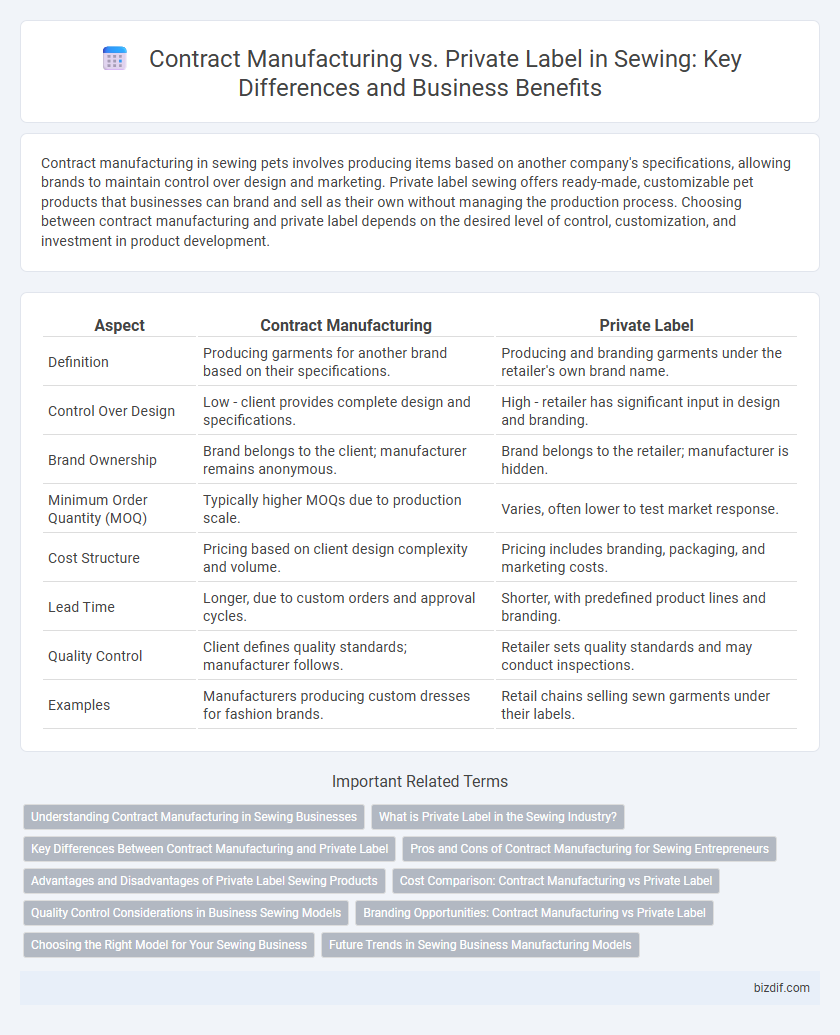

Contract manufacturing in sewing pets involves producing items based on another company's specifications, allowing brands to maintain control over design and marketing. Private label sewing offers ready-made, customizable pet products that businesses can brand and sell as their own without managing the production process. Choosing between contract manufacturing and private label depends on the desired level of control, customization, and investment in product development.

Table of Comparison

| Aspect | Contract Manufacturing | Private Label |

|---|---|---|

| Definition | Producing garments for another brand based on their specifications. | Producing and branding garments under the retailer's own brand name. |

| Control Over Design | Low - client provides complete design and specifications. | High - retailer has significant input in design and branding. |

| Brand Ownership | Brand belongs to the client; manufacturer remains anonymous. | Brand belongs to the retailer; manufacturer is hidden. |

| Minimum Order Quantity (MOQ) | Typically higher MOQs due to production scale. | Varies, often lower to test market response. |

| Cost Structure | Pricing based on client design complexity and volume. | Pricing includes branding, packaging, and marketing costs. |

| Lead Time | Longer, due to custom orders and approval cycles. | Shorter, with predefined product lines and branding. |

| Quality Control | Client defines quality standards; manufacturer follows. | Retailer sets quality standards and may conduct inspections. |

| Examples | Manufacturers producing custom dresses for fashion brands. | Retail chains selling sewn garments under their labels. |

Understanding Contract Manufacturing in Sewing Businesses

Contract manufacturing in sewing businesses involves outsourcing production to a specialized manufacturer who produces garments based on the client's design specifications and quality standards. This model reduces overhead costs and allows brands to focus on marketing, sales, and product development while leveraging the technical expertise and scalable capacity of the contract manufacturer. Understanding contract manufacturing enables sewing businesses to optimize supply chain efficiency, maintain consistent product quality, and accelerate time-to-market for apparel collections.

