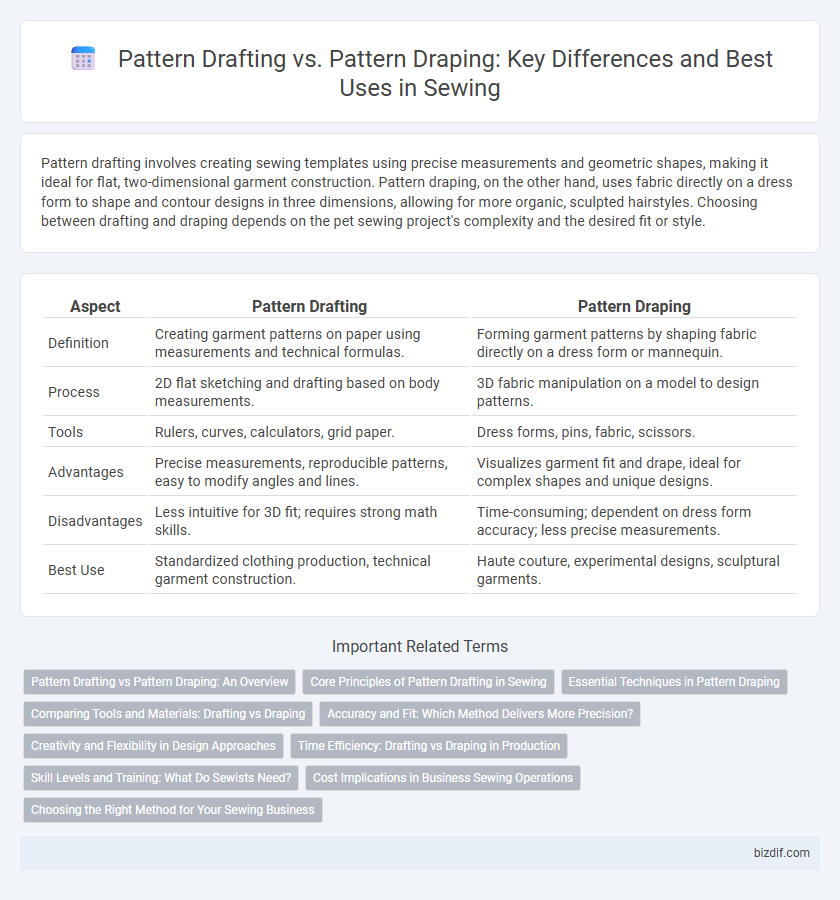

Pattern drafting involves creating sewing templates using precise measurements and geometric shapes, making it ideal for flat, two-dimensional garment construction. Pattern draping, on the other hand, uses fabric directly on a dress form to shape and contour designs in three dimensions, allowing for more organic, sculpted hairstyles. Choosing between drafting and draping depends on the pet sewing project's complexity and the desired fit or style.

Table of Comparison

| Aspect | Pattern Drafting | Pattern Draping |

|---|---|---|

| Definition | Creating garment patterns on paper using measurements and technical formulas. | Forming garment patterns by shaping fabric directly on a dress form or mannequin. |

| Process | 2D flat sketching and drafting based on body measurements. | 3D fabric manipulation on a model to design patterns. |

| Tools | Rulers, curves, calculators, grid paper. | Dress forms, pins, fabric, scissors. |

| Advantages | Precise measurements, reproducible patterns, easy to modify angles and lines. | Visualizes garment fit and drape, ideal for complex shapes and unique designs. |

| Disadvantages | Less intuitive for 3D fit; requires strong math skills. | Time-consuming; dependent on dress form accuracy; less precise measurements. |

| Best Use | Standardized clothing production, technical garment construction. | Haute couture, experimental designs, sculptural garments. |

Pattern Drafting vs Pattern Draping: An Overview

Pattern drafting involves creating flat, two-dimensional templates using precise measurements and technical drawings, ensuring accuracy and repeatability in garment construction. Pattern draping, on the other hand, is a sculptural technique where fabric is pinned and shaped directly on a dress form to develop three-dimensional garment shapes and design details. Both methods are essential in fashion design, with drafting offering precision for mass production and draping providing creative flexibility for custom fits.

