in sewing pet products, including labor, materials, and overhead, providing a comprehensive view of the total production cost. In contrast, a bill of materials (BOM) details the specific raw materials and quantities required to manufacture each pet item, ensuring accuracy in inventory management and procurement. Both tools are essential for efficient budgeting and resource planning in the sewing pet industry.

Table of Comparison

| Aspect | Costing Sheet | Bill of Materials (BOM) |

|---|---|---|

| Purpose | Details all costs involved in sewing production | Lists all raw materials and components required for sewing |

| Focus | Cost analysis and budgeting | Material specification and quantity |

| Content | Labor costs, fabric, trims, overheads, and packaging | Fabrics, threads, buttons, zippers, and other sewing supplies |

| Usage | Determining production cost and pricing | Guiding material procurement and inventory management |

| Detail Level | Includes cost breakdown per component | Includes exact quantities and types of materials |

| Update Frequency | Updated with cost changes or production adjustments | Updated with design or material changes |

Introduction to Costing Sheet and Bill of Materials

A Costing Sheet itemizes all expenses involved in garment production, including fabric, trims, labor, and overheads, to determine the total cost per unit for accurate pricing and budgeting. A Bill of Materials (BOM) lists the raw materials and components required for sewing each garment, detailing quantities and specifications essential for inventory management and production planning. Understanding both tools is crucial for optimizing manufacturing efficiency and maintaining cost control in the sewing industry.

Defining Costing Sheet in Business Sewing

A costing sheet in business sewing is a detailed document that outlines all expenses involved in producing a garment, including fabric, labor, trims, and overhead costs. It serves as a crucial tool for pricing products accurately and managing production budgets effectively. By breaking down each cost element, the costing sheet helps manufacturers optimize resource allocation and maintain profitability.

Understanding the Bill of Materials (BOM)

The Bill of Materials (BOM) is a detailed list of all raw materials, components, and quantities required to complete a sewing project, essential for accurate production planning and cost estimation. Unlike the costing sheet which primarily outlines financial expenses, the BOM provides a comprehensive breakdown of physical materials, helping manufacturers track inventory and optimize resource allocation. Understanding the BOM in sewing ensures precise material usage, reduces wastage, and supports effective communication between design, production, and procurement teams.

Key Differences Between Costing Sheet and BOM

A Costing Sheet details the overall expenses involved in producing a garment, including labor, overhead, and material costs, while a Bill of Materials (BOM) lists all raw materials and components required for assembly. The Costing Sheet focuses on financial analysis for pricing and budgeting, whereas the BOM emphasizes inventory control and production planning. Understanding these distinctions is crucial for accurate cost management and efficient workflow in garment manufacturing.

Role of Costing Sheet in Sewing Cost Management

The costing sheet in sewing cost management serves as a detailed financial blueprint, outlining all direct and indirect expenses associated with garment production including labor, materials, and overheads. It enables accurate estimation and control of production costs by providing a comprehensive breakdown of every cost component, facilitating budget adherence and pricing strategies. Effective use of the costing sheet ensures optimized resource allocation, minimizes wastage, and enhances overall profitability in sewing operations.

Importance of BOM in Sewing Production Planning

The Bill of Materials (BOM) is crucial in sewing production planning because it provides a detailed list of all materials, components, and quantities required for garment manufacturing, ensuring accurate inventory management and minimizing material wastage. Unlike the Costing Sheet, which focuses primarily on financial estimates, the BOM directly impacts production efficiency by streamlining procurement and assembly processes. Precise BOM data helps in forecasting material needs, scheduling production timelines, and maintaining quality control throughout the sewing process.

Data Included in a Costing Sheet vs BOM

A Costing Sheet in sewing includes detailed financial data such as material costs, labor expenses, overheads, and profit margins, providing a comprehensive budget for garment production. The Bill of Materials (BOM) lists all raw materials, components, and quantities needed for manufacturing, focusing on physical inputs rather than cost details. While the Costing Sheet emphasizes financial metrics, the BOM serves as an inventory and production guide essential for sourcing and planning.

Impact on Pricing and Profitability

A costing sheet outlines the total expenses involved in garment production, including labor, materials, and overheads, directly influencing the final pricing strategy. The bill of materials (BOM) provides a detailed list of all components required for sewing, essential for accurate material cost estimation and inventory management. Precise integration of costing sheets with BOM ensures optimized pricing, improved profit margins, and effective cost control in apparel manufacturing.

Choosing the Right Tool for Your Sewing Business

A Costing Sheet provides a detailed breakdown of all expenses involved in producing a garment, including labor, materials, and overhead, crucial for pricing and profitability analysis in sewing businesses. A Bill of Materials (BOM) lists all raw materials, components, and quantities required to manufacture a product, essential for inventory management and production planning. Selecting the right tool depends on your business needs: use a Costing Sheet to control costs and ensure profitability, while a BOM is vital for efficient material sourcing and workflow organization.

Best Practices for Integrating Costing Sheets and BOM

Effective integration of costing sheets and bills of materials (BOM) ensures accurate budgeting and inventory control in sewing projects. Use detailed BOMs to list every fabric and accessory with unit costs directly feeding into dynamic costing sheets that update total expenses automatically. Regularly reviewing and synchronizing these documents minimizes errors, optimizes material usage, and enhances profitability tracking in garment production.

Costing Sheet vs Bill of Materials Infographic

bizdif.com

bizdif.com