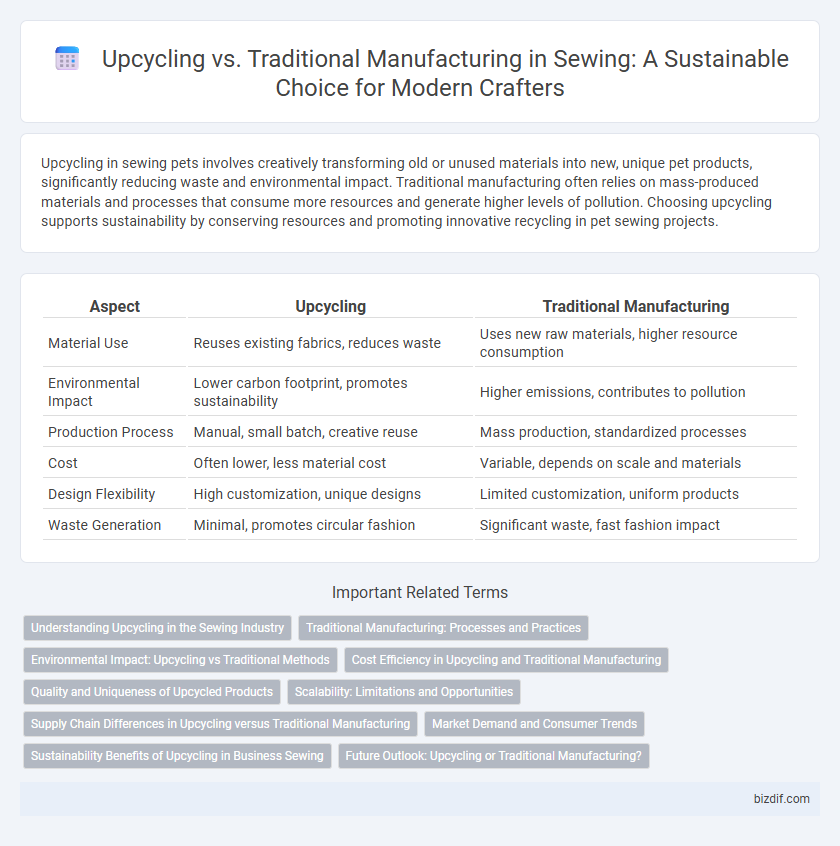

Upcycling in sewing pets involves creatively transforming old or unused materials into new, unique pet products, significantly reducing waste and environmental impact. Traditional manufacturing often relies on mass-produced materials and processes that consume more resources and generate higher levels of pollution. Choosing upcycling supports sustainability by conserving resources and promoting innovative recycling in pet sewing projects.

Table of Comparison

| Aspect | Upcycling | Traditional Manufacturing |

|---|---|---|

| Material Use | Reuses existing fabrics, reduces waste | Uses new raw materials, higher resource consumption |

| Environmental Impact | Lower carbon footprint, promotes sustainability | Higher emissions, contributes to pollution |

| Production Process | Manual, small batch, creative reuse | Mass production, standardized processes |

| Cost | Often lower, less material cost | Variable, depends on scale and materials |

| Design Flexibility | High customization, unique designs | Limited customization, uniform products |

| Waste Generation | Minimal, promotes circular fashion | Significant waste, fast fashion impact |

Understanding Upcycling in the Sewing Industry

Upcycling in the sewing industry transforms discarded fabrics and garments into valuable, unique pieces, reducing waste and conserving resources compared to traditional manufacturing. This sustainable practice minimizes environmental impact by decreasing the need for new raw materials and energy-intensive production processes. Embracing upcycling promotes creativity, supports circular fashion, and aligns with eco-conscious consumer demand for ethical clothing options.

Traditional Manufacturing: Processes and Practices

Traditional manufacturing in sewing involves standardized processes such as pattern making, cutting, stitching, and finishing, utilizing mass production techniques to optimize efficiency and consistency. These practices often rely on industrial machinery, skilled labor, and supply chains to produce large quantities of garments with uniform quality. Emphasis on quality control, material sourcing, and workflow optimization ensures scalability and meets market demand for traditional apparel production.

