Chainstitch creates a flexible, decorative seam ideal for lightweight fabrics but tends to unravel easily, making it less durable for pet accessories. Lockstitch provides a strong, secure seam with interlocking threads on both sides, ensuring long-lasting durability for pet collars, harnesses, and clothing. Choosing lockstitch is preferable for pet sewing projects requiring strength and resistance to wear.

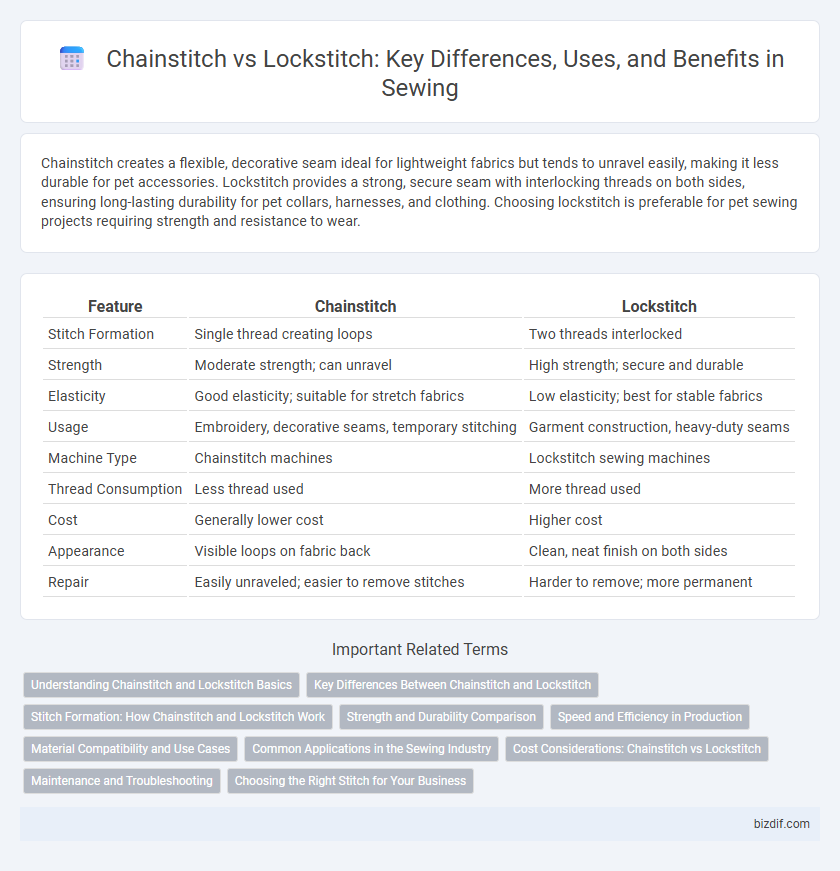

Table of Comparison

| Feature | Chainstitch | Lockstitch |

|---|---|---|

| Stitch Formation | Single thread creating loops | Two threads interlocked |

| Strength | Moderate strength; can unravel | High strength; secure and durable |

| Elasticity | Good elasticity; suitable for stretch fabrics | Low elasticity; best for stable fabrics |

| Usage | Embroidery, decorative seams, temporary stitching | Garment construction, heavy-duty seams |

| Machine Type | Chainstitch machines | Lockstitch sewing machines |

| Thread Consumption | Less thread used | More thread used |

| Cost | Generally lower cost | Higher cost |

| Appearance | Visible loops on fabric back | Clean, neat finish on both sides |

| Repair | Easily unraveled; easier to remove stitches | Harder to remove; more permanent |

Understanding Chainstitch and Lockstitch Basics

Chainstitch forms a series of looped stitches on the fabric's surface, creating a flexible seam ideal for lightweight materials and temporary stitching. Lockstitch uses two threads interlocked between fabric layers, offering strong, durable seams suitable for heavy-duty garments and long-lasting wear. Understanding these basic stitch types helps in selecting the right stitch for specific sewing projects based on fabric type and seam strength requirements.

