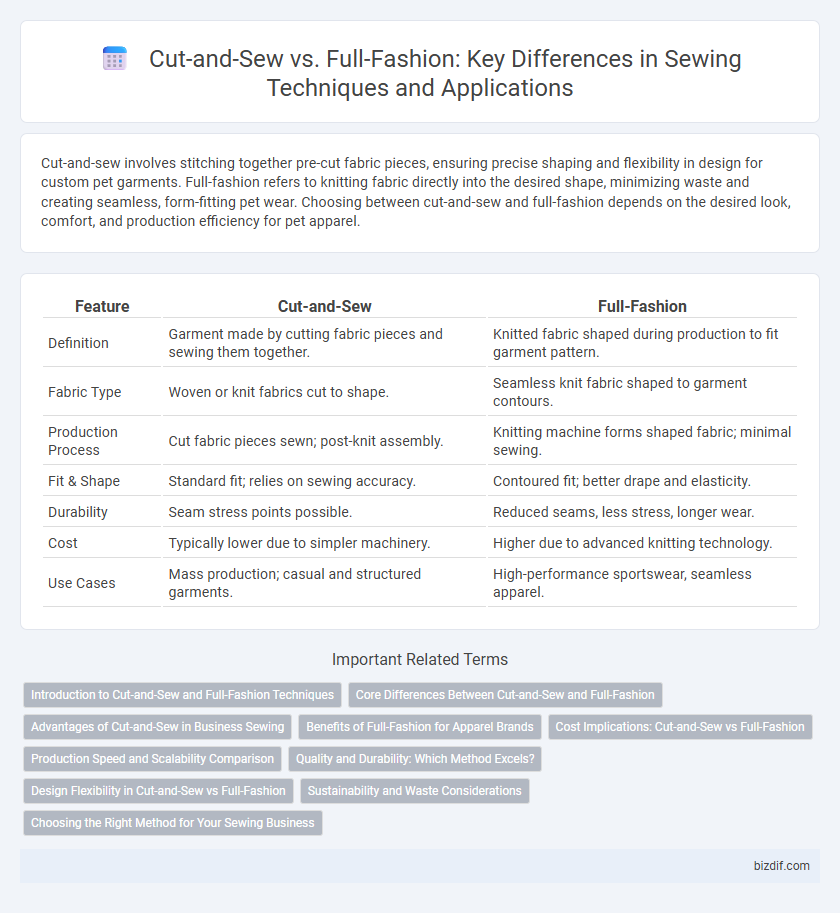

Cut-and-sew involves stitching together pre-cut fabric pieces, ensuring precise shaping and flexibility in design for custom pet garments. Full-fashion refers to knitting fabric directly into the desired shape, minimizing waste and creating seamless, form-fitting pet wear. Choosing between cut-and-sew and full-fashion depends on the desired look, comfort, and production efficiency for pet apparel.

Table of Comparison

| Feature | Cut-and-Sew | Full-Fashion |

|---|---|---|

| Definition | Garment made by cutting fabric pieces and sewing them together. | Knitted fabric shaped during production to fit garment pattern. |

| Fabric Type | Woven or knit fabrics cut to shape. | Seamless knit fabric shaped to garment contours. |

| Production Process | Cut fabric pieces sewn; post-knit assembly. | Knitting machine forms shaped fabric; minimal sewing. |

| Fit & Shape | Standard fit; relies on sewing accuracy. | Contoured fit; better drape and elasticity. |

| Durability | Seam stress points possible. | Reduced seams, less stress, longer wear. |

| Cost | Typically lower due to simpler machinery. | Higher due to advanced knitting technology. |

| Use Cases | Mass production; casual and structured garments. | High-performance sportswear, seamless apparel. |

Introduction to Cut-and-Sew and Full-Fashion Techniques

Cut-and-sew techniques involve cutting fabric pieces before assembling them into garments, allowing for precise pattern placement and customization. Full-fashion techniques knit the garment to shape, minimizing fabric waste and enhancing fit by shaping the fabric during production. Understanding these methods is essential for choosing the right approach in apparel manufacturing based on design complexity and production efficiency.