Environmental Impact: Upcycling vs Traditional Methods

Upcycling in sewing significantly reduces environmental impact by repurposing existing fabrics and materials, minimizing textile waste and lowering carbon emissions compared to traditional manufacturing. Traditional methods often involve resource-intensive processes, including high water usage, chemical treatments, and substantial energy consumption, which contribute to pollution and landfill accumulation. Emphasizing upcycling promotes sustainable fashion practices by extending material life cycles and decreasing the demand for new raw resources.

Cost Efficiency in Upcycling and Traditional Manufacturing

Upcycling clothing reduces material costs by repurposing existing textiles, lowering the need for new fabric purchases and minimizing waste disposal expenses. Traditional manufacturing involves higher costs from raw material procurement, extensive labor, and energy consumption associated with mass production processes. Upcycling's cost efficiency is enhanced by customization and reduced supply chain complexity, making it a sustainable alternative to the traditional garment industry.

Quality and Uniqueness of Upcycled Products

Upcycled sewing projects prioritize quality by transforming pre-existing fabrics into unique, handcrafted garments that showcase distinct patterns and textures impossible to replicate through traditional manufacturing. These products often feature superior durability due to careful material selection and artisanal techniques, contrasting with mass-produced clothing's standardized quality. The inherent singularity of each upcycled piece appeals to consumers seeking personalized fashion with an eco-conscious ethos.

Scalability: Limitations and Opportunities

Upcycling in sewing offers sustainable scalability through repurposing existing fabrics and materials, significantly reducing waste and resource consumption compared to traditional manufacturing. However, upcycling faces limitations in mass production due to variable material supply and inconsistent fabric quality, which can hinder uniformity and efficiency. Traditional manufacturing excels in high-volume scalability with standardized processes and bulk material sourcing, but upcycling presents opportunities for niche markets and customized designs focused on eco-conscious consumers.

Supply Chain Differences in Upcycling versus Traditional Manufacturing

Upcycling in sewing drastically shortens the supply chain by sourcing pre-existing materials, which reduces dependency on raw material extraction and transportation logistics common in traditional manufacturing. Traditional manufacturing involves complex, multi-tiered supply chains including raw fiber production, spinning, dyeing, and fabric creation, leading to higher carbon emissions and waste generation. Upcycling streamlines production processes, lowers environmental impact, and promotes localized, on-demand manufacturing that minimizes storage and shipping requirements.

Market Demand and Consumer Trends

Upcycling in sewing responds to growing market demand for sustainable fashion by transforming existing materials into unique garments, reducing environmental impact compared to traditional manufacturing. Consumer trends increasingly favor custom, eco-friendly products, driving brands to integrate upcycled fabrics and slow fashion practices. Traditional manufacturing still dominates bulk production, but shifting preferences highlight a rise in demand for artisanal, low-waste alternatives that prioritize ethical sourcing and resource conservation.

Sustainability Benefits of Upcycling in Business Sewing

Upcycling in business sewing significantly reduces textile waste by repurposing discarded fabrics, minimizing the demand for new raw materials and lowering overall carbon footprints. This sustainable practice conserves water and energy typically consumed in traditional manufacturing processes, promoting eco-friendly production cycles. Embracing upcycling also fosters a circular economy, enhancing brand reputation while meeting growing consumer demand for environmentally responsible fashion.

Future Outlook: Upcycling or Traditional Manufacturing?

Upcycling in sewing offers sustainable solutions by transforming old fabrics into unique garments, reducing textile waste and environmental impact compared to traditional manufacturing methods that rely heavily on resource-intensive processes. The future outlook favors upcycling as consumer demand grows for eco-friendly fashion and circular economy models gain traction in the apparel industry. Integrating innovative technologies with upcycling practices will likely redefine production standards, making it a crucial component of sustainable fashion's evolution.

Upcycling vs Traditional Manufacturing Infographic

bizdif.com

bizdif.com