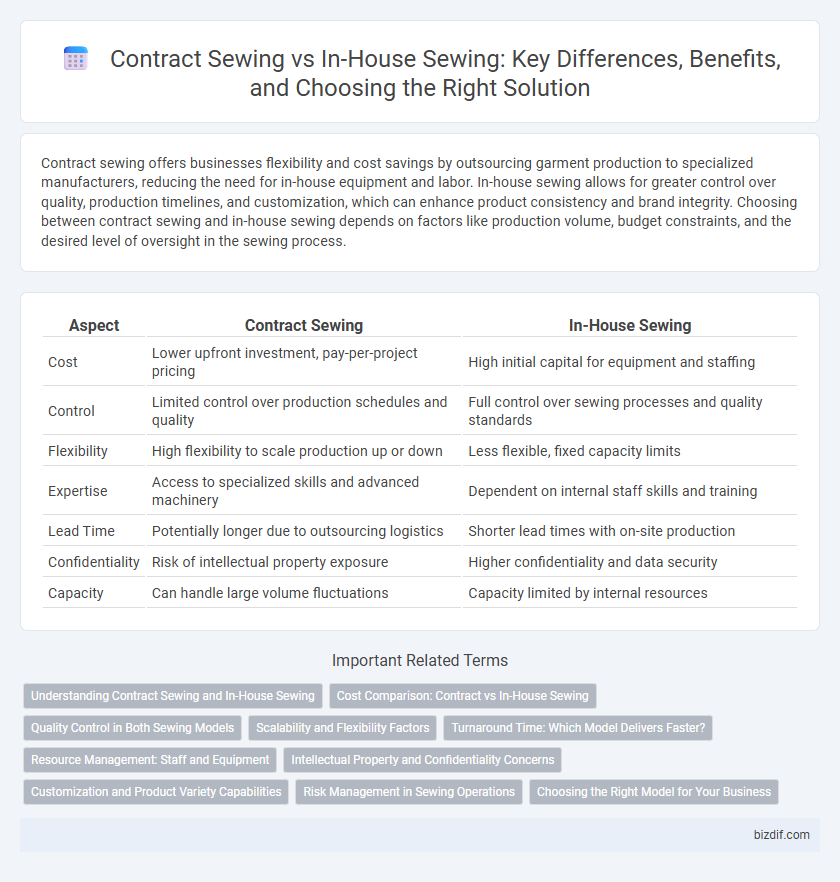

Contract sewing offers businesses flexibility and cost savings by outsourcing garment production to specialized manufacturers, reducing the need for in-house equipment and labor. In-house sewing allows for greater control over quality, production timelines, and customization, which can enhance product consistency and brand integrity. Choosing between contract sewing and in-house sewing depends on factors like production volume, budget constraints, and the desired level of oversight in the sewing process.

Table of Comparison

| Aspect | Contract Sewing | In-House Sewing |

|---|---|---|

| Cost | Lower upfront investment, pay-per-project pricing | High initial capital for equipment and staffing |

| Control | Limited control over production schedules and quality | Full control over sewing processes and quality standards |

| Flexibility | High flexibility to scale production up or down | Less flexible, fixed capacity limits |

| Expertise | Access to specialized skills and advanced machinery | Dependent on internal staff skills and training |

| Lead Time | Potentially longer due to outsourcing logistics | Shorter lead times with on-site production |

| Confidentiality | Risk of intellectual property exposure | Higher confidentiality and data security |

| Capacity | Can handle large volume fluctuations | Capacity limited by internal resources |

Understanding Contract Sewing and In-House Sewing

Contract sewing involves outsourcing garment production to specialized manufacturers, allowing businesses to leverage external expertise and reduce overhead costs. In-house sewing entails maintaining a dedicated production team within the company, providing greater control over quality, customization, and turnaround times. Selecting between contract and in-house sewing depends on factors such as production volume, budget constraints, and desired flexibility in design and delivery.

