Chain stitch creates a flexible, decorative seam often used in embroidery but tends to unravel easily under stress, making it less durable for pet accessories. Lock stitch provides a strong, secure seam by interlocking threads, ensuring longevity and resistance to wear, ideal for pet collars and harnesses. Choosing lock stitch over chain stitch enhances the durability and safety of sewn items for pets.

Table of Comparison

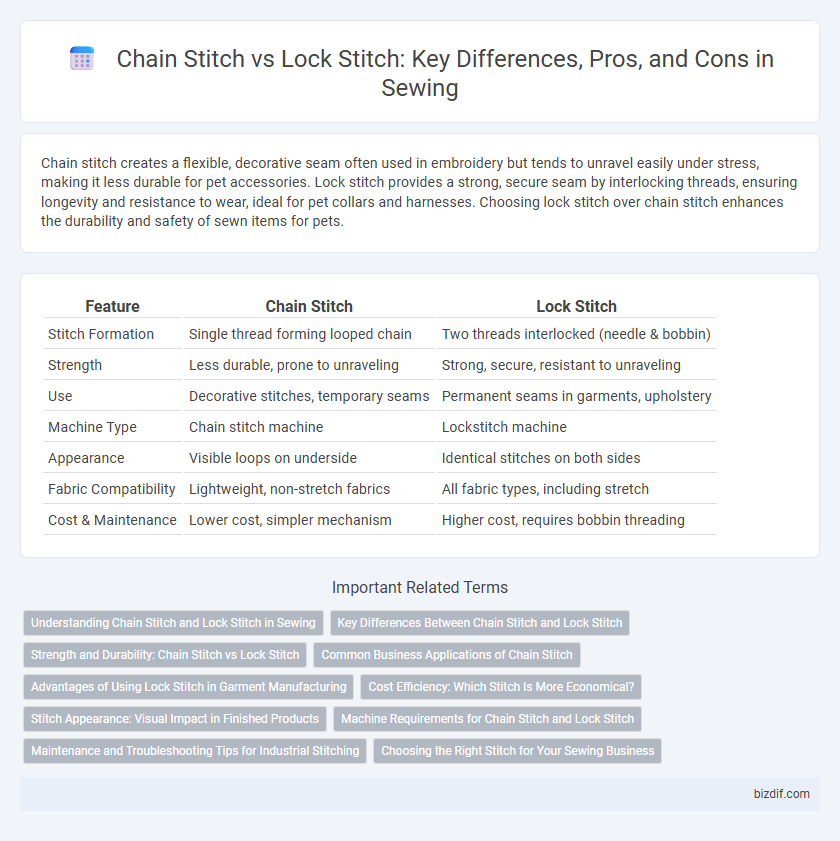

| Feature | Chain Stitch | Lock Stitch |

|---|---|---|

| Stitch Formation | Single thread forming looped chain | Two threads interlocked (needle & bobbin) |

| Strength | Less durable, prone to unraveling | Strong, secure, resistant to unraveling |

| Use | Decorative stitches, temporary seams | Permanent seams in garments, upholstery |

| Machine Type | Chain stitch machine | Lockstitch machine |

| Appearance | Visible loops on underside | Identical stitches on both sides |

| Fabric Compatibility | Lightweight, non-stretch fabrics | All fabric types, including stretch |

| Cost & Maintenance | Lower cost, simpler mechanism | Higher cost, requires bobbin threading |

Understanding Chain Stitch and Lock Stitch in Sewing

Chain stitch creates loops linked together in a single thread, offering flexibility but lower durability, ideal for temporary seams or embroidery. Lock stitch uses two threads interlocking between fabric layers, producing a strong and secure seam suitable for most garment constructions. Understanding the differences helps select the appropriate stitch for strength, elasticity, and application in sewing projects.

