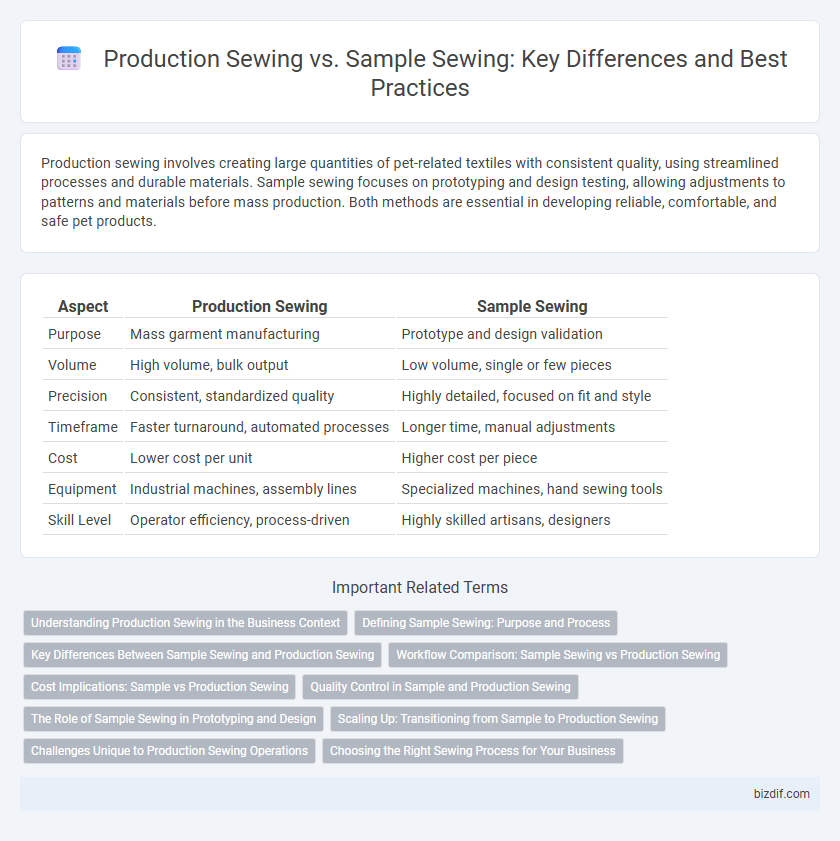

Production sewing involves creating large quantities of pet-related textiles with consistent quality, using streamlined processes and durable materials. Sample sewing focuses on prototyping and design testing, allowing adjustments to patterns and materials before mass production. Both methods are essential in developing reliable, comfortable, and safe pet products.

Table of Comparison

| Aspect | Production Sewing | Sample Sewing |

|---|---|---|

| Purpose | Mass garment manufacturing | Prototype and design validation |

| Volume | High volume, bulk output | Low volume, single or few pieces |

| Precision | Consistent, standardized quality | Highly detailed, focused on fit and style |

| Timeframe | Faster turnaround, automated processes | Longer time, manual adjustments |

| Cost | Lower cost per unit | Higher cost per piece |

| Equipment | Industrial machines, assembly lines | Specialized machines, hand sewing tools |

| Skill Level | Operator efficiency, process-driven | Highly skilled artisans, designers |

Understanding Production Sewing in the Business Context

Production sewing involves the large-scale fabrication of garments or textile products following finalized patterns and specifications, ensuring consistency and efficiency in meeting market demand. This process requires automated machinery and skilled operators to maintain high output quality and adherence to strict timelines. Understanding production sewing is critical for businesses aiming to optimize manufacturing costs, streamline supply chains, and scale operations effectively.

Defining Sample Sewing: Purpose and Process

Sample sewing involves creating prototype garments to evaluate design, fit, and fabric before mass production begins. This process allows designers and manufacturers to identify and resolve potential issues, ensuring the final product meets quality standards. Unlike production sewing, which focuses on large-scale garment assembly, sample sewing emphasizes precision and detail to perfect the garment's specifications.

Key Differences Between Sample Sewing and Production Sewing

Sample sewing involves creating one or a few prototype garments to test design, fit, and materials before mass production. Production sewing focuses on manufacturing large quantities of garments efficiently while maintaining consistent quality and meeting deadlines. Key differences include the scale of output, precision in achieving uniformity, and workflow speed tailored to bulk manufacturing versus experimental adjustments in sample sewing.

Workflow Comparison: Sample Sewing vs Production Sewing

Sample sewing involves creating initial prototypes to test design concepts, focusing on precision and flexibility to accommodate changes, while production sewing prioritizes consistent repetition and efficiency to manufacture large quantities of garments with uniform quality. In sample sewing, the workflow includes detailed adjustments and multiple fittings, whereas production sewing streamlines processes with standardized patterns and assembly line techniques to maximize speed. The transition from sample to production sewing requires optimizing tools and techniques to maintain quality standards while scaling output.

Cost Implications: Sample vs Production Sewing

Production sewing typically incurs lower per-unit costs due to economies of scale, bulk material purchasing, and streamlined assembly processes, making it cost-effective for large orders. Sample sewing involves higher expenses per unit because it requires intricate attention to detail, frequent adjustments, and often uses smaller quantities of materials, resulting in increased labor and fabric costs. Understanding these cost implications helps businesses budget accurately and optimize production timelines between prototyping and full-scale manufacturing.

Quality Control in Sample and Production Sewing

Quality control in sample sewing emphasizes precision and adherence to design specifications, ensuring prototypes meet exact standards before mass production. Production sewing quality control focuses on consistency, speed, and defect reduction across large volumes to maintain uniform product quality. Rigorous inspections during sample sewing help identify design flaws early, while ongoing monitoring in production sewing prevents deviations and ensures reliability.

The Role of Sample Sewing in Prototyping and Design

Sample sewing plays a critical role in prototyping and design by allowing designers to create and test garment concepts before full-scale production. This process helps identify potential fit, construction, and material issues early, ensuring the final product meets quality standards. By refining prototypes through sample sewing, manufacturers can minimize costly errors and streamline production sewing operations.

Scaling Up: Transitioning from Sample to Production Sewing

Scaling up from sample sewing to production sewing requires adapting processes for higher volume output while maintaining consistent quality standards. Production sewing involves standardized workflows, specialized machinery, and trained operators to ensure efficiency and repeatability, contrasting with the experimental and detailed nature of sample sewing. Effective scaling demands robust quality control systems and supply chain coordination to handle increased material procurement and reduced lead times.

Challenges Unique to Production Sewing Operations

Production sewing faces challenges such as maintaining consistent quality across large volumes, managing tight deadlines, and optimizing machine uptime for maximum efficiency. Unlike sample sewing, production sewing requires stringent process standardization and workforce coordination to minimize defects and rework. Operational scalability and supply chain synchronization are critical factors in addressing the complexities of high-volume garment manufacturing.

Choosing the Right Sewing Process for Your Business

Production sewing focuses on large-scale garment manufacturing, ensuring consistent quality and efficiency for bulk orders, while sample sewing creates prototypes for design validation and fit testing. Evaluating your business needs, order volume, and timeline helps determine whether to invest in production sewing for mass output or sample sewing for precise, customizable initial samples. Selecting the optimal sewing process enhances product development cycles and supports scalable operations with cost-effective resource allocation.

Production Sewing vs Sample Sewing Infographic

bizdif.com

bizdif.com