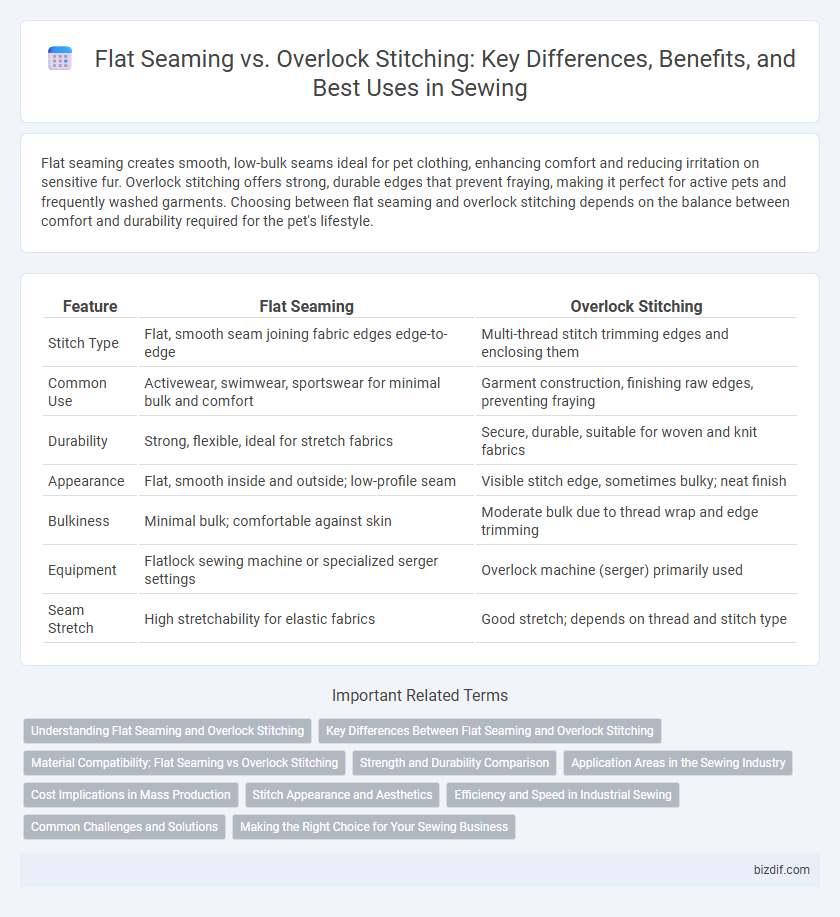

Flat seaming creates smooth, low-bulk seams ideal for pet clothing, enhancing comfort and reducing irritation on sensitive fur. Overlock stitching offers strong, durable edges that prevent fraying, making it perfect for active pets and frequently washed garments. Choosing between flat seaming and overlock stitching depends on the balance between comfort and durability required for the pet's lifestyle.

Table of Comparison

| Feature | Flat Seaming | Overlock Stitching |

|---|---|---|

| Stitch Type | Flat, smooth seam joining fabric edges edge-to-edge | Multi-thread stitch trimming edges and enclosing them |

| Common Use | Activewear, swimwear, sportswear for minimal bulk and comfort | Garment construction, finishing raw edges, preventing fraying |

| Durability | Strong, flexible, ideal for stretch fabrics | Secure, durable, suitable for woven and knit fabrics |

| Appearance | Flat, smooth inside and outside; low-profile seam | Visible stitch edge, sometimes bulky; neat finish |

| Bulkiness | Minimal bulk; comfortable against skin | Moderate bulk due to thread wrap and edge trimming |

| Equipment | Flatlock sewing machine or specialized serger settings | Overlock machine (serger) primarily used |

| Seam Stretch | High stretchability for elastic fabrics | Good stretch; depends on thread and stitch type |

Understanding Flat Seaming and Overlock Stitching

Flat seaming creates a smooth, low-profile join by aligning fabric edges edge-to-edge and stitching them together, minimizing bulk and enhancing comfort in activewear and knit garments. Overlock stitching trims excess fabric while encasing the raw edges with thread loops, preventing fraying and producing durable, flexible seams ideal for stretch fabrics. Both techniques improve garment durability but serve distinct functions based on fabric type and design requirements.

