Chain stitching creates a flexible seam ideal for stretch fabrics but may unravel easily, while lock stitching produces a strong, secure seam that resists unraveling and is perfect for durable pet accessories. Pet collars and clothing benefit from lock stitching's durability, ensuring safety and longevity under active use. Chain stitching suits lightweight pet apparel that requires elasticity and comfort without compromising basic strength.

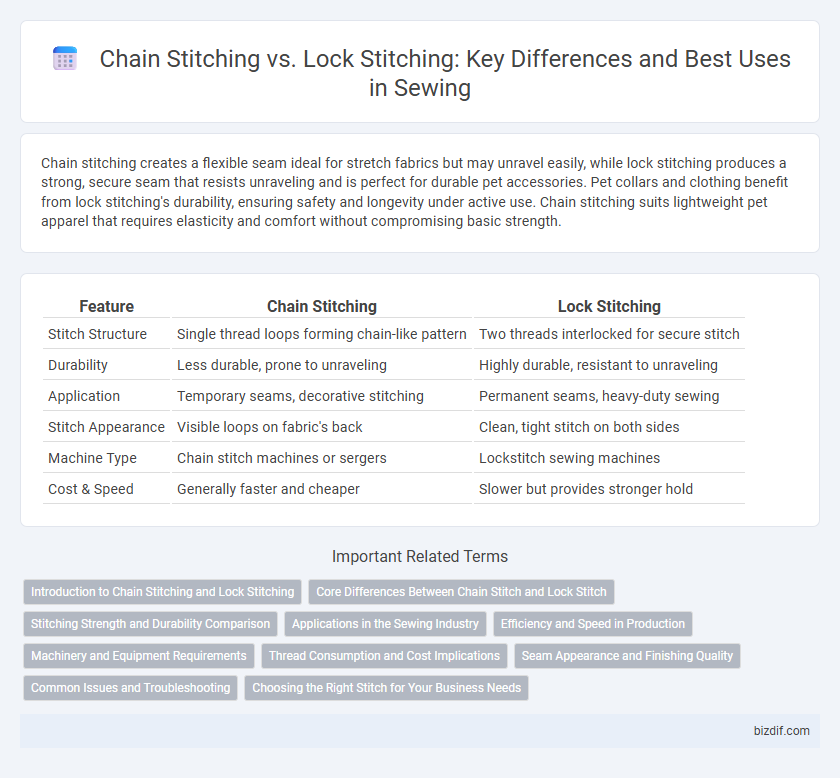

Table of Comparison

| Feature | Chain Stitching | Lock Stitching |

|---|---|---|

| Stitch Structure | Single thread loops forming chain-like pattern | Two threads interlocked for secure stitch |

| Durability | Less durable, prone to unraveling | Highly durable, resistant to unraveling |

| Application | Temporary seams, decorative stitching | Permanent seams, heavy-duty sewing |

| Stitch Appearance | Visible loops on fabric's back | Clean, tight stitch on both sides |

| Machine Type | Chain stitch machines or sergers | Lockstitch sewing machines |

| Cost & Speed | Generally faster and cheaper | Slower but provides stronger hold |

Introduction to Chain Stitching and Lock Stitching

Chain stitching forms a series of looped stitches resembling chain links, providing flexibility and decorative appeal in sewing. Lock stitching uses two threads interlocked between fabric layers, offering strong, durable seams resistant to unraveling. Understanding the structural differences between chain stitching and lock stitching helps determine their suitability for various textile applications and garment construction.

Core Differences Between Chain Stitch and Lock Stitch

Chain stitching forms a series of looped stitches using only one thread, making it faster and more elastic but less durable than lock stitching. Lock stitching utilizes two threads, interlocking on the fabric's underside, creating a strong, secure seam ideal for heavy-duty projects. The main difference lies in durability and elasticity, with chain stitches offering flexibility and lock stitches providing superior strength and resistance to unraveling.

Stitching Strength and Durability Comparison

Chain stitching, characterized by its looped thread structure, offers flexibility but generally provides lower tensile strength compared to lock stitching. Lock stitching creates interlocking threads that form a tighter, more secure seam, significantly enhancing durability and resistance to seam failure under tension. For heavy-duty or high-stress fabric applications, lock stitching is preferred due to its superior strength and long-lasting seam integrity.

Applications in the Sewing Industry

Chain stitching is commonly used in garment manufacturing for its elasticity and cost-effectiveness, ideal for sewing stretchy fabrics and temporary stitching. Lock stitching provides strong, durable seams suitable for high-stress areas in upholstery, denim, and heavy-duty workwear. The sewing industry favors lock stitching for final seams due to its resistance to unraveling, while chain stitching is preferred during preliminary assembly and decorative finishes.

Efficiency and Speed in Production

Chain stitching offers greater speed and efficiency in production due to its simpler mechanism, enabling faster sewing cycles and quicker fabric handling. However, lock stitching provides superior stitch durability and resistance to unraveling, which may reduce rework and increase overall production efficiency despite slower stitching speeds. Balancing speed with stitch strength is critical for optimizing production workflow in garment manufacturing.

Machinery and Equipment Requirements

Chain stitching machines require fewer components and simpler mechanisms, making them more cost-effective and easier to maintain compared to lock stitching machines. Lock stitch machines utilize two threads and involve a more complex bobbin system, demanding precise tension control and higher-quality equipment for consistent stitch formation. Industrial applications favor lock stitch machinery for durability and professional finish, while chain stitch equipment suits faster production with economical setups.

Thread Consumption and Cost Implications

Chain stitching consumes more thread compared to lock stitching due to its looped stitch design, which requires extra thread length for each stitch. This increased thread consumption directly raises material costs, making chain stitching more expensive in bulk production. However, lock stitching's interlocking threads result in lower thread usage and reduced costs, offering a more economical option for high-volume sewing tasks.

Seam Appearance and Finishing Quality

Chain stitching produces a more flexible seam with visible loops on the underside, often giving a decorative and textured appearance but less durability under stress. Lock stitching creates a tighter, cleaner seam with interlocked threads that lie flat, resulting in a smooth finish and higher strength for professional-quality garments. The choice impacts seam appearance and finishing quality, with lock stitching preferred for polished, durable seams while chain stitching suits lightweight or decorative applications.

Common Issues and Troubleshooting

Chain stitching often faces problems like unraveling and uneven tension due to its looped structure, making it less durable for heavy fabrics. Lock stitching, known for its interlocking threads, commonly encounters thread breakage and skipped stitches, usually caused by needle damage or incorrect thread tension. Troubleshooting involves adjusting tension settings, using appropriate needles, and regular machine maintenance to ensure consistent stitch quality and durability.

Choosing the Right Stitch for Your Business Needs

Chain stitching offers flexibility and rapid production, ideal for lightweight fabrics and temporary seams in apparel manufacturing. Lock stitching provides durable, secure seams suitable for heavy-duty fabrics and products requiring long-lasting strength, such as upholstery and denim. Selecting the right stitch depends on fabric type, product use, and desired seam durability to optimize efficiency and quality in your business.

Chain Stitching vs Lock Stitching Infographic

bizdif.com

bizdif.com