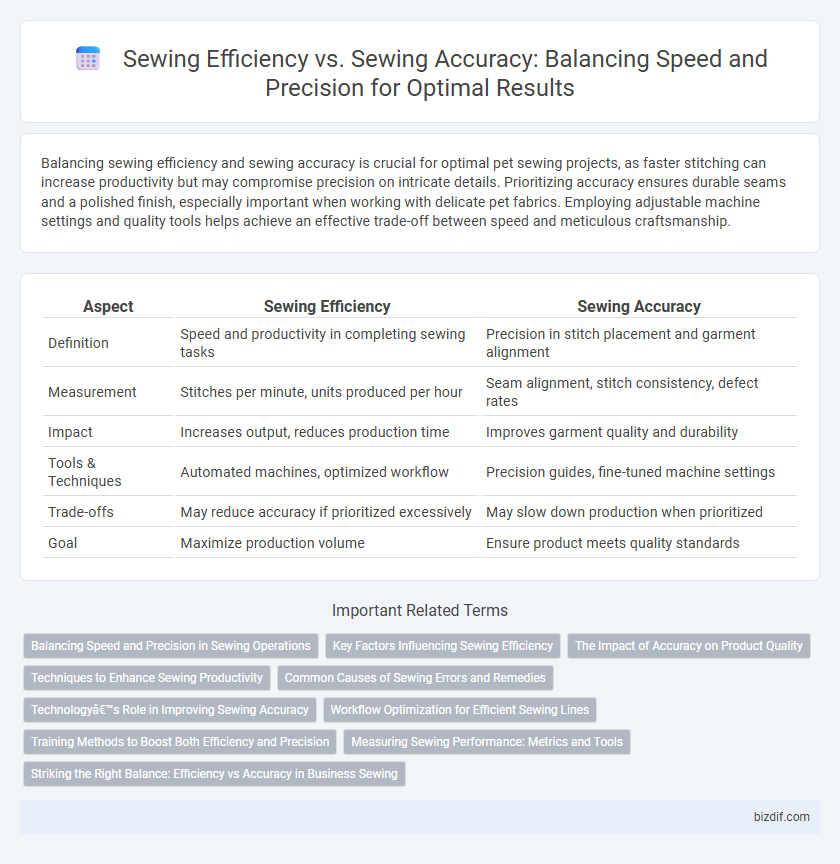

Balancing sewing efficiency and sewing accuracy is crucial for optimal pet sewing projects, as faster stitching can increase productivity but may compromise precision on intricate details. Prioritizing accuracy ensures durable seams and a polished finish, especially important when working with delicate pet fabrics. Employing adjustable machine settings and quality tools helps achieve an effective trade-off between speed and meticulous craftsmanship.

Table of Comparison

| Aspect | Sewing Efficiency | Sewing Accuracy |

|---|---|---|

| Definition | Speed and productivity in completing sewing tasks | Precision in stitch placement and garment alignment |

| Measurement | Stitches per minute, units produced per hour | Seam alignment, stitch consistency, defect rates |

| Impact | Increases output, reduces production time | Improves garment quality and durability |

| Tools & Techniques | Automated machines, optimized workflow | Precision guides, fine-tuned machine settings |

| Trade-offs | May reduce accuracy if prioritized excessively | May slow down production when prioritized |

| Goal | Maximize production volume | Ensure product meets quality standards |

Balancing Speed and Precision in Sewing Operations

Maximizing sewing efficiency requires a strategic balance between speed and precision to ensure high-quality results without compromising productivity. Implementing optimized stitch patterns, using advanced sewing machines with adjustable speed controls, and maintaining consistent fabric handling techniques enhance both sewing accuracy and operational speed. Prioritizing this balance minimizes errors and material waste, ultimately improving overall workflow in garment production.

Key Factors Influencing Sewing Efficiency

Key factors influencing sewing efficiency include stitch speed, machine maintenance, and operator skill level, which directly impact production output and quality consistency. Fabric type and complexity of the sewing pattern also play a crucial role in determining how quickly and accurately sewing tasks can be completed. Optimizing thread tension and needle type further enhances sewing efficiency by reducing material waste and minimizing rework.

The Impact of Accuracy on Product Quality

Sewing accuracy directly influences product quality by ensuring consistent stitch length, precise seam alignment, and uniform tension, which prevents defects such as puckering or seam slippage. Precise stitching enhances the garment's durability, appearance, and fit, reducing the need for costly rework or returns. Maintaining high sewing accuracy is critical for meeting industry standards and customer satisfaction in textile manufacturing.

Techniques to Enhance Sewing Productivity

Optimizing sewing efficiency relies heavily on mastering techniques such as precise fabric cutting, consistent stitch length, and proper machine maintenance, which minimize machine downtime and material waste. Employing automated tools like pattern-making software and programmable sewing machines enhances sewing accuracy, ensuring consistent seam quality and reducing error rates. Balancing speed with precision through advanced techniques like needle threading aids and tension adjustments significantly boosts overall sewing productivity.

Common Causes of Sewing Errors and Remedies

Common causes of sewing errors include improper machine calibration, incorrect thread tension, and using the wrong needle type for fabric. Remedies focus on regular machine maintenance, precise adjustment of tension settings, and selecting needles compatible with the fabric's weight and texture. Addressing these factors enhances both sewing efficiency and accuracy, reducing fabric waste and improving garment quality.

Technology’s Role in Improving Sewing Accuracy

Advanced sewing technologies like computerized sewing machines and automated embroidery systems significantly enhance sewing accuracy by enabling precise stitch placement and consistent thread tension. Integration of digital pattern recognition and real-time error detection software reduces human error and material waste, improving overall efficiency without compromising quality. These innovations streamline the sewing process and elevate production standards in textile manufacturing.

Workflow Optimization for Efficient Sewing Lines

Optimizing workflow in sewing lines enhances efficiency by minimizing machine idle time and streamlining material handling while maintaining high sewing accuracy through precise stitching techniques and consistent quality control measures. Implementing automated fabric feeders and real-time monitoring systems reduces defects and rework, directly impacting production speed and product reliability. Balancing sewing efficiency and accuracy ensures maximum output with minimal waste, driving cost-effective manufacturing in garment production.

Training Methods to Boost Both Efficiency and Precision

Implementing targeted training methods such as hands-on workshops and simulation-based practice significantly enhances sewing efficiency by reducing stitch errors and cycle time. Emphasizing muscle memory development alongside precision techniques ensures consistent stitch accuracy without compromising speed. Utilizing real-time feedback tools and performance analytics fosters continuous improvement in both sewing speed and quality.

Measuring Sewing Performance: Metrics and Tools

Measuring sewing performance requires balancing sewing efficiency and sewing accuracy through precise metrics such as stitch quality, machine speed, and defect rate. Tools like computerized sewing monitors and vision inspection systems provide real-time data on seam consistency, thread tension, and error detection. Optimizing these metrics enhances overall production quality while minimizing material waste and rework time.

Striking the Right Balance: Efficiency vs Accuracy in Business Sewing

Achieving the right balance between sewing efficiency and sewing accuracy is crucial for optimizing business productivity and product quality. Prioritizing efficiency can boost output and reduce costs, but excessive speed may compromise stitch precision, leading to defective garments and increased rework. Implementing advanced sewing machines with automated tension control and investing in skilled operators ensures high accuracy without sacrificing throughput in commercial sewing operations.

Sewing Efficiency vs Sewing Accuracy Infographic

bizdif.com

bizdif.com