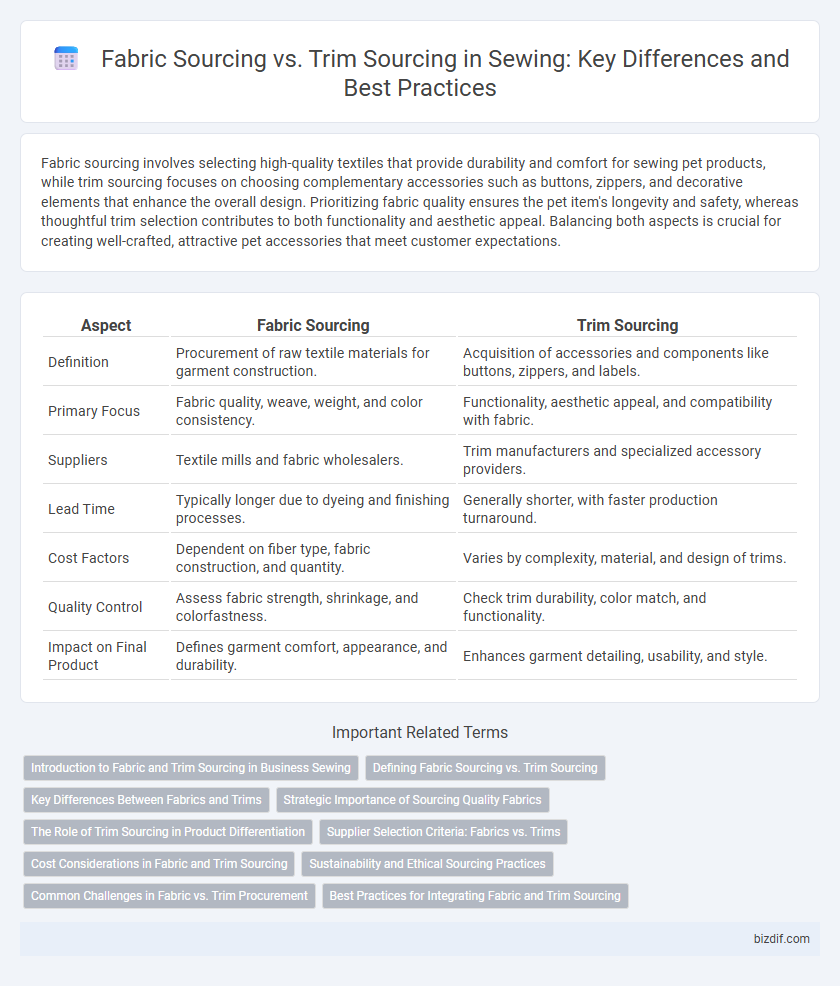

Fabric sourcing involves selecting high-quality textiles that provide durability and comfort for sewing pet products, while trim sourcing focuses on choosing complementary accessories such as buttons, zippers, and decorative elements that enhance the overall design. Prioritizing fabric quality ensures the pet item's longevity and safety, whereas thoughtful trim selection contributes to both functionality and aesthetic appeal. Balancing both aspects is crucial for creating well-crafted, attractive pet accessories that meet customer expectations.

Table of Comparison

| Aspect | Fabric Sourcing | Trim Sourcing |

|---|---|---|

| Definition | Procurement of raw textile materials for garment construction. | Acquisition of accessories and components like buttons, zippers, and labels. |

| Primary Focus | Fabric quality, weave, weight, and color consistency. | Functionality, aesthetic appeal, and compatibility with fabric. |

| Suppliers | Textile mills and fabric wholesalers. | Trim manufacturers and specialized accessory providers. |

| Lead Time | Typically longer due to dyeing and finishing processes. | Generally shorter, with faster production turnaround. |

| Cost Factors | Dependent on fiber type, fabric construction, and quantity. | Varies by complexity, material, and design of trims. |

| Quality Control | Assess fabric strength, shrinkage, and colorfastness. | Check trim durability, color match, and functionality. |

| Impact on Final Product | Defines garment comfort, appearance, and durability. | Enhances garment detailing, usability, and style. |

Introduction to Fabric and Trim Sourcing in Business Sewing

Fabric sourcing involves procuring textiles that meet specific quality, texture, and durability requirements essential for garment production, while trim sourcing focuses on acquiring complementary materials such as buttons, zippers, and ribbons that enhance the garment's functionality and aesthetic appeal. Both fabric and trim sourcing require careful evaluation of supplier reliability, cost efficiency, and lead times to maintain production schedules and product standards. Efficient integration of fabric and trim sourcing strategies optimizes inventory management and contributes significantly to the overall success of business sewing operations.