Key Differences Between Chainstitch and Lockstitch

Chainstitch and lockstitch differ primarily in stitch structure and durability; chainstitch forms a series of looped stitches using a single thread, creating flexibility but prone to unraveling, while lockstitch uses two interlocking threads for a strong, secure seam. Chainstitch is faster and common in decorative or temporary stitches, whereas lockstitch offers superior strength, making it ideal for heavy-duty garments and seams requiring longevity. The choice between these stitches affects fabric compatibility, seam strength, and garment finish, impacting overall sewing project outcomes.

Stitch Formation: How Chainstitch and Lockstitch Work

Chainstitch forms a series of interlocking loops made by a single needle and thread, creating a flexible and stretchable seam often used in embroidery and temporary stitching. Lockstitch uses two threads--one from the needle and one from the bobbin--that interlock between the fabric layers, producing a strong, durable, and secure stitch ideal for most garment construction. The mechanical difference in stitch formation impacts seam strength, elasticity, and suitability for various fabric types and sewing purposes.

Strength and Durability Comparison

Chainstitch offers flexibility and faster sewing, but it lacks the strength and durability of lockstitch, which secures fabric layers with two interlocking threads. Lockstitch resists unraveling and withstands higher tension, making it ideal for heavy-duty materials and long-lasting seams. The choice between chainstitch and lockstitch significantly impacts garment lifespan, especially in demanding applications.

Speed and Efficiency in Production

Chainstitch machines generally operate faster than lockstitch machines, making them preferable for high-speed production environments. While chainstitch offers quicker stitching, lockstitch provides greater durability and security by interlocking threads, reducing the need for frequent rework and increasing overall efficiency. Balancing the speed of chainstitch with the reliability of lockstitch can optimize manufacturing throughput and minimize material waste.

Material Compatibility and Use Cases

Chainstitch machines excel with lightweight fabrics such as cotton and polyester, offering flexibility and stretch ideal for sportswear and casual garments. Lockstitch machines provide strong, secure seams compatible with a wide range of materials, including denim, leather, and heavy upholstery fabrics, making them preferred for high-stress or durable items. Textile manufacturers often select chainstitch for fast production of garments requiring elasticity, while lockstitch is favored in tailoring and upholstery where seam strength and longevity are critical.

Common Applications in the Sewing Industry

Chainstitch is commonly used in garment construction for its flexibility and cost-effectiveness, especially in t-shirt and denim production where stretchability is essential. Lockstitch dominates applications requiring durability and strength, such as upholstery, jeans, and heavy-duty workwear, due to its secured stitch that resists unraveling. Industrial sewing machines for lockstitch are preferred in manufacturing high-quality, long-lasting textile products, while chainstitch is favored for faster production and ease of repair.

Cost Considerations: Chainstitch vs Lockstitch

Chainstitch machines typically have lower upfront costs and simpler maintenance requirements, making them more budget-friendly for small-scale or temporary sewing projects. Lockstitch machines, while generally more expensive initially, provide stronger, more durable seams that reduce long-term repair and replacement expenses. Investing in lockstitch technology often leads to greater cost efficiency in high-volume or heavy-duty applications due to enhanced stitch stability and fabric integrity.

Maintenance and Troubleshooting

Chainstitch machines require frequent tension adjustment and regular oiling to prevent thread looping and skipped stitches, while lockstitch machines benefit from consistent lint removal and timely needle replacement to avoid thread breakage and fabric puckering. Troubleshooting chainstitch issues often involves rethreading the loopers and checking for thread snarls, whereas lockstitch problems commonly stem from improper bobbin placement or needle compatibility. Maintaining both stitch types ensures optimal stitch quality and extends machine lifespan in industrial and home sewing environments.

Choosing the Right Stitch for Your Business

Choosing the right stitch for your sewing business depends on the intended product durability and fabric type, with lockstitch offering strong, secure seams ideal for garments requiring high tensile strength. Chainstitch provides flexibility and a decorative finish, making it suitable for knitwear and items needing stretch. Evaluate production speed, seam strength, and fabric compatibility to optimize efficiency and product quality in your business operations.

Chainstitch vs lockstitch Infographic

bizdif.com

bizdif.com