Sourcing agents offer expertise and local market knowledge, simplifying the procurement process for sewing pet products by managing supplier relationships and quality control. Direct sourcing provides greater control over production, often reducing costs and lead times but requires more hands-on management and stronger supplier vetting. Choosing between sourcing agents and direct sourcing depends on a business's scale, resources, and need for control in pet sewing material procurement.

Table of Comparison

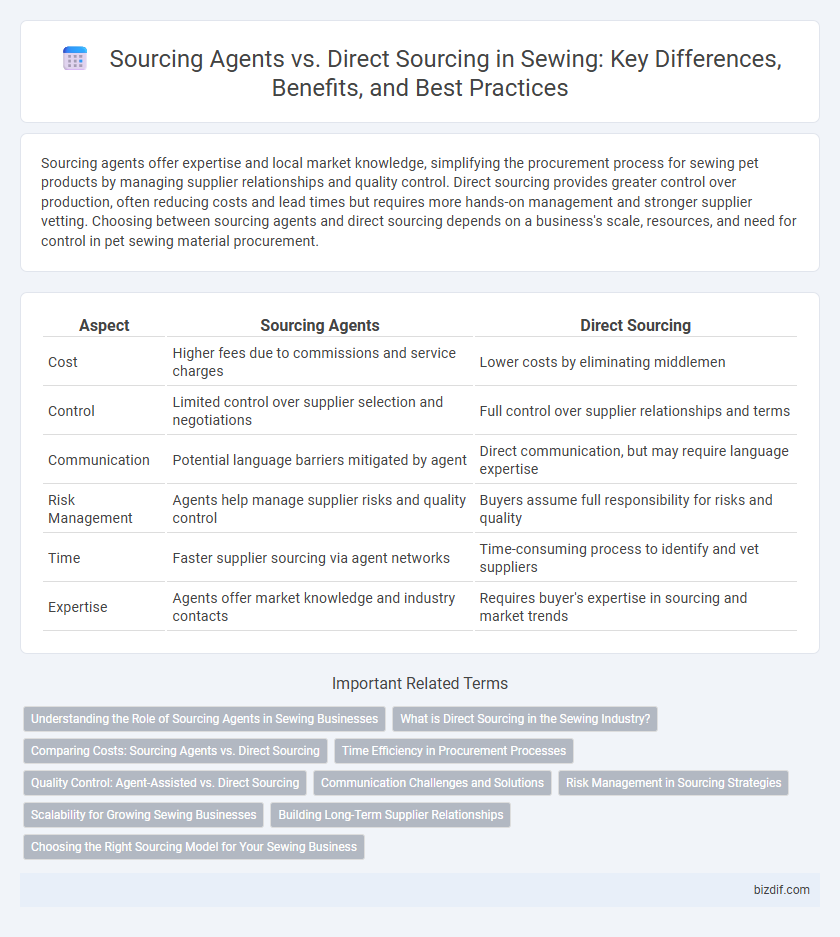

| Aspect | Sourcing Agents | Direct Sourcing |

|---|---|---|

| Cost | Higher fees due to commissions and service charges | Lower costs by eliminating middlemen |

| Control | Limited control over supplier selection and negotiations | Full control over supplier relationships and terms |

| Communication | Potential language barriers mitigated by agent | Direct communication, but may require language expertise |

| Risk Management | Agents help manage supplier risks and quality control | Buyers assume full responsibility for risks and quality |

| Time | Faster supplier sourcing via agent networks | Time-consuming process to identify and vet suppliers |

| Expertise | Agents offer market knowledge and industry contacts | Requires buyer's expertise in sourcing and market trends |

Understanding the Role of Sourcing Agents in Sewing Businesses

Sourcing agents in sewing businesses streamline procurement by connecting manufacturers with reliable fabric suppliers, ensuring quality control and cost-efficiency. They navigate complex international supply chains, manage negotiations, and handle logistics, which reduces risks and saves time for companies. Direct sourcing requires deeper industry knowledge and stronger supplier relationships but offers greater control over material selection and pricing without intermediary fees.