What is Private Label in the Sewing Industry?

Private label in the sewing industry refers to products manufactured by one company and sold under another company's brand name, allowing retailers to offer unique designs without owning production facilities. This model enables businesses to customize fabric, design, and quality specifications to match their brand identity while leveraging the expertise of established manufacturers. Private labeling enhances market differentiation and brand loyalty by providing exclusive apparel or textile products tailored to specific customer demographics.

Key Differences Between Contract Manufacturing and Private Label

Contract manufacturing involves outsourcing production to a specialized company that manufactures products based on the client's detailed specifications, while private label refers to products made by a manufacturer and sold under a retailer's brand name. The key differences lie in control over product design and branding; contract manufacturing offers greater customization and intellectual property ownership, whereas private label typically provides quicker market entry with pre-designed products. Pricing models also differ, with contract manufacturing often requiring higher minimum order quantities and upfront investment compared to private labeling's lower risk and flexibility.

Pros and Cons of Contract Manufacturing for Sewing Entrepreneurs

Contract manufacturing in sewing offers entrepreneurs access to skilled labor, advanced machinery, and reduced upfront costs, enabling rapid scaling without investing in production facilities. However, reliance on third-party manufacturers can lead to less control over quality, potential delays, and intellectual property risks. Entrepreneurs must balance cost savings and efficiency against the need for stringent quality oversight and brand integrity.

Advantages and Disadvantages of Private Label Sewing Products

Private label sewing products offer businesses greater control over design, quality, and branding, enabling unique market positioning and increased profit margins. However, they require significant upfront investment, meticulous quality management, and longer lead times compared to contract manufacturing. The risk of inventory obsolescence and the need for robust marketing strategies often challenge private label ventures in competitive sewing markets.

Cost Comparison: Contract Manufacturing vs Private Label

Contract manufacturing often involves lower upfront costs due to shared production facilities and bulk material sourcing, making it cost-effective for scaling operations without heavy investment. Private label manufacturing typically requires higher initial expenses for design customization, branding, and smaller order quantities, increasing per-unit costs. Evaluating long-term cost implications, contract manufacturing offers economies of scale, while private label provides brand control with potential higher marketing and supply chain expenses.

Quality Control Considerations in Business Sewing Models

Contract manufacturing in sewing offers rigorous quality control through established production protocols and regular inspections, ensuring consistency across large volumes. Private label models require businesses to implement their own quality assurance measures, often involving detailed fabric testing and product sampling to maintain brand standards. Both approaches demand strict oversight, but contract manufacturing leverages the manufacturer's expertise while private label prioritizes direct brand involvement in quality management.

Branding Opportunities: Contract Manufacturing vs Private Label

Contract manufacturing allows brands to maintain control over product design and branding elements, providing opportunities to enhance brand identity through customized sewing techniques and materials. Private label manufacturing offers businesses the ability to quickly launch products under their own brand name without investing in production facilities, leveraging existing manufacturer capabilities for consistent quality. Both models impact branding strategies, with contract manufacturing favoring bespoke brand differentiation and private label enabling faster market entry under a unified brand presence.

Choosing the Right Model for Your Sewing Business

Contract manufacturing offers sewing businesses the advantage of outsourcing production to specialized factories, ensuring high-quality output with reduced overhead costs. Private label allows for greater brand control and customization, giving businesses the ability to create unique sewing products that reflect their identity. Selecting the right model depends on factors such as production scale, budget, quality requirements, and brand strategy to optimize growth and profitability.

Future Trends in Sewing Business Manufacturing Models

Contract manufacturing in the sewing industry increasingly leverages advanced automation and AI-driven production techniques to enhance scalability and reduce costs, positioning itself as a flexible solution for rapid market demands. Private label manufacturing focuses on brand differentiation and quality control, integrating sustainable materials and ethical labor practices to meet growing consumer expectations. Hybrid models combining contract manufacturing efficiency with private label customization are emerging as a dominant trend, driving innovation and competitive advantage in the future sewing business landscape.

Contract Manufacturing vs Private Label Infographic

bizdif.com

bizdif.com