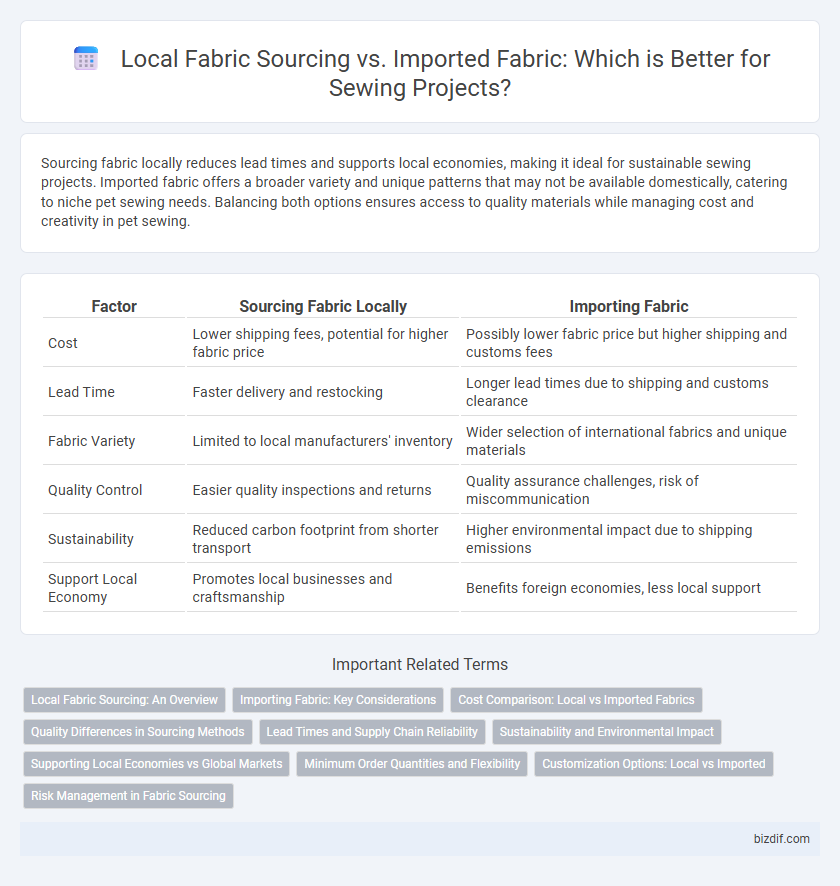

Sourcing fabric locally reduces lead times and supports local economies, making it ideal for sustainable sewing projects. Imported fabric offers a broader variety and unique patterns that may not be available domestically, catering to niche pet sewing needs. Balancing both options ensures access to quality materials while managing cost and creativity in pet sewing.

Table of Comparison

| Factor | Sourcing Fabric Locally | Importing Fabric |

|---|---|---|

| Cost | Lower shipping fees, potential for higher fabric price | Possibly lower fabric price but higher shipping and customs fees |

| Lead Time | Faster delivery and restocking | Longer lead times due to shipping and customs clearance |

| Fabric Variety | Limited to local manufacturers' inventory | Wider selection of international fabrics and unique materials |

| Quality Control | Easier quality inspections and returns | Quality assurance challenges, risk of miscommunication |

| Sustainability | Reduced carbon footprint from shorter transport | Higher environmental impact due to shipping emissions |

| Support Local Economy | Promotes local businesses and craftsmanship | Benefits foreign economies, less local support |

Local Fabric Sourcing: An Overview

Local fabric sourcing supports regional textile industries by reducing transportation costs and environmental impact. It enables faster turnaround times and easier quality control, ensuring fabrics meet specific design and durability requirements. Moreover, sourcing fabric locally often fosters stronger supplier relationships and promotes sustainable, ethical production practices within the community.

Importing Fabric: Key Considerations

Importing fabric requires careful evaluation of customs regulations, import duties, and shipping times to avoid delays and unexpected costs. Assessing fabric quality standards and certifications from international suppliers ensures product consistency and compliance with safety requirements. Establishing reliable supplier relationships and understanding currency fluctuations are crucial for maintaining a steady fabric supply and managing overall expenses.

Cost Comparison: Local vs Imported Fabrics

Local fabric sourcing often reduces transportation and import taxes, leading to lower overall costs and faster supply chain turnaround. Imported fabrics may offer unique designs and higher quality options but typically incur higher expenses due to shipping fees, customs duties, and longer delivery times. Comparing cost-effectiveness depends on the fabric type, quantity required, and the balance between price and design preferences for sewing projects.

Quality Differences in Sourcing Methods

Sourcing fabric locally often ensures higher quality control due to easier access to material inspection and direct communication with suppliers, leading to consistent and reliable textile standards. Imported fabrics may offer a broader variety and potentially lower prices but can suffer from quality inconsistencies caused by longer supply chains and less stringent oversight. Evaluating fabric quality differences critically impacts production outcomes, influencing garment durability, texture, and overall consumer satisfaction.

Lead Times and Supply Chain Reliability

Sourcing fabric locally significantly reduces lead times, allowing faster turnaround for sewing projects and minimizing production delays. Local suppliers typically offer more reliable supply chains with improved communication and fewer logistical disruptions compared to importing fabric. Importing fabric often involves longer shipping durations and risks of customs delays, which can hinder production schedules and increase overall project costs.

Sustainability and Environmental Impact

Sourcing fabric locally reduces carbon emissions associated with long-distance transportation and supports regional economies, enhancing sustainability in the sewing industry. Imported fabrics often have a larger environmental footprint due to extensive shipping and potential lack of transparency in production practices. Prioritizing local fabric sourcing minimizes waste and encourages the use of eco-friendly, regionally sourced materials that align with green manufacturing standards.

Supporting Local Economies vs Global Markets

Sourcing fabric locally strengthens local economies by creating jobs and supporting regional artisans, which fosters sustainable community growth and reduces carbon footprints through minimized transportation. Importing fabric expands access to diverse global markets and unique textile varieties, offering opportunities for competitive pricing and innovation. Balancing both approaches enhances fabric availability while promoting economic resilience on multiple scales.

Minimum Order Quantities and Flexibility

Sourcing fabric locally often offers lower minimum order quantities, enabling smaller production runs and greater flexibility for custom projects. Imported fabrics typically require larger minimum order quantities, which can limit agility and increase upfront costs for small businesses. Choosing local suppliers supports quick turnaround times and easier communication, enhancing responsiveness to design changes and inventory management.

Customization Options: Local vs Imported

Local fabric sourcing offers greater customization options with quicker turnaround times and direct collaboration with suppliers, enabling tailored designs and unique material blends. Imported fabrics provide access to diverse textures and rare materials not readily available domestically but often have longer lead times and limited customization flexibility. Balancing local and imported sourcing allows sewing businesses to optimize fabric variety and customization potential while managing production schedules effectively.

Risk Management in Fabric Sourcing

Sourcing fabric locally reduces risks associated with shipping delays, customs clearance, and fluctuating import tariffs, ensuring a more reliable supply chain. Local sourcing facilitates better quality control and faster response to market trends, minimizing the risk of receiving substandard materials. Importing fabric, while offering access to diverse textiles, carries higher risks of geopolitical disruptions, currency fluctuations, and increased lead times that can impact production schedules.

Sourcing fabric locally vs importing fabric Infographic

bizdif.com

bizdif.com