Quality control in sewing pets involves inspecting finished products to identify defects and ensure they meet specific standards, while quality assurance encompasses the entire production process to prevent errors and maintain consistent quality. Quality assurance implements systematic procedures and training to minimize variability, whereas quality control is a reactive approach that detects issues after production. Together, these strategies optimize the durability, safety, and appearance of sewn pet items.

Table of Comparison

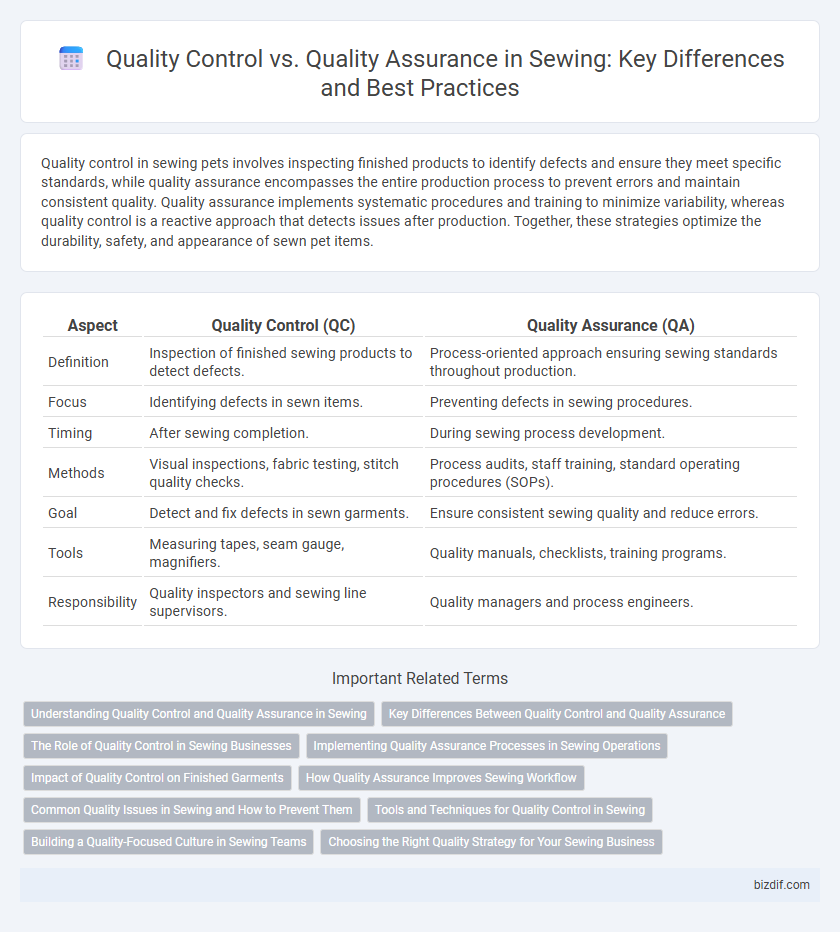

| Aspect | Quality Control (QC) | Quality Assurance (QA) |

|---|---|---|

| Definition | Inspection of finished sewing products to detect defects. | Process-oriented approach ensuring sewing standards throughout production. |

| Focus | Identifying defects in sewn items. | Preventing defects in sewing procedures. |

| Timing | After sewing completion. | During sewing process development. |

| Methods | Visual inspections, fabric testing, stitch quality checks. | Process audits, staff training, standard operating procedures (SOPs). |

| Goal | Detect and fix defects in sewn garments. | Ensure consistent sewing quality and reduce errors. |

| Tools | Measuring tapes, seam gauge, magnifiers. | Quality manuals, checklists, training programs. |

| Responsibility | Quality inspectors and sewing line supervisors. | Quality managers and process engineers. |

Understanding Quality Control and Quality Assurance in Sewing

Quality control in sewing involves inspecting and testing finished garments to ensure they meet specific standards for stitching, fabric integrity, and overall craftsmanship. Quality assurance focuses on implementing systematic processes throughout the sewing production line to prevent defects and maintain consistent product quality. Understanding these concepts helps manufacturers reduce errors, improve efficiency, and deliver sewing products that satisfy customer expectations.

