Chain stitch offers flexibility and a classic look, ideal for decorative seams or lightweight fabrics, while cover stitch provides durable, professional-quality finishes perfect for hemming and stretch fabrics. The cover stitch creates parallel rows of stitching on the top and a looper thread underneath, ensuring strong, stretchy seams resistant to wear. Choosing between chain stitch and cover stitch depends on fabric type and the desired balance between aesthetic and durability in sewing pet garments.

Table of Comparison

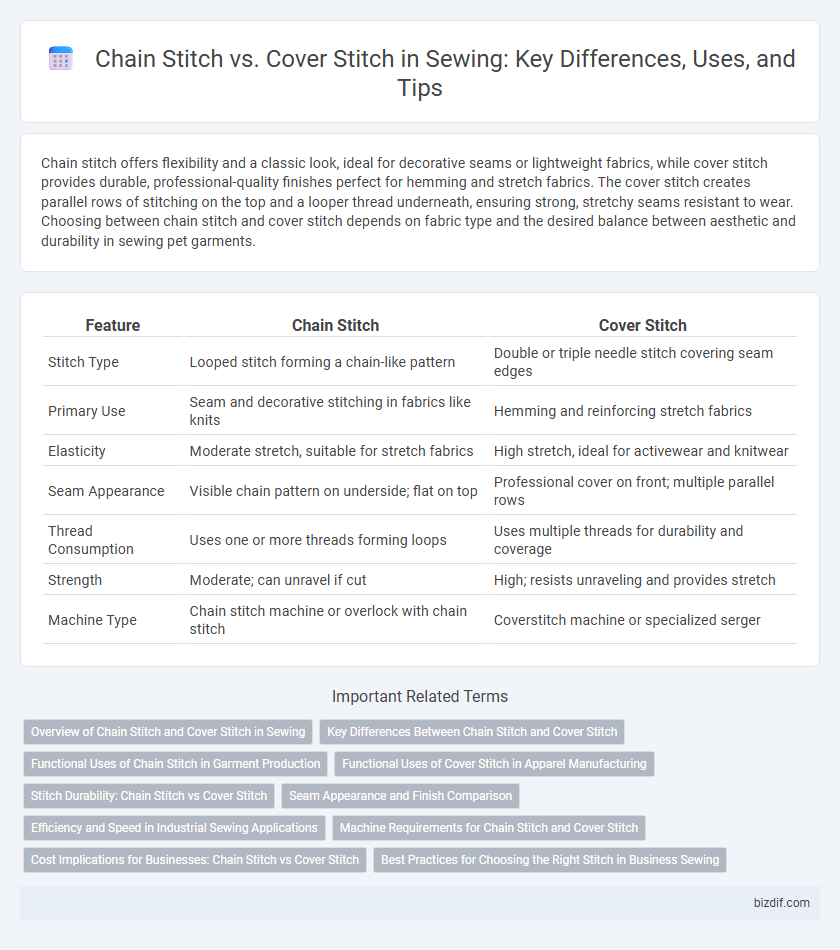

| Feature | Chain Stitch | Cover Stitch |

|---|---|---|

| Stitch Type | Looped stitch forming a chain-like pattern | Double or triple needle stitch covering seam edges |

| Primary Use | Seam and decorative stitching in fabrics like knits | Hemming and reinforcing stretch fabrics |

| Elasticity | Moderate stretch, suitable for stretch fabrics | High stretch, ideal for activewear and knitwear |

| Seam Appearance | Visible chain pattern on underside; flat on top | Professional cover on front; multiple parallel rows |

| Thread Consumption | Uses one or more threads forming loops | Uses multiple threads for durability and coverage |

| Strength | Moderate; can unravel if cut | High; resists unraveling and provides stretch |

| Machine Type | Chain stitch machine or overlock with chain stitch | Coverstitch machine or specialized serger |

Overview of Chain Stitch and Cover Stitch in Sewing

Chain stitch creates a series of looped stitches that form a flexible and decorative seam, commonly used for embroidery and lightweight fabric seams. Cover stitch utilizes multiple needles and a looper to produce a strong, flat seam ideal for hemming knit fabrics and activewear. Both stitches enhance garment durability, but chain stitch offers ornamental appeal while cover stitch excels in stretch and reinforcement.