Key Differences Between Flat Seaming and Overlock Stitching

Flat seaming creates a smooth, flat join ideal for activewear and reducing chafing, using a double needle to overlap fabric edges without bulk. Overlock stitching trims the fabric edges while sewing, providing a secure, stretchy finish often used for seams in knit fabrics and garment construction. Key differences include the seam thickness, edge finishing, and the type of machines used, with flat seams emphasizing comfort and overlock ensuring durability.

Material Compatibility: Flat Seaming vs Overlock Stitching

Flat seaming works best with lightweight and stretch fabrics like knits and activewear, providing smooth, comfortable seams without bulk. Overlock stitching is more versatile, accommodating a wider range of materials including medium to heavyweight fabrics such as denim, canvas, and woven textiles, while offering strong, durable edge finishes. Choosing between flat seaming and overlock stitching depends on fabric thickness, stretchability, and the desired seam strength and appearance.

Strength and Durability Comparison

Flat seaming provides excellent strength by joining fabric layers edge-to-edge, reducing bulk and creating a smooth, sturdy finish ideal for activewear and swimwear. Overlock stitching secures raw edges and prevents fraying, offering high durability through multi-thread loops, but may add some bulk and less flexibility in certain stretch fabrics. For maximum seam reinforcement, flat seams excel in comfort and wear resistance, while overlock stitches deliver superior edge protection and elasticity in heavy-duty applications.

Application Areas in the Sewing Industry

Flat seaming is commonly applied in sportswear and activewear manufacturing due to its ability to create smooth, low-profile seams that reduce chafing during physical activity. Overlock stitching is extensively used in garment production for edging, hemming, and seaming knit fabrics, providing durability and stretch essential for casual and mass-produced clothing. Both techniques serve critical roles in apparel assembly, with flat seaming favored for comfort and overlock stitching preferred for finishing and reinforcement.

Cost Implications in Mass Production

Flat seaming offers lower equipment costs and minimal thread usage, making it cost-effective for mass production with lightweight fabrics. Overlock stitching, while requiring higher initial investment in specialized machines and more thread consumption, delivers faster production speeds and strong, stretchable seams suitable for knitwear. Evaluating these factors, manufacturers balance cost savings against production efficiency and product type when choosing between flat seaming and overlock stitching.

Stitch Appearance and Aesthetics

Flat seaming creates a smooth, nearly invisible join ideal for lightweight fabrics and athletic wear, enhancing comfort and minimal bulk. Overlock stitching produces a clean, professional edge with visible loops that prevent fraying but add texture and thickness. The choice between flat seaming and overlock stitching significantly affects garment aesthetics, influencing seam visibility and overall finish quality.

Efficiency and Speed in Industrial Sewing

Flat seaming offers streamlined fabric alignment that reduces bulk, enhancing cutting and assembly speed in industrial sewing. Overlock stitching excels in high-speed production by simultaneously trimming and seaming fabric edges, significantly increasing throughput. Both techniques improve efficiency, but overlock stitching provides superior speed for mass garment manufacturing.

Common Challenges and Solutions

Flat seaming often faces challenges such as fabric bulkiness and seam durability, which can be mitigated by precise stitch length adjustment and using stretch-compatible thread. Overlock stitching may encounter thread breakage and uneven tension, resolved through regular machine maintenance, appropriate needle selection, and proper threading techniques. Both methods require balancing fabric type and garment use to optimize seam strength and comfort.

Making the Right Choice for Your Sewing Business

Flat seaming offers a smooth, low-profile finish ideal for knitwear and activewear, reducing bulk and enhancing comfort, while overlock stitching provides strong, stretchy seam edges perfect for preventing fabric fraying in woven and knit fabrics. Choosing between flat seaming and overlock stitching depends on the fabric type, garment design, and desired durability, with flat seams favored for high-performance apparel and overlock stitches common in mass production for efficiency. Investing in the appropriate machinery like flatlock machines for seamless joins or overlock machines for versatile edge finishes optimizes production quality and workflow in your sewing business.

Flat Seaming vs Overlock Stitching Infographic

bizdif.com

bizdif.com