Key Differences Between Quality Control and Quality Assurance

Quality control in sewing involves the inspection and identification of defects in finished garments, ensuring adherence to predefined standards through testing and measurement. Quality assurance focuses on the entire production process, implementing systematic procedures and standards to prevent defects and maintain consistent product quality. Key differences include quality control being product-oriented and reactive, while quality assurance is process-oriented and proactive, emphasizing prevention over correction.

The Role of Quality Control in Sewing Businesses

Quality control in sewing businesses involves systematic inspection and testing of garments to ensure they meet specified standards for stitch strength, fabric integrity, and overall workmanship. It plays a crucial role in identifying defects such as loose threads, misaligned patterns, or inconsistent seam allowances before products reach customers. By maintaining rigorous quality control protocols, sewing manufacturers reduce returns, enhance brand reputation, and improve customer satisfaction.

Implementing Quality Assurance Processes in Sewing Operations

Implementing quality assurance processes in sewing operations involves systematic monitoring of production techniques and fabric handling to prevent defects and ensure consistent garment standards. Incorporating standardized inspection checkpoints and employee training enhances the reliability of stitching and seam integrity across batches. Emphasizing quality assurance over quality control shifts the focus from detecting errors to embedding quality in every step of the sewing workflow.

Impact of Quality Control on Finished Garments

Quality control in sewing ensures finished garments meet specific standards by inspecting for defects such as loose threads, uneven stitching, and fabric flaws, which directly affects product reliability and customer satisfaction. Implementing rigorous quality control processes reduces returns and enhances brand reputation by delivering consistent garment quality. These inspections during production stages prevent costly rework and waste, ultimately improving overall manufacturing efficiency.

How Quality Assurance Improves Sewing Workflow

Quality assurance in sewing enhances workflow by implementing standardized processes that reduce errors and ensure consistent fabric handling and stitching quality. Continuous monitoring and feedback loops help identify defects early, preventing costly rework and material waste. This proactive approach leads to increased productivity, better product durability, and higher customer satisfaction in garment manufacturing.

Common Quality Issues in Sewing and How to Prevent Them

Common quality issues in sewing include thread breakage, uneven stitching, fabric puckering, and misaligned seams, which can compromise garment durability and appearance. Implementing stringent quality control measures such as regular machine maintenance, operator training, and real-time inspection helps detect defects early in the production process. Quality assurance emphasizes standardized sewing procedures, proper fabric handling, and consistent use of high-quality threads and needles to prevent defects and ensure overall garment integrity.

Tools and Techniques for Quality Control in Sewing

Quality control in sewing employs tools like fabric inspection machines, seam gauges, and thread tension meters to identify defects and ensure stitching precision. Techniques such as visual inspections, stitch length measurement, and defect mapping help maintain consistent garment quality. These methods enable early detection of errors, minimizing rework and enhancing overall production efficiency.

Building a Quality-Focused Culture in Sewing Teams

Quality control in sewing involves inspecting finished garments to identify defects, while quality assurance focuses on implementing processes that prevent errors throughout production. Building a quality-focused culture within sewing teams requires ongoing training, standardized procedures, and employee accountability to ensure consistency and craftsmanship. Emphasizing collaboration and continuous improvement drives higher product durability and customer satisfaction.

Choosing the Right Quality Strategy for Your Sewing Business

Quality control in sewing involves inspecting finished garments to identify defects and ensure adherence to specified standards, while quality assurance focuses on implementing systematic processes throughout production to prevent errors. Choosing the right quality strategy for your sewing business requires balancing both approaches to enhance product reliability, minimize waste, and maintain customer satisfaction. Integrating quality assurance protocols with rigorous quality control checks optimizes operational efficiency and strengthens brand reputation in the competitive apparel industry.

Quality control vs Quality assurance Infographic

bizdif.com

bizdif.com