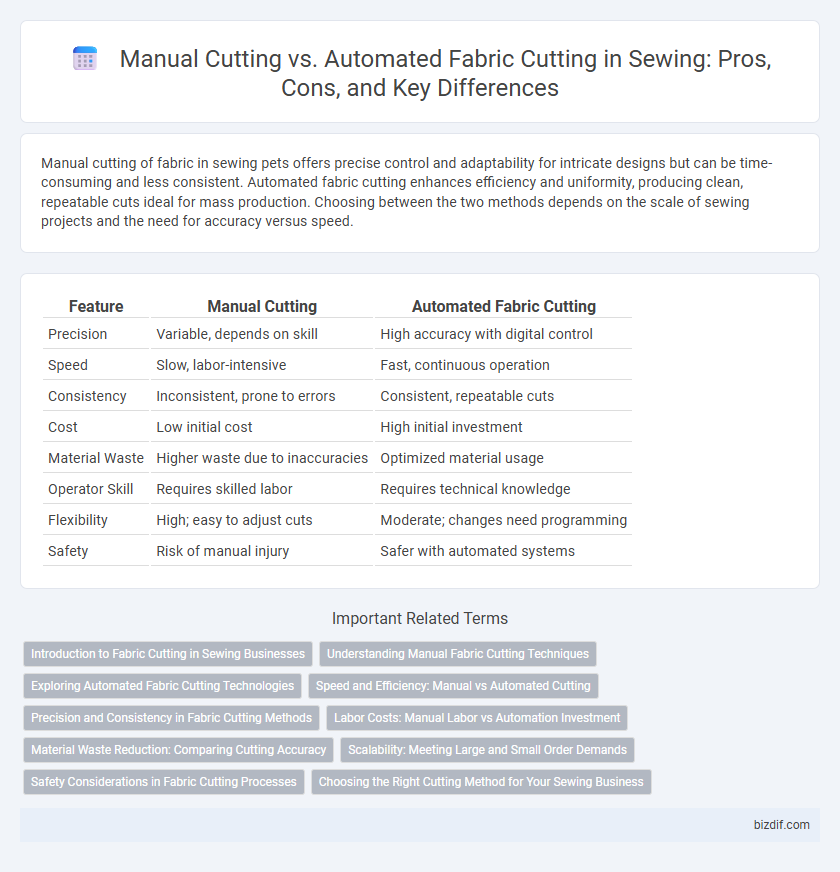

Manual cutting of fabric in sewing pets offers precise control and adaptability for intricate designs but can be time-consuming and less consistent. Automated fabric cutting enhances efficiency and uniformity, producing clean, repeatable cuts ideal for mass production. Choosing between the two methods depends on the scale of sewing projects and the need for accuracy versus speed.

Table of Comparison

| Feature | Manual Cutting | Automated Fabric Cutting |

|---|---|---|

| Precision | Variable, depends on skill | High accuracy with digital control |

| Speed | Slow, labor-intensive | Fast, continuous operation |

| Consistency | Inconsistent, prone to errors | Consistent, repeatable cuts |

| Cost | Low initial cost | High initial investment |

| Material Waste | Higher waste due to inaccuracies | Optimized material usage |

| Operator Skill | Requires skilled labor | Requires technical knowledge |

| Flexibility | High; easy to adjust cuts | Moderate; changes need programming |

| Safety | Risk of manual injury | Safer with automated systems |

Introduction to Fabric Cutting in Sewing Businesses

Manual cutting involves skilled professionals using scissors or rotary cutters to precisely cut fabric, offering flexibility for small-scale or customized sewing businesses. Automated fabric cutting utilizes computer-controlled machines like CNC cutters or laser cutters, enhancing accuracy, speed, and consistency for large-scale production. Choosing between manual and automated methods depends on factors such as production volume, fabric type, and budget constraints in sewing enterprises.

