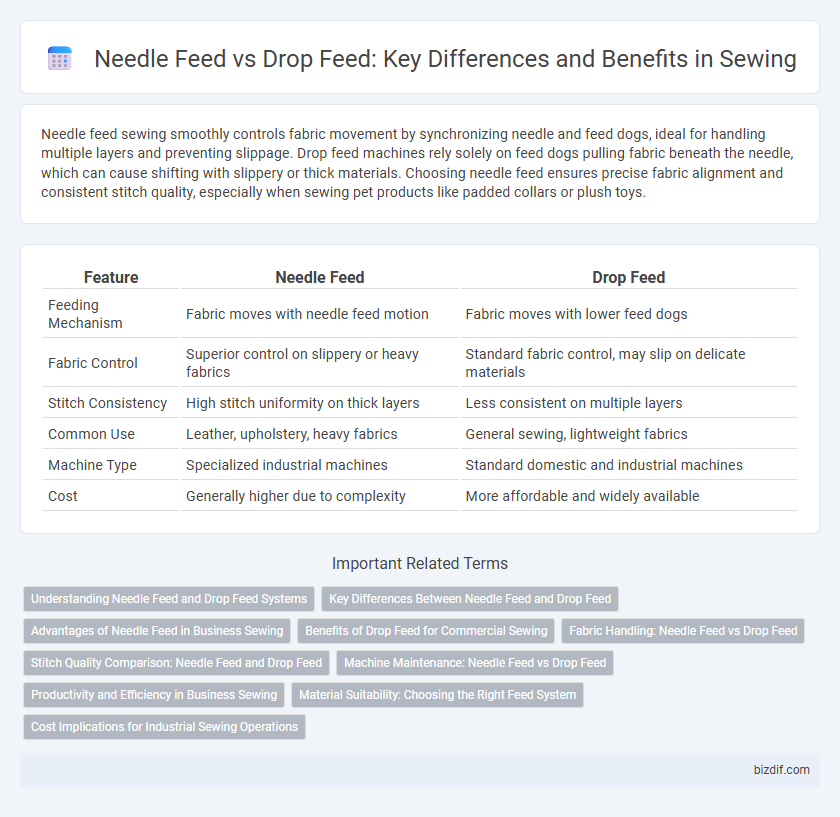

Needle feed sewing smoothly controls fabric movement by synchronizing needle and feed dogs, ideal for handling multiple layers and preventing slippage. Drop feed machines rely solely on feed dogs pulling fabric beneath the needle, which can cause shifting with slippery or thick materials. Choosing needle feed ensures precise fabric alignment and consistent stitch quality, especially when sewing pet products like padded collars or plush toys.

Table of Comparison

| Feature | Needle Feed | Drop Feed |

|---|---|---|

| Feeding Mechanism | Fabric moves with needle feed motion | Fabric moves with lower feed dogs |

| Fabric Control | Superior control on slippery or heavy fabrics | Standard fabric control, may slip on delicate materials |

| Stitch Consistency | High stitch uniformity on thick layers | Less consistent on multiple layers |

| Common Use | Leather, upholstery, heavy fabrics | General sewing, lightweight fabrics |

| Machine Type | Specialized industrial machines | Standard domestic and industrial machines |

| Cost | Generally higher due to complexity | More affordable and widely available |

Understanding Needle Feed and Drop Feed Systems

Needle feed systems synchronize needle movement with fabric feeding, providing precise control ideal for matched patterns and multiple layers, ensuring consistent stitch formation. Drop feed systems rely on feed dogs moving fabric beneath the needle, suitable for general sewing but less effective on slippery or thick materials due to potential fabric shifting. Understanding these mechanisms helps select the appropriate system, enhancing stitching accuracy and fabric handling.

Key Differences Between Needle Feed and Drop Feed

Needle feed sewing machines use the needle to move the fabric forward, providing better control and preventing fabric slippage, ideal for sewing multiple layers or slippery materials. Drop feed machines rely on feed dogs beneath the fabric to advance it, which can cause uneven feeding or shifting with difficult fabrics. The needle feed system ensures precise fabric handling and consistent stitch quality, whereas drop feed machines are generally simpler and more common but less effective for challenging sewing projects.