Core Differences Between Cut-and-Sew and Full-Fashion

Cut-and-sew garments are created by stitching together pre-cut fabric pieces, allowing for greater design flexibility and a wider range of fabric choices. Full-fashion knitting produces shaped garments directly on the knitting machine, minimizing fabric waste and enhancing fit through precise shaping techniques. Core differences include production methods, fabric utilization, and garment fit customization.

Advantages of Cut-and-Sew in Business Sewing

Cut-and-Sew offers significant advantages in business sewing due to its versatility and cost-effectiveness, allowing for greater customization with various fabrics and complex designs. This method supports rapid prototyping and small batch production, accelerating time-to-market while minimizing inventory risks. Higher scalability and easier quality control also contribute to improved operational efficiency and customer satisfaction in apparel manufacturing.

Benefits of Full-Fashion for Apparel Brands

Full-Fashion knitting offers apparel brands precise control over garment shape and fit by knitting pieces to exact measurements, minimizing fabric waste and reducing post-production labor costs. This method enhances product quality and consistency, leading to improved customer satisfaction and brand reputation. Additionally, Full-Fashion allows for complex design details and seamless integration of patterns, elevating the aesthetic appeal and marketability of the clothing line.

Cost Implications: Cut-and-Sew vs Full-Fashion

Cut-and-sew manufacturing typically incurs higher costs due to the complex process of cutting individual fabric pieces and assembling them, often resulting in greater labor and material waste. Full-fashion knitting reduces expenses by shaping garments directly on the knitting machine, minimizing material waste and streamlining production. Brands balancing quality and budget often choose full-fashion techniques for efficient, cost-effective apparel manufacturing.

Production Speed and Scalability Comparison

Cut-and-sew production offers faster turnaround times due to its streamlined process of assembling pre-cut fabric pieces, making it ideal for large-scale manufacturing with consistent quality. Full-fashion knitting, while providing intricate shaping and minimal material waste, typically requires longer production cycles and specialized machinery, limiting scalability. Consequently, cut-and-sew methods are preferred for rapid, high-volume garment production, whereas full-fashion is better suited for smaller, customized runs with complex designs.

Quality and Durability: Which Method Excels?

Cut-and-sew techniques allow precise pattern matching and custom fabric choices, enhancing garment quality with tailored durability. Full-fashion knitting integrates shaping during production, reducing seams and fabric waste while maintaining elasticity and fit for long-lasting wear. Both methods offer high-quality results, but cut-and-sew garments often excel in structural strength, while full-fashion pieces provide superior stretch and comfort.

Design Flexibility in Cut-and-Sew vs Full-Fashion

Cut-and-sew techniques offer greater design flexibility by allowing individual fabric pieces to be shaped and assembled, enabling customized patterns and complex garment silhouettes. Full-fashion knitting shapes the fabric during the knitting process, limiting adjustments and design modifications post-production. This makes cut-and-sew ideal for intricate designs requiring precise control over fabric placement and fit.

Sustainability and Waste Considerations

Cut-and-sew production typically generates more fabric waste due to the pattern-cutting process, whereas full-fashion knitting shapes garments during knitting, minimizing offcuts and enhancing sustainability. Full-fashion techniques reduce waste by creating pieces that fit the design specifications without excess fabric trimming, leading to more efficient material use. Brands prioritizing eco-friendly practices often prefer full-fashion methods to lower environmental impact through waste reduction and resource optimization.

Choosing the Right Method for Your Sewing Business

Cut-and-Sew involves assembling pre-cut fabric pieces, ideal for businesses aiming for quick production and diverse design options. Full-Fashion requires knitting garments to exact shapes, offering superior fit and durability suited for premium, high-quality products. Selecting the right method depends on factors like production volume, fabric type, design complexity, and target market demands.

Cut-and-Sew vs Full-Fashion Infographic

bizdif.com

bizdif.com