Cost Comparison: Contract vs In-House Sewing

Contract sewing often reduces overhead expenses by eliminating costs related to equipment maintenance, labor benefits, and facility management, making it a cost-effective option for businesses with fluctuating production volumes. In-house sewing requires significant capital investment in machinery, skilled labor salaries, and ongoing operational costs but allows greater control over quality and turnaround times. Evaluating cost per unit, contract sewing can provide savings for lower volumes, while in-house sewing may become more economical for large-scale, consistent manufacturing needs.

Quality Control in Both Sewing Models

Contract sewing often involves third-party manufacturers, making consistent quality control challenging due to varying standards and limited direct oversight. In-house sewing allows for tighter quality control through direct supervision, standardized protocols, and immediate adjustments during production. Both models require rigorous quality assurance systems, but in-house sewing generally ensures a higher level of consistency and faster defect resolution.

Scalability and Flexibility Factors

Contract sewing offers greater scalability by allowing businesses to quickly adjust production volumes without investing in additional machinery or labor, making it ideal for fluctuating demand. In-house sewing provides more control and customization but often limits flexibility due to fixed capacity and higher overhead costs. Choosing between contract and in-house sewing depends on the need for rapid scalability versus direct management of quality and workflow.

Turnaround Time: Which Model Delivers Faster?

Contract sewing typically offers faster turnaround times due to specialized workflows and scalable labor resources, making it ideal for large or time-sensitive orders. In-house sewing may experience slower production speeds as it often balances multiple tasks with limited staff and equipment. Businesses prioritizing rapid order fulfillment often prefer contract sewing for its efficiency and ability to meet tight deadlines.

Resource Management: Staff and Equipment

Contract sewing allows companies to optimize resource management by outsourcing labor and equipment needs, reducing overhead costs and minimizing investment in specialized machinery. In-house sewing requires dedicated staff and continuous maintenance of sewing machines, which can lead to higher fixed costs but offers greater control over production quality and scheduling. Efficient allocation of skilled personnel and advanced sewing equipment is critical to balancing cost-effectiveness and operational flexibility in both contract and in-house sewing setups.

Intellectual Property and Confidentiality Concerns

Contract sewing involves outsourcing garment production to external manufacturers, raising significant intellectual property (IP) and confidentiality risks due to potential exposure of proprietary designs and processes. In-house sewing allows companies to maintain tighter control over sensitive information and reduce the likelihood of IP theft or unauthorized sharing since all operations occur within a secured environment. Companies prioritizing IP protection often prefer in-house production to safeguard trade secrets and maintain competitive advantage in the fashion industry.

Customization and Product Variety Capabilities

Contract sewing offers extensive customization and a broad product variety by leveraging specialized expertise and advanced equipment, enabling manufacturers to efficiently scale diverse product lines. In-house sewing provides tighter control over customization details and consistency, but may face limitations in handling varied product types due to resource constraints. Choosing between contract and in-house sewing impacts the ability to manage complex designs and adapt swiftly to fluctuating market demands.

Risk Management in Sewing Operations

Contract sewing reduces capital investment and allows scalability but increases risks related to quality control, intellectual property, and supply chain disruptions. In-house sewing provides greater oversight, direct quality assurance, and tighter security of proprietary designs, but demands higher fixed costs and resource management. Effective risk management in sewing operations involves balancing cost, control, and flexibility to align with production goals and mitigate operational vulnerabilities.

Choosing the Right Model for Your Business

Contract sewing offers scalability and reduced overhead by outsourcing production to specialized manufacturers, ideal for businesses with fluctuating demand or limited workshop space. In-house sewing provides greater control over quality, customization, and turnaround times, suitable for brands prioritizing craftsmanship and direct oversight. Evaluating factors such as production volume, budget constraints, and quality expectations helps determine the optimal sewing model for your business success.

Contract sewing vs In-house sewing Infographic

bizdif.com

bizdif.com