Single-needle sewing offers precision and control, ideal for detailed stitching and delicate fabrics in sewing pet accessories. Double-needle sewing provides stronger, more durable seams, perfect for heavy-duty items like pet harnesses and reinforced collars. Choosing between single-needle and double-needle sewing depends on the specific strength and aesthetic requirements of the pet product.

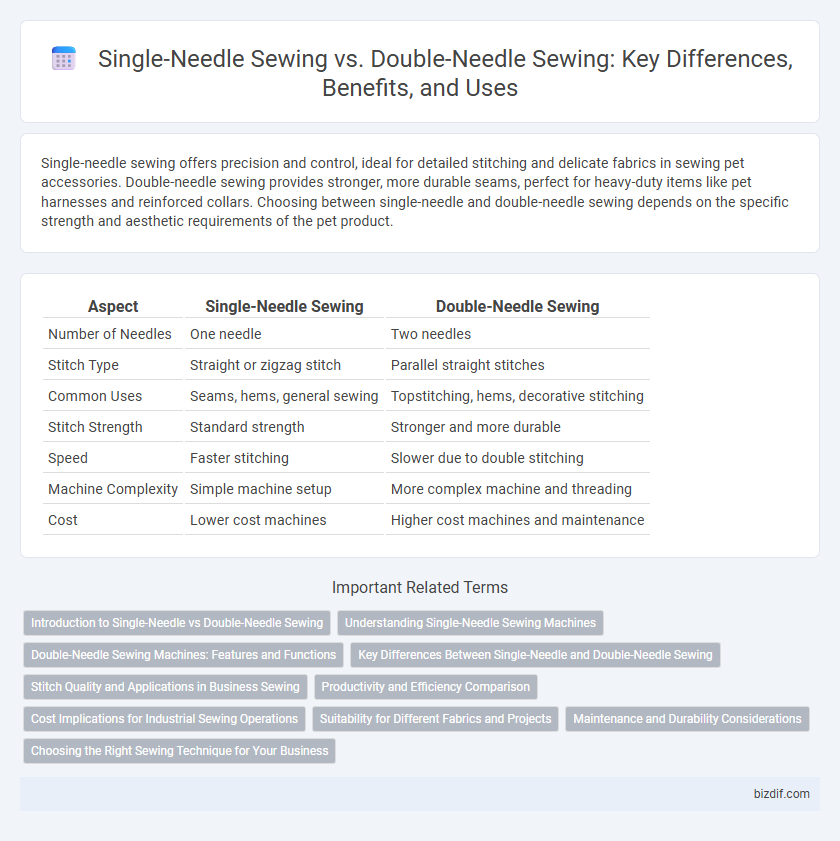

Table of Comparison

| Aspect | Single-Needle Sewing | Double-Needle Sewing |

|---|---|---|

| Number of Needles | One needle | Two needles |

| Stitch Type | Straight or zigzag stitch | Parallel straight stitches |

| Common Uses | Seams, hems, general sewing | Topstitching, hems, decorative stitching |

| Stitch Strength | Standard strength | Stronger and more durable |

| Speed | Faster stitching | Slower due to double stitching |

| Machine Complexity | Simple machine setup | More complex machine and threading |

| Cost | Lower cost machines | Higher cost machines and maintenance |

Introduction to Single-Needle vs Double-Needle Sewing

Single-needle sewing uses one needle to create straight, precise stitches ideal for detailed garment construction and fine fabrics, ensuring strong seams with minimal bulk. Double-needle sewing employs two parallel needles to simultaneously form two rows of stitching, providing enhanced durability and decorative topstitching, commonly used in denim and knitwear. Choosing between single-needle and double-needle sewing depends on fabric type, desired seam strength, and aesthetic requirements in garment manufacturing.