Advantages of Needle Feed in Business Sewing

Needle feed sewing machines offer superior fabric control by moving the material precisely with the needle, reducing slippage and ensuring consistent stitch quality on various fabric types. This enhanced feeding mechanism increases production efficiency and minimizes material waste, making it ideal for high-volume business sewing operations. Businesses benefit from improved accuracy in complex stitching patterns and reduced need for manual fabric adjustment, leading to higher productivity and product quality.

Benefits of Drop Feed for Commercial Sewing

Drop feed systems in commercial sewing machines provide consistent fabric control, reducing puckering and distortion, which enhances seam quality. The mechanism allows for smooth fabric movement suited for delicate or lightweight materials, making it ideal for varied textiles in mass production. This system also simplifies fabric handling, increasing efficiency and minimizing fabric damage during high-speed sewing operations.

Fabric Handling: Needle Feed vs Drop Feed

Needle feed systems provide superior fabric handling by synchronizing the needle motion with the feed dogs, ensuring precise and consistent fabric movement ideal for matching patterns and sewing multiple layers. Drop feed mechanisms rely solely on the feed dogs to move the fabric, which can cause shifting or uneven feeding, especially with slippery or delicate materials. For handling challenging fabrics like leather, vinyl, or stretch knits, needle feed offers better control and reduces fabric distortion compared to drop feed.

Stitch Quality Comparison: Needle Feed and Drop Feed

Needle feed sewing machines deliver precise fabric movement by synchronizing the needle and feed dog, resulting in consistent stitch quality especially on multiple layers or slippery fabrics. Drop feed machines rely solely on the feed dog to move the fabric, which can cause slight fabric shifting and lead to uneven stitch tension or puckering on delicate materials. Needle feed technology generally provides superior stitch accuracy and uniformity, making it ideal for high-quality garment production where stitch consistency is critical.

Machine Maintenance: Needle Feed vs Drop Feed

Needle feed sewing machines require more frequent maintenance to ensure the synchronized movement of the needle and fabric, preventing skipped stitches and fabric damage. Drop feed machines typically experience less mechanical wear, but regular cleaning and lubrication of the feed dogs and shuttle hook remain crucial to avoid fabric slippage and uneven feeding. Proper machine maintenance in both needle feed and drop feed systems prolongs equipment lifespan and maintains sewing accuracy, especially in industrial settings.

Productivity and Efficiency in Business Sewing

Needle feed machines synchronize fabric movement with the needle, resulting in consistent stitch quality and reduced fabric slippage, which enhances productivity by minimizing rework. Drop feed systems move fabric solely by the feed dogs, often causing material shifts and slower handling of heavy or layered fabrics, leading to decreased efficiency in business sewing. Selecting needle feed technology boosts production speed and ensures fabric precision, optimizing operational efficiency in commercial sewing environments.

Material Suitability: Choosing the Right Feed System

Needle feed systems excel in handling layered or slippery materials such as leather, vinyl, and multiple fabric layers by feeding the upper fabric smoothly without shifting. Drop feed mechanisms work best with lighter, woven fabrics and offer reliable feeding for single-layer sewing on cotton or polyester. Selecting the appropriate feed system enhances stitch consistency and fabric integrity, crucial for specialized materials in garment and upholstery production.

Cost Implications for Industrial Sewing Operations

Needle feed sewing machines generally come with higher upfront costs compared to drop feed models due to their advanced fabric handling mechanism that improves stitch quality on difficult materials. Operational expenses tend to be lower with needle feed machines since they reduce fabric slippage and defects, minimizing costly rework and material waste in high-volume production. Drop feed machines offer a more affordable initial investment but may increase long-term costs through higher maintenance requirements and lower stitch consistency on thick or slippery fabrics.

Needle Feed vs Drop Feed Infographic

bizdif.com

bizdif.com