Defining Fabric Sourcing vs. Trim Sourcing

Fabric sourcing involves procuring the primary textile materials used to create garments or other sewn products, focusing on qualities like fiber content, weave, weight, and colorfastness. Trim sourcing refers to acquiring supplementary components such as buttons, zippers, threads, labels, and embellishments that enhance functionality and aesthetics. Understanding the distinction is critical for efficient supply chain management, ensuring timely availability and compatibility of both fabric and trims in the production process.

Key Differences Between Fabrics and Trims

Fabric sourcing involves obtaining the primary textile materials essential for garment construction, focusing on qualities like fiber content, weave, durability, and color fastness. Trim sourcing deals with supplementary components such as zippers, buttons, labels, and decorative elements, emphasizing functionality, aesthetics, and compatibility with the fabric. The key differences lie in the material type, sourcing complexity, and impact on the garment's overall design and performance.

Strategic Importance of Sourcing Quality Fabrics

Sourcing quality fabrics is crucial for ensuring garment durability, comfort, and aesthetic appeal, directly impacting brand reputation and customer satisfaction. While trim sourcing contributes to garment detailing, the strategic focus on fabric quality drives overall product performance and influences manufacturing efficiency. Investing in high-quality fabrics reduces production defects and supports sustainability initiatives by promoting long-lasting apparel.

The Role of Trim Sourcing in Product Differentiation

Trim sourcing plays a crucial role in product differentiation by adding unique aesthetic and functional elements that enhance the overall garment design. Unlike fabric sourcing, which provides the base material, trim sourcing involves selecting buttons, zippers, labels, and decorative accents that create distinctive brand identity and elevate the product's appeal. Strategic trim choices can influence consumer perception, increase market value, and set a garment apart in a competitive fashion industry.

Supplier Selection Criteria: Fabrics vs. Trims

Supplier selection criteria for fabric sourcing emphasize material quality, fiber composition, fabric weight, and durability to ensure optimal garment performance. Trim sourcing prioritizes precision in color matching, component compatibility, and production lead time to maintain design integrity and assembly efficiency. Both processes require rigorous supplier reliability assessment and compliance with sustainability standards for consistent, high-quality garment production.

Cost Considerations in Fabric and Trim Sourcing

Fabric sourcing generally involves higher cost considerations due to the bulk volume and material complexity, directly impacting production budgets. Trim sourcing, while typically lower in raw material cost, can incur additional expenses from specialized finishes and custom components. Efficient cost management requires balancing fabric quality with trim detail to optimize overall garment expenditure.

Sustainability and Ethical Sourcing Practices

Fabric sourcing demands rigorous sustainability standards involving organic or recycled textiles that minimize environmental impact and reduce carbon footprint. Trim sourcing emphasizes ethical practices by selecting suppliers committed to fair labor conditions, non-toxic materials, and transparent supply chains. Integrating sustainable fabrics with responsibly sourced trims ensures a holistic approach to environmentally friendly and socially responsible garment production.

Common Challenges in Fabric vs. Trim Procurement

Fabric sourcing often faces challenges related to variability in material quality, longer lead times, and higher minimum order quantities due to the complexity of textile production. Trim procurement, on the other hand, struggles with ensuring color consistency, coordinating with multiple small suppliers, and managing diverse product specifications such as zippers, buttons, and labels. Both processes require careful inventory management and supplier reliability to maintain production schedules and meet design requirements.

Best Practices for Integrating Fabric and Trim Sourcing

Efficient integration of fabric and trim sourcing requires aligning suppliers' lead times and quality standards to ensure cohesive production schedules and consistent product performance. Establishing clear communication channels and centralized procurement systems helps synchronize fabric and trim inventories, reducing delays and minimizing waste. Leveraging technology for real-time tracking and vendor collaboration enhances transparency, enabling proactive adjustments and cost optimization across the supply chain.

Fabric sourcing vs Trim sourcing Infographic

bizdif.com

bizdif.com