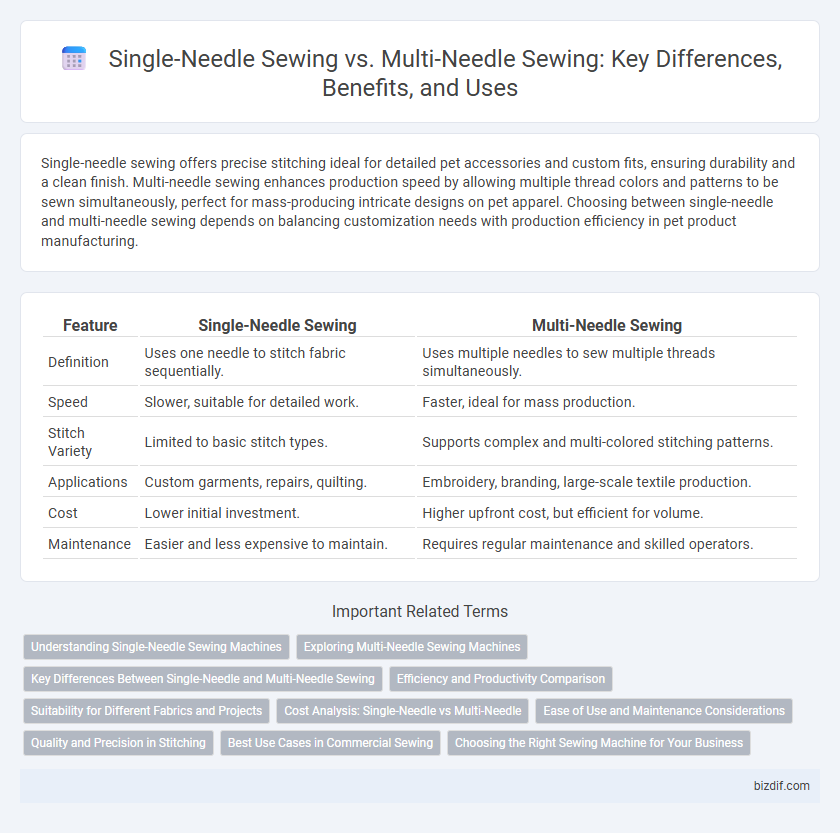

Single-needle sewing offers precise stitching ideal for detailed pet accessories and custom fits, ensuring durability and a clean finish. Multi-needle sewing enhances production speed by allowing multiple thread colors and patterns to be sewn simultaneously, perfect for mass-producing intricate designs on pet apparel. Choosing between single-needle and multi-needle sewing depends on balancing customization needs with production efficiency in pet product manufacturing.

Table of Comparison

| Feature | Single-Needle Sewing | Multi-Needle Sewing |

|---|---|---|

| Definition | Uses one needle to stitch fabric sequentially. | Uses multiple needles to sew multiple threads simultaneously. |

| Speed | Slower, suitable for detailed work. | Faster, ideal for mass production. |

| Stitch Variety | Limited to basic stitch types. | Supports complex and multi-colored stitching patterns. |

| Applications | Custom garments, repairs, quilting. | Embroidery, branding, large-scale textile production. |

| Cost | Lower initial investment. | Higher upfront cost, but efficient for volume. |

| Maintenance | Easier and less expensive to maintain. | Requires regular maintenance and skilled operators. |

Understanding Single-Needle Sewing Machines

Single-needle sewing machines use one needle to create precise, high-quality stitches ideal for detailed garment construction and intricate designs. These machines provide greater control over fabric handling and stitch accuracy, making them essential for tailored clothing and delicate fabrics. Single-needle machines are also easier to maintain and adjust, enhancing efficiency for custom sewing projects and small-scale production.

Exploring Multi-Needle Sewing Machines

Multi-needle sewing machines enhance production efficiency by allowing multiple threads to stitch simultaneously, reducing time on complex or multi-colored designs. These machines are ideal for embroidery, enabling intricate patterns with precision and consistency across large volumes. Their ability to automatically switch needles streamlines workflow and improves overall garment quality in industrial sewing environments.

Key Differences Between Single-Needle and Multi-Needle Sewing

Single-needle sewing uses one needle to create precise, detailed stitches, ideal for custom tailoring and repair work. Multi-needle sewing machines feature multiple needles that can sew several colors or threads simultaneously, increasing efficiency in mass production. The primary differences lie in the speed, stitch complexity, and suitability for either detailed or large-scale garment manufacturing.

Efficiency and Productivity Comparison

Single-needle sewing offers precise control and is ideal for detailed, custom work but generally operates at a slower pace, limiting overall productivity for high-volume tasks. Multi-needle sewing machines streamline production by simultaneously stitching multiple threads, significantly increasing sewing speed and efficiency in mass manufacturing environments. The choice between single-needle and multi-needle sewing hinges on balancing precision requirements with the need for high throughput in apparel or textile production.

Suitability for Different Fabrics and Projects

Single-needle sewing offers precise stitching ideal for lightweight and delicate fabrics like silk, chiffon, and fine cotton, making it suitable for tailored garments and detailed finishing projects. Multi-needle sewing excels with heavy fabrics such as denim, canvas, and upholstery materials, providing efficient high-speed stitching for large-scale production and repetitive tasks like jeans or upholstery covers. Each method's suitability depends on fabric thickness, project complexity, and production volume requirements.

Cost Analysis: Single-Needle vs Multi-Needle

Single-needle sewing machines have a lower upfront cost but may increase labor expenses due to slower production speeds and manual thread changes. Multi-needle machines, while requiring higher initial investment, reduce labor costs by automating multiple thread functions and boosting efficiency. Evaluating total cost of ownership involves balancing machine price against productivity gains and maintenance expenses for optimal sewing operations.

Ease of Use and Maintenance Considerations

Single-needle sewing machines offer greater ease of use due to their simpler mechanics, making them ideal for beginners and straightforward garment construction. Multi-needle sewing machines require more maintenance because of their complex mechanisms and multiple needles, which can increase downtime and the need for professional servicing. Choosing between the two depends on balancing operational simplicity with production efficiency and maintenance capabilities.

Quality and Precision in Stitching

Single-needle sewing delivers superior quality and precision by allowing greater control over each stitch, resulting in finely detailed and consistent seams ideal for delicate fabrics. Multi-needle sewing enhances production speed but may compromise stitch accuracy due to simultaneous needle operation, leading to slight variations in tension and alignment. Choosing between single-needle and multi-needle sewing depends on the required stitch quality, with single-needle preferred for high-precision garments and multi-needle suited for mass production.

Best Use Cases in Commercial Sewing

Single-needle sewing machines excel in precision stitching for detailed garment construction and high-quality finishes, ideal for tailored apparel and delicate fabrics. Multi-needle sewing machines enhance production efficiency by simultaneously creating multiple parallel stitches, making them perfect for large-scale manufacturing of denim, sportswear, and upholstery. Commercial sewing operations benefit from selecting based on fabric type and production volume to optimize speed and stitch consistency.

Choosing the Right Sewing Machine for Your Business

Single-needle sewing machines excel in precision and are ideal for detailed, high-quality stitching on lightweight fabrics, making them perfect for small-scale or specialized garment production. Multi-needle sewing machines increase efficiency by allowing multiple thread colors or stitches to be applied simultaneously, enhancing productivity in large-scale manufacturing environments. Selecting the right machine depends on your business needs, fabric types, and production volume, ensuring optimal balance between speed, versatility, and stitch quality.

Single-needle sewing vs Multi-needle sewing Infographic

bizdif.com

bizdif.com