Key Differences Between Chain Stitch and Cover Stitch

Chain stitch creates a flexible seam with visible loops on the underside, commonly used for decorative stitching and gathers, while cover stitch forms professional-looking hems with parallel needle lines on the front and a serger-like cover on the back. Chain stitch machines typically use a single needle and looper, whereas cover stitch machines utilize multiple needles and loopers to provide stretch and durability. The cover stitch is preferred for knit garments due to its strength and ability to maintain fabric stretch, unlike the chain stitch which can unravel more easily.

Functional Uses of Chain Stitch in Garment Production

Chain stitch is widely used in garment production for creating flexible seams that allow for stretch, making it ideal for knitwear and activewear. Its ability to form strong yet easily removable seams facilitates garment alterations and temporary stitching during fitting. Additionally, chain stitch is employed for decorative topstitching, enhancing both the durability and aesthetic appeal of garments.

Functional Uses of Cover Stitch in Apparel Manufacturing

Cover stitch is primarily used in apparel manufacturing for hemming knit fabrics, providing stretchable and durable seams ideal for activewear and casual clothing. Unlike the chain stitch, cover stitch creates a professional finish on garment edges, preventing fraying while maintaining fabric elasticity. Its dual-needle construction reinforces hems and seams, enhancing garment longevity and wearer comfort in stretchy materials.

Stitch Durability: Chain Stitch vs Cover Stitch

Chain stitch offers moderate durability with flexibility, making it suitable for lightweight fabrics but prone to unraveling under stress. Cover stitch provides superior durability and stretch, commonly used in activewear and hems to ensure long-lasting seams that resist wear and tear. Industrial sewing machines favor cover stitch for its strength and ability to maintain seam integrity during frequent movement.

Seam Appearance and Finish Comparison

Chain stitch creates a distinctive, looped seam appearance commonly used for decorative topstitching but may lack the durability needed for high-stress areas. Cover stitch forms a smooth, flat seam with a professional finish, often found on hems and knitwear, providing superior stretch and strength. The cover stitch's dual needle and looper mechanism ensures a clean, polished look with enhanced seam stability compared to the chain stitch.

Efficiency and Speed in Industrial Sewing Applications

Chain stitch offers high speed and efficiency in industrial sewing due to its simple mechanism and minimal thread consumption, making it ideal for fast production lines. Cover stitch provides enhanced durability and stretch, but operates slightly slower because of its complex dual-needle setup, best suited for high-quality knitwear manufacturing. Manufacturers often balance the speed advantage of chain stitch with the strength and finish of cover stitch to optimize productivity and garment performance.

Machine Requirements for Chain Stitch and Cover Stitch

Chain stitch machines require a single needle with a looper mechanism to create interlocking loops on the fabric's underside, making them ideal for lightweight and stretch materials. Cover stitch machines are equipped with multiple needles and dual loopers, enabling the formation of parallel rows of stitches with a decorative cover stitch on the top and a serged finish on the bottom, suitable for hemming knit garments. Understanding these machine requirements helps optimize stitch selection for durability and fabric type in garment construction.

Cost Implications for Businesses: Chain Stitch vs Cover Stitch

Chain stitch machines typically have lower initial costs and require less maintenance, making them cost-effective for small-scale businesses or startups. Cover stitch machines involve higher upfront investment but offer enhanced durability and professional finishing, reducing long-term expenses related to garment quality and returns. Businesses must weigh the balance between immediate savings with chain stitch and the long-term value of cover stitch for cost-efficient production.

Best Practices for Choosing the Right Stitch in Business Sewing

Selecting the appropriate stitch for business sewing requires understanding the distinct functions of chain stitch and cover stitch. Chain stitch offers flexibility and ease of repair, making it suitable for lightweight fabrics and temporary seams, while cover stitch provides durability and professional finish, ideal for hemming knits and stretch fabrics in commercial garment production. Evaluating fabric type, garment purpose, and production efficiency ensures optimal stitch choice that balances quality and cost-effectiveness in manufacturing.

Chain stitch vs Cover stitch Infographic

bizdif.com

bizdif.com