Overlock stitching creates strong, stretchy seams ideal for sewing pet apparel and accessories that require durability and flexibility. Lockstitch produces neat, secure seams perfect for precise, detailed pet projects where a clean finish is essential. Choosing between overlock and lockstitch depends on the fabric type and the functional demands of the pet item.

Table of Comparison

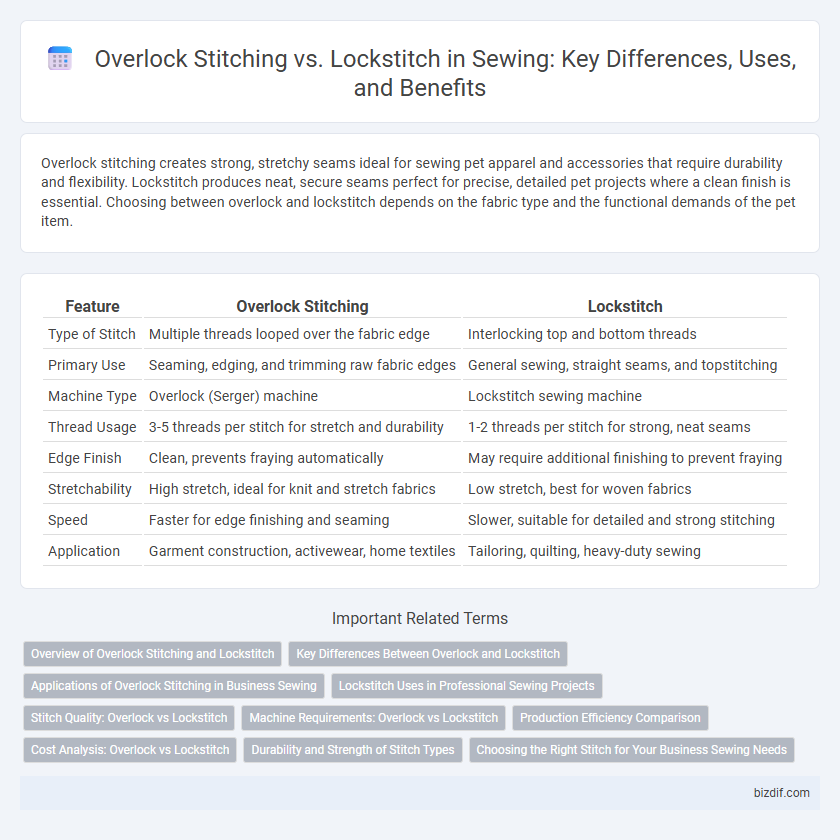

| Feature | Overlock Stitching | Lockstitch |

|---|---|---|

| Type of Stitch | Multiple threads looped over the fabric edge | Interlocking top and bottom threads |

| Primary Use | Seaming, edging, and trimming raw fabric edges | General sewing, straight seams, and topstitching |

| Machine Type | Overlock (Serger) machine | Lockstitch sewing machine |

| Thread Usage | 3-5 threads per stitch for stretch and durability | 1-2 threads per stitch for strong, neat seams |

| Edge Finish | Clean, prevents fraying automatically | May require additional finishing to prevent fraying |

| Stretchability | High stretch, ideal for knit and stretch fabrics | Low stretch, best for woven fabrics |

| Speed | Faster for edge finishing and seaming | Slower, suitable for detailed and strong stitching |

| Application | Garment construction, activewear, home textiles | Tailoring, quilting, heavy-duty sewing |

Overview of Overlock Stitching and Lockstitch

Overlock stitching uses multiple threads to sew over the fabric edge, providing a clean finish and preventing fraying, commonly found in garment construction for stretch fabrics. Lockstitch involves two threads forming a tight, interlocking stitch, known for its strength and durability, often used in seams requiring high tension resistance. Overlock machines typically trim fabric edges while sewing, whereas lockstitch machines focus on precise stitch formation without edge trimming.

Key Differences Between Overlock and Lockstitch

Overlock stitching uses multiple threads to sew over the edge of the fabric, creating a strong seam and preventing fraying, while lockstitch employs two threads interlocked at the fabric's surface for a clean, flat finish. Overlock machines are faster and ideal for finishing seams and hemming stretch fabrics, whereas lockstitch machines provide precise, straight seams suited for detailed sewing tasks. The key difference lies in their construction and application: overlock stitches encase fabric edges, lockstitch forms a single durable seam.