Core Principles of Pattern Drafting in Sewing

Pattern drafting in sewing relies on precise measurements and mathematical calculations to create templates based on body dimensions, ensuring accuracy and fit. Emphasizing geometric shapes and flat pattern manipulation, it allows for reproducible and scalable garment designs. Core principles include balance, proportion, and ease, which collectively contribute to the structural foundation of garment construction.

Essential Techniques in Pattern Draping

Pattern draping involves manipulating fabric directly on a dress form to create three-dimensional designs, which enhances precision in fitting complex curves and contours. Essential techniques in pattern draping include fabric pinning, clipping, and marking to shape the fabric accurately, as well as utilizing muslin cloth for initial mock-ups to perfect the fit. This hands-on approach allows designers to visualize and adjust garment structure dynamically, ensuring a tailored fit that flat pattern drafting may not achieve.

Comparing Tools and Materials: Drafting vs Draping

Pattern drafting relies on flat tools such as rulers, french curves, and drafting paper to create precise, measured garment templates based on body dimensions and design specifications. Draping utilizes three-dimensional materials like muslin fabric, dress forms, pins, and marking tools to mold fabric directly on a mannequin, allowing designers to visualize fit and volume in real time. Drafting emphasizes accuracy through mathematical calculations and flat geometry, whereas draping prioritizes tactile manipulation and spatial creativity.

Accuracy and Fit: Which Method Delivers More Precision?

Pattern drafting utilizes exact measurements and mathematical calculations to create precise garment templates, ensuring consistent accuracy and fit across multiple sizes. Pattern draping involves manipulating fabric directly on a dress form, allowing a more intuitive and customized fit that adapts to three-dimensional body contours. While drafting excels in reproducibility and standardized sizing, draping offers superior precision for unique, complex designs requiring exact body conformity.

Creativity and Flexibility in Design Approaches

Pattern drafting involves creating flat, precise templates based on measurements and technical specifications, offering high accuracy and consistency in garment construction. Pattern draping allows designers to shape fabric directly on a dress form, fostering creativity and real-time adjustments for organic, three-dimensional designs. Combining both methods enhances flexibility, enabling innovative and tailored fashion designs that balance structure with artistic expression.

Time Efficiency: Drafting vs Draping in Production

Pattern drafting significantly reduces production time by using precise measurements and digital tools to create flat templates, enabling faster replication and adjustments. Pattern draping, while offering detailed three-dimensional garment fitting, demands more time due to fabric manipulation on dress forms and iterative refining. In mass production, drafting enhances efficiency, whereas draping suits bespoke or complex designs where fit customization justifies the additional time investment.

Skill Levels and Training: What Do Sewists Need?

Pattern drafting requires strong technical skills in measurements, geometry, and precision, making it ideal for sewists comfortable with mathematical concepts and detailed planning. Pattern draping involves manipulating fabric directly on a dress form, demanding a more intuitive understanding of fabric behavior and design aesthetics, suitable for those with hands-on experience and creative flair. Sewists aiming to master either method benefit from targeted training: drafting courses emphasize accuracy and technical knowledge, while draping workshops enhance spatial awareness and fabric manipulation techniques.

Cost Implications in Business Sewing Operations

Pattern drafting involves creating precise, scalable templates on paper or digitally, which reduces material waste and supports efficient mass production, lowering overall costs in sewing operations. Pattern draping requires fabric manipulation on a dress form, often consuming more material and labor time, leading to higher expenses in prototype development and custom garment manufacturing. Businesses must weigh initial drafting setup costs against the flexible yet costlier draping process for optimized budgeting and resource allocation.

Choosing the Right Method for Your Sewing Business

Pattern drafting relies on precise measurements and mathematical calculations to create flat patterns, making it ideal for mass production and standard sizing in a sewing business. Pattern draping involves manipulating fabric on a dress form to develop three-dimensional designs, offering greater creativity and customization for bespoke garments. Selecting the right method depends on your business goals, whether prioritizing efficiency and scalability with drafting or unique, tailored designs with draping.

Pattern drafting vs pattern draping Infographic

bizdif.com

bizdif.com