What is Direct Sourcing in the Sewing Industry?

Direct sourcing in the sewing industry involves businesses working directly with manufacturers or garment factories to procure materials and production services without intermediaries. This approach enables better control over quality, reduces costs, and shortens lead times compared to using sourcing agents. Manufacturers benefit from direct communication, streamlined processes, and enhanced customization options for garment production.

Comparing Costs: Sourcing Agents vs. Direct Sourcing

Sourcing agents typically add a service fee that increases overall production costs, while direct sourcing eliminates middlemen fees but requires more investment in supplier management and quality control. Direct sourcing often involves higher upfront costs for visits, negotiations, and samples, yet it can lead to lower per-unit prices as relationships with manufacturers strengthen. Companies must weigh the balance between agent fees and the operational costs of managing direct supplier interactions to optimize total sourcing expenses.

Time Efficiency in Procurement Processes

Sourcing agents streamline procurement by leveraging established supplier networks, reducing vendor search time and accelerating order placement. Direct sourcing often involves extended negotiation and validation periods, impacting overall time efficiency in sewing material acquisition. Efficient procurement balances speed with supplier reliability to minimize production delays.

Quality Control: Agent-Assisted vs. Direct Sourcing

Agent-assisted sourcing provides a layer of quality control through intermediaries who conduct factory inspections and manage compliance checks, ensuring adherence to specified standards. Direct sourcing offers greater control and transparency by allowing buyers to interact with manufacturers firsthand, facilitating real-time monitoring of production quality and immediate corrective actions. Ultimately, the choice impacts defect rates, inspection accuracy, and overall garment quality consistency in the production process.

Communication Challenges and Solutions

Sourcing agents often act as intermediaries, which can lead to miscommunication and delays in relaying technical specifications and order updates between brands and manufacturers. Direct sourcing facilitates clearer communication by enabling direct dialogue, reducing misunderstandings and speeding up decision-making processes. Implementing digital collaboration tools and establishing clear communication protocols are effective solutions to overcome challenges in both sourcing models.

Risk Management in Sourcing Strategies

Sourcing agents mitigate risks by providing expertise in supplier vetting, quality control, and local market navigation, reducing the likelihood of miscommunication and production delays. Direct sourcing offers greater control over the supply chain, allowing for quicker response to quality issues and enhanced transparency but requires significant investment in relationship management and on-the-ground presence. Effective risk management in sourcing strategies balances the agility of direct sourcing with the specialized support of sourcing agents to optimize cost, quality, and reliability in garment manufacturing.

Scalability for Growing Sewing Businesses

Sourcing agents simplify scalability by managing supplier relationships and overseeing production logistics, allowing growing sewing businesses to focus on expansion without extensive in-house resources. Direct sourcing offers greater control and potentially lower costs but demands significant time and expertise to scale efficiently. Businesses aiming for rapid growth often balance both strategies to optimize supply chain flexibility and production capacity.

Building Long-Term Supplier Relationships

Sourcing agents act as intermediaries who facilitate initial connections and negotiations with suppliers, helping companies quickly access diverse manufacturing options. Direct sourcing involves establishing a direct relationship with manufacturers, fostering deeper collaboration, clearer communication, and stronger trust. Long-term supplier relationships are more sustainable and efficient through direct sourcing, enabling better quality control, innovation, and cost management in sewing production.

Choosing the Right Sourcing Model for Your Sewing Business

Choosing the right sourcing model for your sewing business hinges on factors like product complexity, order volume, and cost control. Sourcing agents offer expertise in supplier negotiation and quality assurance, reducing risks but adding intermediary fees. Direct sourcing grants greater control over manufacturing and often lowers costs but requires more hands-on management and industry connections.

Sourcing agents vs Direct sourcing Infographic

bizdif.com

bizdif.com