Custom sewing for pets offers tailored fits and unique designs that cater to individual needs, ensuring comfort and style. Mass sewing focuses on producing large quantities with standardized sizes, often sacrificing personalization for efficiency. Choosing custom sewing provides higher quality and attention to detail compared to the uniform approach of mass sewing.

Table of Comparison

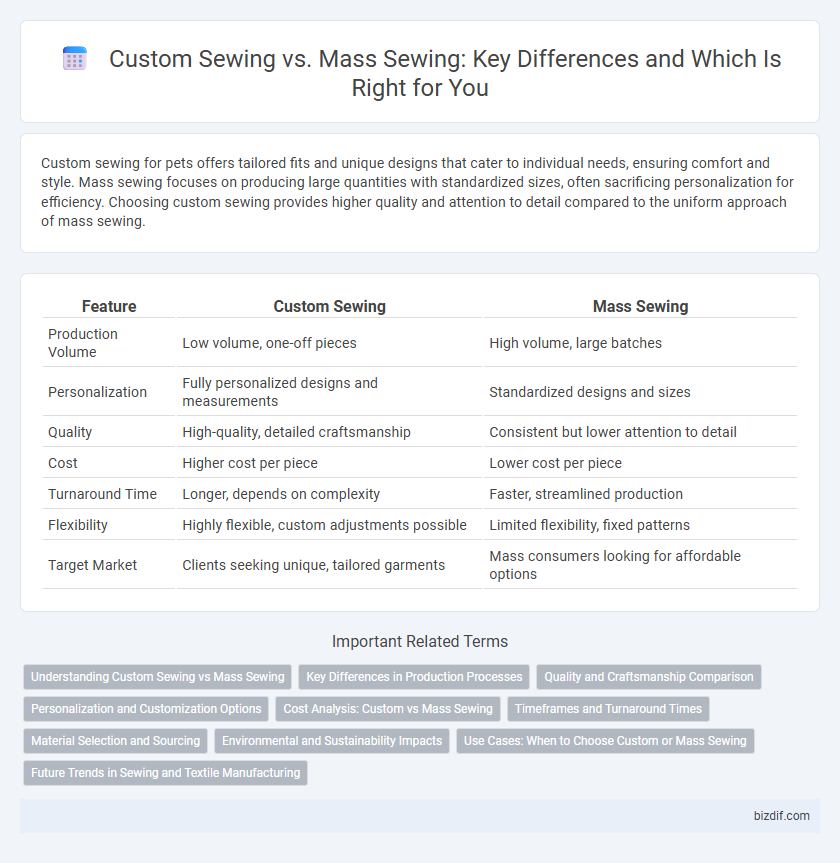

| Feature | Custom Sewing | Mass Sewing |

|---|---|---|

| Production Volume | Low volume, one-off pieces | High volume, large batches |

| Personalization | Fully personalized designs and measurements | Standardized designs and sizes |

| Quality | High-quality, detailed craftsmanship | Consistent but lower attention to detail |

| Cost | Higher cost per piece | Lower cost per piece |

| Turnaround Time | Longer, depends on complexity | Faster, streamlined production |

| Flexibility | Highly flexible, custom adjustments possible | Limited flexibility, fixed patterns |

| Target Market | Clients seeking unique, tailored garments | Mass consumers looking for affordable options |

Understanding Custom Sewing vs Mass Sewing

Custom sewing involves crafting garments tailored specifically to individual measurements and preferences, ensuring unique fit and personalized details. Mass sewing relies on standardized sizes and assembly-line production techniques to create large quantities of identical clothing quickly and cost-effectively. Understanding the distinctions between custom sewing and mass sewing highlights the trade-offs between personalization and efficiency in garment manufacturing.

Key Differences in Production Processes

Custom sewing involves handcrafted techniques tailored to individual measurements and preferences, resulting in unique, high-quality garments made in small batches. Mass sewing utilizes automated machinery and standardized patterns to produce large quantities of identical items quickly and cost-effectively. The key difference lies in the balance between personalization and efficiency, with custom sewing prioritizing detail and fit, while mass sewing emphasizes volume and uniformity.

Quality and Craftsmanship Comparison

Custom sewing emphasizes superior quality and craftsmanship by offering meticulous attention to detail, precise measurements, and personalized fabric choices that ensure a perfect fit and durability. In contrast, mass sewing prioritizes efficiency and volume, often sacrificing intricate handiwork and unique tailoring to meet large-scale production demands. The bespoke nature of custom sewing results in garments that exhibit refined finishes and longevity, distinguishing them from the more uniform and quickly produced items in mass sewing.

Personalization and Customization Options

Custom sewing offers unparalleled personalization and customization options, allowing clients to choose specific fabrics, patterns, and measurements tailored to their unique preferences. Mass sewing prioritizes efficiency and uniformity, producing standardized garments with limited scope for individual adjustments. The emphasis on bespoke design in custom sewing enhances fit, style, and exclusivity compared to the one-size-fits-all approach typical in mass production.

Cost Analysis: Custom vs Mass Sewing

Custom sewing typically incurs higher costs due to personalized design, skilled labor, and smaller production runs, which increase time and material expenses. Mass sewing benefits from economies of scale, reducing unit costs through bulk purchasing, automated processes, and standardized patterns. Analyzing cost factors reveals that while custom sewing offers unique, tailored products, mass sewing remains more cost-effective for large-volume production.

Timeframes and Turnaround Times

Custom sewing typically requires longer timeframes due to the detailed handcrafting and individual measurements involved, often taking several days to weeks for completion. Mass sewing, driven by industrial machines and assembly lines, significantly reduces turnaround times, enabling bulk production in hours to a few days. The trade-off between these methods is precision and personalization versus speed and volume efficiency.

Material Selection and Sourcing

Custom sewing prioritizes high-quality, unique materials tailored to specific client needs, often sourcing premium fabrics from specialized suppliers to ensure exclusivity and durability. Mass sewing relies on bulk purchasing of standardized materials from large-scale manufacturers, focusing on cost-efficiency and consistent supply to meet high production volumes. Material selection in custom sewing enhances product uniqueness and value, while mass sewing emphasizes uniformity and scalability.

Environmental and Sustainability Impacts

Custom sewing significantly reduces fabric waste and energy consumption compared to mass sewing by producing tailored garments on demand, minimizing overproduction and unsold inventory. Mass sewing often relies on synthetic materials and large-scale manufacturing processes that contribute to higher carbon emissions and water pollution. Emphasizing custom sewing supports sustainable fashion practices through efficient resource use and decreased environmental impact.

Use Cases: When to Choose Custom or Mass Sewing

Choose custom sewing for unique designs, tailored fits, and special fabrics requiring detailed craftsmanship, ideal for bespoke garments, costumes, and limited-edition collections. Mass sewing suits large-scale production with consistent quality, cost efficiency, and faster turnaround times, perfect for retail apparel, uniforms, and standard-size clothing lines. Evaluating project volume, design complexity, and budget helps determine whether custom or mass sewing best meets specific garment production needs.

Future Trends in Sewing and Textile Manufacturing

Custom sewing leverages advanced digital tools and AI-driven pattern design to meet increasing demand for personalized apparel, reflecting a shift toward sustainable, made-to-order fashion. Mass sewing evolves through automation and robotics, optimizing efficiency and reducing production costs while integrating smart textiles and IoT-enabled quality control systems. Future trends highlight a convergence of customization and mass production, driven by AI, 3D knitting technologies, and sustainable materials, transforming textile manufacturing into a more agile and eco-conscious industry.

Custom Sewing vs Mass Sewing Infographic

bizdif.com

bizdif.com