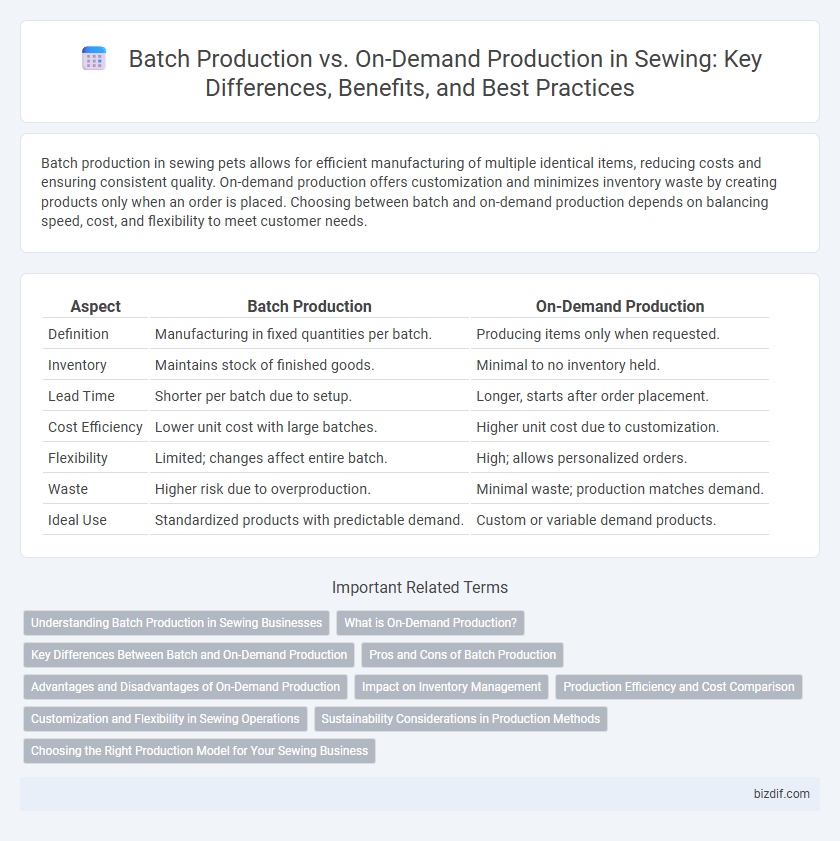

Batch production in sewing pets allows for efficient manufacturing of multiple identical items, reducing costs and ensuring consistent quality. On-demand production offers customization and minimizes inventory waste by creating products only when an order is placed. Choosing between batch and on-demand production depends on balancing speed, cost, and flexibility to meet customer needs.

Table of Comparison

| Aspect | Batch Production | On-Demand Production |

|---|---|---|

| Definition | Manufacturing in fixed quantities per batch. | Producing items only when requested. |

| Inventory | Maintains stock of finished goods. | Minimal to no inventory held. |

| Lead Time | Shorter per batch due to setup. | Longer, starts after order placement. |

| Cost Efficiency | Lower unit cost with large batches. | Higher unit cost due to customization. |

| Flexibility | Limited; changes affect entire batch. | High; allows personalized orders. |

| Waste | Higher risk due to overproduction. | Minimal waste; production matches demand. |

| Ideal Use | Standardized products with predictable demand. | Custom or variable demand products. |

Understanding Batch Production in Sewing Businesses

Batch production in sewing businesses involves creating a specified quantity of garments or textiles at one time, enabling efficient use of materials and labor. This method reduces setup times and manufacturing costs by grouping similar tasks, which is ideal for standardized designs and consistent quality control. Understanding batch production helps sewing businesses optimize inventory management and meet predictable customer demand with minimized wastage.

What is On-Demand Production?

On-demand production in sewing refers to creating garments or textile products only after receiving specific customer orders, minimizing inventory and reducing waste. This method allows for greater customization, faster response to market trends, and cost-efficiency by producing exactly what is needed. On-demand production leverages digital technologies such as automated cutting and digital printing to streamline workflows and meet precise consumer demands.

Key Differences Between Batch and On-Demand Production

Batch production involves manufacturing a set quantity of garments in groups, optimizing efficiency and reducing per-unit costs through economies of scale. On-demand production creates items individually based on customer orders, minimizing inventory and reducing waste but often resulting in higher production costs. Key differences include inventory management, lead time, cost efficiency, and flexibility in responding to market demand changes.

Pros and Cons of Batch Production

Batch production in sewing offers cost efficiency by producing large quantities of garments, reducing per-unit costs through economies of scale. It enables better inventory management and consistent quality due to standardized processes. However, batch production may lead to increased storage costs, risk of unsold inventory, and less flexibility to respond to market trends or custom orders quickly.

Advantages and Disadvantages of On-Demand Production

On-demand production in sewing minimizes inventory costs and reduces waste by producing garments only when orders are placed, enhancing cash flow and responsiveness to market trends. It allows for greater customization and quicker turnaround times, meeting specific customer demands more effectively. However, on-demand production can lead to higher per-unit costs and potential delays, as economies of scale are limited and production scheduling depends heavily on incoming orders.

Impact on Inventory Management

Batch production in sewing leads to larger inventory holdings due to mass manufacturing of garments, which increases storage costs and risk of unsold stock. On-demand production minimizes inventory by producing garments only after receiving customer orders, reducing excess stock and enhancing cash flow efficiency. Efficient inventory management in on-demand systems relies heavily on accurate demand forecasting and flexible supply chains to meet customer needs swiftly.

Production Efficiency and Cost Comparison

Batch production in sewing enhances production efficiency by allowing multiple garments to be constructed simultaneously, reducing setup time and machine idle periods, which lowers overall labor costs. On-demand production minimizes inventory expenses and waste by producing only the required quantity, but often incurs higher per-unit costs due to frequent changeovers and smaller run sizes. Cost comparison reveals batch production is more economical for large orders, whereas on-demand suits customized or limited runs with greater flexibility but at a premium.

Customization and Flexibility in Sewing Operations

Batch production in sewing allows for moderate customization while optimizing fabric use and reducing setup times, suitable for orders with consistent styles and sizes. On-demand production offers superior flexibility, enabling tailor-made garments that meet specific client preferences and size variations without excess inventory. This adaptability in on-demand sewing operations enhances customer satisfaction through personalized apparel and minimizes waste.

Sustainability Considerations in Production Methods

Batch production in sewing often results in excess fabric waste and unsold inventory, increasing environmental impact through resource inefficiency. On-demand production minimizes material usage and reduces waste by producing garments only when ordered, supporting sustainable resource management. Sustainable sewing practices prioritize on-demand methods to lower carbon footprints and promote circular fashion principles.

Choosing the Right Production Model for Your Sewing Business

Batch production in sewing offers efficiency and cost savings for larger orders by producing garments in groups, minimizing setup time and material waste. On-demand production suits custom or small orders, reducing inventory costs and allowing greater flexibility to meet specific customer preferences. Selecting the right sewing production model depends on order volume, lead time, and customer demand, ensuring optimal resource utilization and profitability.

Batch Production vs On-Demand Production Infographic

bizdif.com

bizdif.com