Applications of Overlock Stitching in Business Sewing

Overlock stitching is extensively used in business sewing for finishing garment edges, preventing fraying, and creating strong, flexible seams ideal for knitwear and stretch fabrics. Its efficiency in trimming excess fabric while stitching simultaneously reduces production time, making it invaluable in mass apparel manufacturing and textile production. Overlock stitches also enhance garment durability and comfort, which is critical in activewear, lingerie, and home textiles, boosting overall product quality and customer satisfaction.

Lockstitch Uses in Professional Sewing Projects

Lockstitch is widely used in professional sewing projects for its strong, durable seams ideal for garment construction and upholstery. It creates a neat, balanced stitch on both sides of the fabric, making it suitable for visible seams and high-quality finishes. Lockstitch machines handle a variety of fabrics, from lightweight silks to heavy denim, ensuring versatility in tailoring and industrial sewing applications.

Stitch Quality: Overlock vs Lockstitch

Overlock stitching creates durable, stretchable seams ideal for knit fabrics by interlocking multiple threads around fabric edges, preventing fraying and providing clean finishes. Lockstitch, formed by interlocking top and bottom threads, delivers strong, precise seams suited for woven fabrics but lacks the elasticity found in overlock seams. Stitch quality comparison highlights overlock's superior edge stability and flexibility, while lockstitch offers higher seam strength and neatness for standard garment construction.

Machine Requirements: Overlock vs Lockstitch

Overlock stitching requires a specialized overlock machine equipped with multiple threads and loopers to simultaneously trim fabric edges and sew, making it ideal for finishing seams and preventing fraying. Lockstitch machines, commonly known as standard sewing machines, utilize a needle and bobbin mechanism to create a single line of stitching suitable for most general sewing tasks without fabric trimming capabilities. Overlock machines demand more maintenance and thread management, while lockstitch machines are versatile and widely accessible for basic garment construction.

Production Efficiency Comparison

Overlock stitching significantly enhances production efficiency by simultaneously trimming fabric edges and sewing, reducing the need for separate finishing steps compared to lockstitch, which requires additional seam sealing. Overlock machines operate at higher speeds, often exceeding 1,000 stitches per minute, whereas lockstitch machines typically average 600-900 stitches per minute, leading to faster garment assembly with overlock. The reduced thread breaks and maintenance downtime in overlock stitching further optimize workflow, making it a preferred choice for high-volume apparel manufacturing.

Cost Analysis: Overlock vs Lockstitch

Overlock stitching generally incurs higher equipment costs due to specialized machines and faster thread consumption compared to lockstitch machines, which are more affordable and versatile. Maintenance expenses for overlock machines can also be greater, driven by their intricate loopers and multiple threads, while lockstitch machines require simpler upkeep. When evaluating cost efficiency, overlock stitching reduces fabric waste and sewing time, potentially offsetting initial investments through improved production speed and seam durability.

Durability and Strength of Stitch Types

Overlock stitching creates strong, durable seams by simultaneously trimming and binding fabric edges, preventing fraying and providing elasticity ideal for stretch fabrics. Lockstitch, formed by interlocking two threads in the fabric, offers high stitch strength and durability suitable for non-stretch materials and heavy-duty seams. Both stitch types ensure durability, but overlock excels in edge finishing and flexibility, while lockstitch provides superior tensile strength for reinforced sewing.

Choosing the Right Stitch for Your Business Sewing Needs

Overlock stitching offers superior edge finishing and stretchability, making it ideal for knit fabrics and garments requiring durability in high-stress areas, while lockstitch provides a strong, straight seam suitable for woven fabrics and visible topstitching in professional apparel. Businesses focusing on mass production and versatile fabric compatibility benefit from lockstitch machines due to their precision and ease of maintenance. Selecting the right stitch depends on fabric type, desired seam strength, and aesthetic requirements, ensuring efficient workflow and quality in garment manufacturing.

Overlock stitching vs Lockstitch Infographic

bizdif.com

bizdif.com