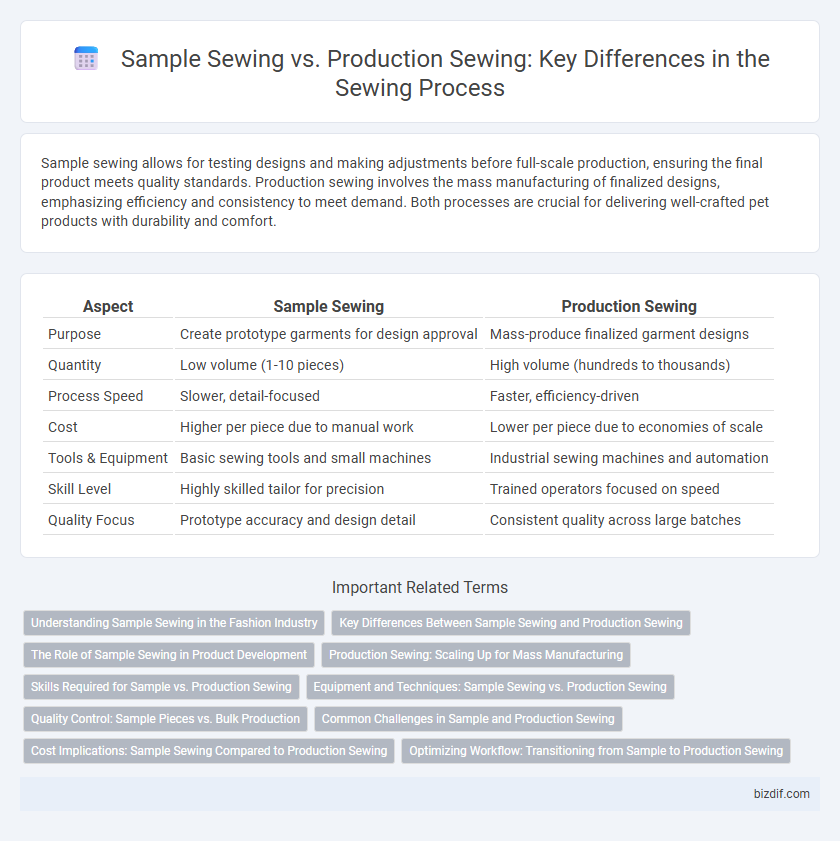

Sample sewing allows for testing designs and making adjustments before full-scale production, ensuring the final product meets quality standards. Production sewing involves the mass manufacturing of finalized designs, emphasizing efficiency and consistency to meet demand. Both processes are crucial for delivering well-crafted pet products with durability and comfort.

Table of Comparison

| Aspect | Sample Sewing | Production Sewing |

|---|---|---|

| Purpose | Create prototype garments for design approval | Mass-produce finalized garment designs |

| Quantity | Low volume (1-10 pieces) | High volume (hundreds to thousands) |

| Process Speed | Slower, detail-focused | Faster, efficiency-driven |

| Cost | Higher per piece due to manual work | Lower per piece due to economies of scale |

| Tools & Equipment | Basic sewing tools and small machines | Industrial sewing machines and automation |

| Skill Level | Highly skilled tailor for precision | Trained operators focused on speed |

| Quality Focus | Prototype accuracy and design detail | Consistent quality across large batches |

Understanding Sample Sewing in the Fashion Industry

Sample sewing in the fashion industry involves creating prototype garments to test design concepts, fabric choices, and construction techniques before mass production. This stage allows designers and manufacturers to identify and resolve fitting issues, assess aesthetic appeal, and refine patterns to ensure high-quality final products. Accurate sample sewing directly influences production efficiency, cost management, and the overall success of a fashion collection.

Key Differences Between Sample Sewing and Production Sewing

Sample sewing involves creating prototype garments to test design, fit, and construction details, often requiring meticulous handwork and custom adjustments. Production sewing focuses on mass-producing garments with consistent quality and efficiency using streamlined processes and industrial machinery. Key differences include the level of customization, scale of output, and emphasis on precision versus speed.

The Role of Sample Sewing in Product Development

Sample sewing plays a crucial role in product development by allowing designers and manufacturers to test patterns, fabrics, and construction techniques before mass production. It helps identify potential issues in fit, functionality, and aesthetics, ensuring the final garment meets quality standards and design specifications. Effective sample sewing reduces costly errors and streamlines the production sewing process, leading to improved efficiency and product consistency.

Production Sewing: Scaling Up for Mass Manufacturing

Production sewing involves scaling up garment assembly processes to meet high-volume demand, focusing on efficiency, consistency, and speed. Techniques include automated stitching, standardized patterns, and quality control systems to ensure uniformity across thousands of units. This phase demands robust machinery, skilled operators, and optimized workflows to maintain production deadlines and cost-effectiveness in mass manufacturing.

Skills Required for Sample vs. Production Sewing

Sample sewing demands advanced skills in pattern manipulation, precise fitting adjustments, and creative problem-solving to create prototypes that align with design specifications. Production sewing requires consistent speed, accuracy, and the ability to operate industrial machines efficiently to maintain high-volume output with uniform quality. Mastery of complex technical techniques is essential for sample sewing, while production sewing prioritizes specialization and repetitive task proficiency.

Equipment and Techniques: Sample Sewing vs. Production Sewing

Sample sewing employs versatile, manual equipment such as sewing machines with adjustable settings to accommodate design changes and custom details, focusing on precision and adaptability. Production sewing utilizes high-speed, automated machinery designed for consistency, efficiency, and repeatability in mass manufacturing environments. Techniques in sample sewing emphasize craftsmanship and iteration, while production sewing prioritizes streamlined processes and standardized operations to meet large-scale output demands.

Quality Control: Sample Pieces vs. Bulk Production

Sample sewing involves meticulous quality control to ensure each piece meets design specifications before mass production, focusing on precision and detail. In production sewing, quality control shifts to monitoring consistency across large quantities, employing statistical sampling and process checks to maintain product standards. Effective QC strategies bridge the gap between the initial sample's craftsmanship and the uniformity required in bulk manufacturing.

Common Challenges in Sample and Production Sewing

Sample sewing faces challenges such as frequent design changes, limited fabric availability, and tight deadlines that demand precision and rapid adjustments. Production sewing encounters issues with maintaining consistent quality across large volumes, equipment downtime, and workforce skill variability. Both stages require effective communication and quality control to ensure the final garment meets design specifications and customer expectations.

Cost Implications: Sample Sewing Compared to Production Sewing

Sample sewing involves higher per-unit costs due to small batch sizes, intricate customization, and frequent adjustments that require skilled labor and more time. Production sewing benefits from economies of scale, automated processes, and streamlined workflows, significantly reducing the cost per garment. Understanding these cost implications is crucial for budgeting and pricing in fashion manufacturing.

Optimizing Workflow: Transitioning from Sample to Production Sewing

Optimizing workflow when transitioning from sample sewing to production sewing involves standardizing patterns and establishing consistent stitching techniques to ensure scalability and efficiency. Implementing quality control checkpoints during production sewing reduces errors and maintains the integrity of the initial sample design. Leveraging digital tools to track fabric usage and machine performance can streamline the shift from small-scale sample runs to high-volume production.

Sample sewing vs Production sewing Infographic

bizdif.com

bizdif.com