Understanding Manual Fabric Cutting Techniques

Manual fabric cutting techniques require skilled hand precision to follow patterns accurately, ensuring minimal fabric waste and maintaining fabric grain integrity. Techniques such as using sharp shears, rotary cutters, and careful marking are essential for controlling cuts in complex or delicate materials. Mastery of manual cutting enhances customization and flexibility, particularly in small-scale or bespoke garment production where automation may lack sensitivity.

Exploring Automated Fabric Cutting Technologies

Automated fabric cutting technologies utilize advanced computer-aided design (CAD) software and precision cutting machines such as laser cutters, rotary blades, and water jets to enhance accuracy and reduce fabric waste compared to manual cutting. These technologies increase production speed, maintain consistent quality across textile batches, and integrate seamlessly with modern apparel manufacturing workflows. Adoption of automated cutting systems results in significant cost savings, higher throughput, and improved scalability for fashion and upholstery industries.

Speed and Efficiency: Manual vs Automated Cutting

Automated fabric cutting significantly outperforms manual cutting in speed, processing hundreds of layers and intricate patterns within minutes compared to the slower, labor-intensive manual methods. Efficiency gains stem from precise, computer-controlled movements that minimize fabric waste and reduce human error. This acceleration in production timelines enhances overall manufacturing productivity and cost-effectiveness in the sewing industry.

Precision and Consistency in Fabric Cutting Methods

Automated fabric cutting ensures superior precision and consistency compared to manual cutting by utilizing computer-controlled blades or lasers that follow exact digital patterns, reducing human error significantly. Manual cutting, while flexible for small batches and intricate designs, often results in variable seam allowances and material wastage due to inconsistent hand movements. High-precision automated cutters increase efficiency in mass production environments, optimizing fabric utilization and maintaining uniformity across thousands of garments.

Labor Costs: Manual Labor vs Automation Investment

Manual fabric cutting requires intensive labor hours and skill, leading to higher ongoing labor costs and potential inconsistencies in production quality. Automated fabric cutting systems demand substantial initial investment in machinery and technology but significantly reduce labor expenses over time by increasing precision and throughput. Businesses must weigh the upfront automation costs against long-term savings in labor to optimize production efficiency and cost-effectiveness.

Material Waste Reduction: Comparing Cutting Accuracy

Manual cutting in sewing often leads to increased material waste due to variability in human precision, whereas automated fabric cutting machines utilize advanced algorithms and precise blade control to minimize cutting errors. Automated cutting systems reduce fabric offcuts by optimizing marker placement and ensuring consistent cuts, which enhances fabric utilization and lowers production costs. Improved accuracy in automated cutting directly contributes to sustainable practices by significantly decreasing material waste compared to traditional manual methods.

Scalability: Meeting Large and Small Order Demands

Manual cutting offers flexibility and precision for small order demands, making it ideal for custom or intricate fabric designs. Automated fabric cutting systems excel in scalability by rapidly processing large volumes with consistent accuracy, reducing production time and labor costs. Integrating automated cutting technology enables manufacturers to efficiently meet both large-scale production needs and smaller, customized orders without compromising quality.

Safety Considerations in Fabric Cutting Processes

Manual cutting in fabric processes requires strict adherence to safety protocols to prevent injuries from sharp tools and repetitive strain. Automated fabric cutting systems enhance safety by reducing direct human contact with blades, incorporating protective guards, and utilizing sensors to stop machines if abnormalities occur. Choosing automated cutting technology significantly minimizes workplace accidents and improves overall operational safety in textile manufacturing.

Choosing the Right Cutting Method for Your Sewing Business

Selecting the appropriate cutting method depends on factors such as fabric volume, precision requirements, and budget constraints. Manual cutting offers flexibility and lower initial costs, making it ideal for small-scale or custom sewing projects, while automated fabric cutting ensures speed, accuracy, and consistency suitable for large-scale production. Balancing efficiency with quality control is essential to optimize workflow and reduce material waste in any sewing business.

Manual cutting vs Automated fabric cutting Infographic

bizdif.com

bizdif.com