A single-needle sewing machine offers precise stitching ideal for detailed pet clothing and small projects, providing greater control and customization. Multi-needle machines enhance efficiency by allowing multiple thread colors to be used simultaneously, perfect for complex embroidery designs on pet accessories. Choosing between the two depends on the balance between creative flexibility and production speed required for your sewing pet projects.

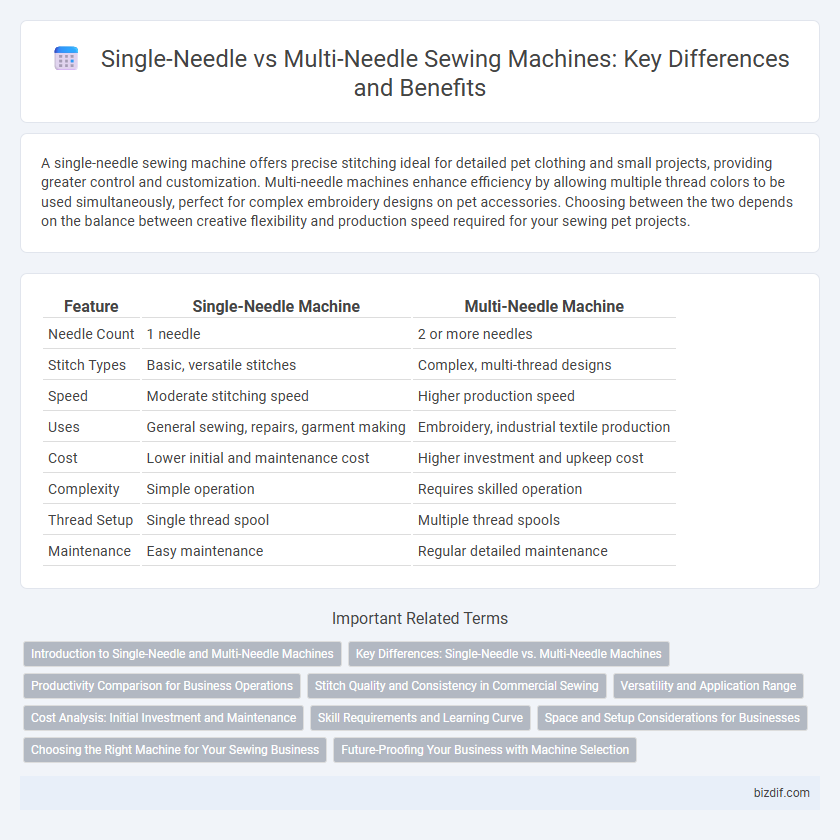

Table of Comparison

| Feature | Single-Needle Machine | Multi-Needle Machine |

|---|---|---|

| Needle Count | 1 needle | 2 or more needles |

| Stitch Types | Basic, versatile stitches | Complex, multi-thread designs |

| Speed | Moderate stitching speed | Higher production speed |

| Uses | General sewing, repairs, garment making | Embroidery, industrial textile production |

| Cost | Lower initial and maintenance cost | Higher investment and upkeep cost |

| Complexity | Simple operation | Requires skilled operation |

| Thread Setup | Single thread spool | Multiple thread spools |

| Maintenance | Easy maintenance | Regular detailed maintenance |

Introduction to Single-Needle and Multi-Needle Machines

Single-needle sewing machines feature one needle and are ideal for detailed stitching, garment construction, and general-purpose sewing with precision. Multi-needle machines integrate multiple needles, enabling simultaneous stitching of several threads, which significantly increases production speed in embroidery and complex pattern applications. Choosing between single-needle and multi-needle machines depends on the required stitching complexity, production volume, and fabric types.

Key Differences: Single-Needle vs. Multi-Needle Machines

Single-needle sewing machines use one needle to create precise, high-quality stitches, ideal for detailed work and garment construction. Multi-needle machines contain multiple needles working simultaneously to produce complex, multicolor embroidery patterns efficiently, boosting productivity in industrial settings. The choice depends on the project needs, with single-needle machines offering versatility and multi-needle machines excelling in speed and design complexity.

Productivity Comparison for Business Operations

Single-needle machines offer precise stitch control ideal for detailed garment work but operate at slower speeds, making them less efficient for high-volume production. Multi-needle machines enhance productivity by simultaneously stitching multiple colors or patterns, significantly reducing production time in mass manufacturing environments. Businesses looking to optimize throughput often prefer multi-needle machines for large-scale operations, as they deliver faster cycle times and consistent output with minimal manual intervention.

Stitch Quality and Consistency in Commercial Sewing

Single-needle machines deliver superior stitch quality with precise tension control, making them ideal for intricate and high-detail sewing tasks in commercial production. Multi-needle machines excel in consistency and speed, producing multiple needles' stitching simultaneously, which enhances uniformity across large batches of garments. The choice between these machines depends on the balance between high stitch precision and efficient mass production requirements.

Versatility and Application Range

Single-needle machines offer greater versatility for detailed stitching, making them ideal for intricate garment construction and custom tailoring. Multi-needle machines excel in high-volume embroidery production, enabling simultaneous stitching with multiple threads for complex patterns and color shifts. Choosing between single-needle and multi-needle machines depends on the specific application range, balancing precision work against mass embroidery efficiency.

Cost Analysis: Initial Investment and Maintenance

Single-needle sewing machines typically require a lower initial investment compared to multi-needle machines, making them more accessible for small businesses and hobbyists. Maintenance costs for single-needle machines are generally less expensive due to simpler mechanics and fewer parts needing replacement. Multi-needle machines, while costlier upfront, offer higher productivity and lower labor costs, potentially offsetting maintenance expenses over time in industrial or high-volume production settings.

Skill Requirements and Learning Curve

Single-needle sewing machines require less technical skill, making them ideal for beginners and simple stitching tasks, whereas multi-needle machines demand advanced proficiency due to their complexity and multiple thread management. Mastery of multi-needle machines involves understanding intricate threading systems and precise timing adjustments, resulting in a steeper learning curve. Efficient operation of multi-needle machines significantly enhances productivity in embroidery and garment manufacturing compared to single-needle machines.

Space and Setup Considerations for Businesses

Single-needle machines require less workspace and offer simpler setup processes, making them ideal for small-scale operations or businesses with limited floor space. Multi-needle machines demand more room due to their larger frames and multiple thread spools, but they significantly boost productivity by handling multiple threads simultaneously. Businesses must weigh space constraints against production volume to choose the optimal sewing machine setup that maximizes efficiency without overcrowding the workspace.

Choosing the Right Machine for Your Sewing Business

Selecting the right machine for your sewing business depends on production volume and project complexity, with single-needle machines offering precision for detailed work and multi-needle machines maximizing efficiency in mass production. Single-needle machines excel in custom tailoring and intricate stitching, while multi-needle machines enhance productivity in embroidery and large-scale garment manufacturing. Investing in a machine that aligns with your business goals ensures optimal workflow and cost-effectiveness.

Future-Proofing Your Business with Machine Selection

Choosing a multi-needle sewing machine enhances future-proofing by increasing production speed and enabling complex stitching designs that meet evolving market demands. Single-needle machines offer simplicity and precision, ideal for niche or customized products but may limit scalability and efficiency. Investing in advanced multi-needle technology ensures adaptability to trends, supports higher output, and maximizes return on investment for growing businesses.

Single-needle machine vs multi-needle machine Infographic

bizdif.com

bizdif.com