Understanding Single-Needle Sewing Machines

Single-needle sewing machines are essential for precise stitching and detailed garment construction, offering superior control and versatility for various fabrics. These machines operate with one needle and one thread, making them ideal for straight stitching, topstitching, and basic seam work in apparel manufacturing. Understanding single-needle sewing is crucial for tailoring, alterations, and professional-quality textile production due to its accuracy and ease of use.

Double-Needle Sewing Machines: Features and Functions

Double-needle sewing machines feature two needles working simultaneously to create parallel stitches, ideal for hemming and decorative topstitching on garments and home textiles. These machines often include adjustable needle spacing, allowing customization for various stitch widths and fabric types, enhancing both functionality and versatility. With synchronized needle movement and dual bobbins, they ensure strong, durable seams suitable for heavy fabrics like denim and upholstery.

Key Differences Between Single-Needle and Double-Needle Sewing

Single-needle sewing uses one needle to create a single line of stitching, providing precision and detailed work ideal for garment construction and repairs. Double-needle sewing employs two needles simultaneously, producing parallel rows of stitches that enhance fabric durability and decorative finishes. Key differences include stitch strength, sewing speed, and the type of stitch pattern achievable, with single-needle offering versatility while double-needle excels in reinforcement and aesthetic appeal.

Stitch Quality and Applications in Business Sewing

Single-needle sewing produces precise, clean stitches ideal for detailed garment construction and high-quality finishes, making it preferred in tailored clothing and luxury apparel businesses. Double-needle sewing creates parallel rows of stitches, enhancing seam strength and durability, which suits heavy-duty fabrics and mass production in workwear and upholstery industries. Businesses choose single-needle for fine stitching accuracy and double-needle for efficiency and robust seam performance in high-volume production.

Productivity and Efficiency Comparison

Single-needle sewing offers precise stitch control and is ideal for detailed or intricate work, resulting in slower production rates compared to double-needle sewing. Double-needle sewing significantly enhances productivity by stitching two parallel lines simultaneously, doubling output and improving seam strength for mass production. Efficiency in garment manufacturing often favors double-needle machines due to reduced sewing time and consistent stitch quality, making them preferable for large-scale operations.

Cost Implications for Industrial Sewing Operations

Single-needle sewing machines typically have lower initial costs and simpler maintenance requirements, making them a cost-effective choice for industrial operations focused on basic stitching tasks. Double-needle sewing machines, while more expensive upfront, increase productivity by enabling simultaneous dual stitching, reducing labor time and material waste in garment manufacturing. Factoring in variables like production volume and stitch complexity, double-needle sewing often delivers superior cost efficiency in large-scale industrial applications despite higher capital investment.

Suitability for Different Fabrics and Projects

Single-needle sewing offers precise stitching ideal for lightweight and delicate fabrics, making it suitable for tailored garments and detailed projects requiring fine seams. Double-needle sewing provides reinforced parallel stitching, enhancing durability on medium to heavy fabrics commonly used in denim, upholstery, and activewear. Choosing between single-needle and double-needle machines depends on fabric thickness and the project's need for strength versus subtlety in stitch appearance.

Maintenance and Durability Considerations

Single-needle sewing machines generally require less frequent maintenance due to simpler mechanics and fewer moving parts, enhancing long-term reliability. Double-needle machines, while offering greater stitch variety and strength, demand more regular upkeep to ensure alignment and tension are maintained for durability. Proper maintenance of needles, thread paths, and tension settings in both types is crucial to prevent fabric damage and extend the lifespan of sewing equipment and finished garments.

Choosing the Right Sewing Technique for Your Business

Single-needle sewing offers precision and control, ideal for detailed stitching and delicate fabrics, making it suitable for custom or high-end garment production. Double-needle sewing enhances efficiency and durability by creating parallel rows of stitches, perfect for mass production and reinforcing seams in apparel like denim and activewear. Selecting the right technique depends on your business goals, fabric types, and production volume to balance quality and speed effectively.

Single-needle sewing vs Double-needle sewing Infographic

bizdif.com

bizdif.com