Key Differences Between Chain Stitch and Lock Stitch

Chain stitch forms loops interconnected in a single thread pattern, offering flexibility and decorative appeal, but it is less durable and prone to unraveling. Lock stitch uses two threads interlocked between fabric layers, providing stronger, more secure seams ideal for everyday sewing and heavy fabrics. Differences in stitch strength, appearance, and machine requirements distinguish chain stitch from lock stitch in practical sewing applications.

Strength and Durability: Chain Stitch vs Lock Stitch

Lock stitch offers superior strength and durability compared to chain stitch due to its interlocking threads that resist unraveling under tension. Chain stitch, while flexible and suitable for decorative purposes, tends to be weaker and more prone to unraveling, especially under stress or frequent wear. Industrial and garment manufacturing predominantly use lock stitch for seams requiring long-lasting durability and resistance to fabric strain.

Common Business Applications of Chain Stitch

Chain stitch is widely used in the production of denim, sportswear, and decorative embroidery due to its flexibility and distinctive appearance. This stitch excels in applications requiring stretchability and aesthetic appeal, such as branding logos and embellishments on garments. While lock stitch offers superior strength for seams, chain stitch remains preferred in industries prioritizing design versatility and fabric movement.

Advantages of Using Lock Stitch in Garment Manufacturing

Lock stitch provides superior strength and durability compared to chain stitch, making it ideal for high-stress garment seams. Its interlocking thread pattern minimizes unraveling, ensuring longer-lasting finishes in mass-produced clothing. The consistent stitch tension and neat appearance enhance overall garment quality and customer satisfaction.

Cost Efficiency: Which Stitch Is More Economical?

Chain stitch machines generally have lower initial costs and faster sewing speeds, making them more economical for large-scale production despite higher thread consumption and weaker seam strength. Lock stitch machines, while more expensive upfront and slower, offer stronger, more durable seams that reduce the need for repairs and provide long-term cost savings. For cost efficiency, the choice depends on balancing production volume with the desired durability of the finished product.

Stitch Appearance: Visual Impact in Finished Products

Chain stitch creates a distinctive, textured looped appearance on the fabric's surface, giving a handcrafted and decorative look ideal for embroidery and visible seams. Lock stitch produces a clean, uniform, and flat finish with interlocked threads on both fabric sides, ensuring a professional, polished appearance suitable for seams requiring durability and neatness. The choice between chain stitch and lock stitch greatly influences the visual impact of finished products, with chain stitch offering ornamental appeal and lock stitch providing sleek, minimalistic aesthetics.

Machine Requirements for Chain Stitch and Lock Stitch

Chain stitch machines require fewer components, typically featuring a single thread system with a looper to form interlinked stitches, making them simpler and more cost-effective for lightweight fabrics. Lock stitch machines demand a more complex setup with two threads--needle thread and bobbin thread--necessitating synchronized needle and shuttle mechanisms to produce secure, durable stitches suitable for heavy-duty applications. The mechanical intricacy of lock stitch machines results in higher maintenance but provides superior stitch strength compared to chain stitch machines.

Maintenance and Troubleshooting Tips for Industrial Stitching

Chain stitch machines require regular tension adjustments and frequent oiling to prevent thread breakage and skipped stitches, ensuring smooth operation in industrial settings. Lock stitch machines demand routine needle and bobbin case inspections to avoid thread jams and maintain stitch consistency during high-speed production. Both require cleaning lint buildup from feed dogs and thread paths to enhance performance and reduce machine downtime.

Choosing the Right Stitch for Your Sewing Business

Chain stitch offers flexibility and faster sewing speeds, ideal for decorative work and temporary seams, while lock stitch provides superior strength and durability, making it perfect for garments requiring long-lasting stitches. Selecting the right stitch depends on fabric type, intended garment use, and production scale, with lock stitch machines suitable for high-volume, professional tailoring businesses. Consider stitch tension, thread type, and maintenance requirements to optimize efficiency and product quality in your sewing operations.

Chain stitch vs lock stitch Infographic

bizdif.com

bizdif.com