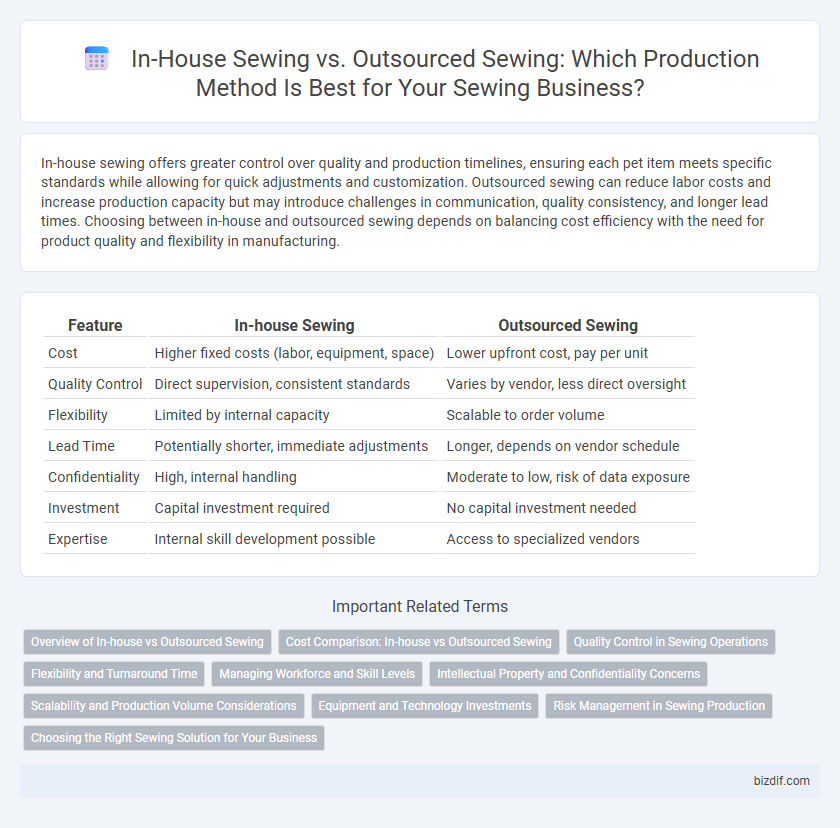

In-house sewing offers greater control over quality and production timelines, ensuring each pet item meets specific standards while allowing for quick adjustments and customization. Outsourced sewing can reduce labor costs and increase production capacity but may introduce challenges in communication, quality consistency, and longer lead times. Choosing between in-house and outsourced sewing depends on balancing cost efficiency with the need for product quality and flexibility in manufacturing.

Table of Comparison

| Feature | In-house Sewing | Outsourced Sewing |

|---|---|---|

| Cost | Higher fixed costs (labor, equipment, space) | Lower upfront cost, pay per unit |

| Quality Control | Direct supervision, consistent standards | Varies by vendor, less direct oversight |

| Flexibility | Limited by internal capacity | Scalable to order volume |

| Lead Time | Potentially shorter, immediate adjustments | Longer, depends on vendor schedule |

| Confidentiality | High, internal handling | Moderate to low, risk of data exposure |

| Investment | Capital investment required | No capital investment needed |

| Expertise | Internal skill development possible | Access to specialized vendors |

Overview of In-house vs Outsourced Sewing

In-house sewing offers greater control over quality, production speed, and customization due to direct management of skilled labor and equipment, facilitating rapid adjustments and prototyping. Outsourced sewing can reduce operational costs and increase scalability by leveraging specialized factories with lower labor expenses and established supply chains, though it may introduce challenges in quality consistency and communication. Choosing between in-house and outsourced sewing depends on factors such as production volume, budget constraints, and desired flexibility in manufacturing processes.

Cost Comparison: In-house vs Outsourced Sewing

In-house sewing demands significant upfront investment in equipment, skilled labor, and facility maintenance, driving higher fixed costs but offering greater control over quality and timelines. Outsourced sewing typically reduces cost per unit due to economies of scale and specialized labor pools, yet may incur variable expenses like shipping, customs, and quality assurance. Comparing these factors, businesses must balance fixed versus variable costs, production volume, and operational flexibility to determine the most cost-effective sewing strategy.

Quality Control in Sewing Operations

In-house sewing offers superior quality control by allowing direct oversight of every stitching process, ensuring consistent craftsmanship and the immediate correction of defects. Outsourced sewing often faces challenges in maintaining uniform quality due to limited visibility into the production line and reliance on third-party standards. Implementing rigorous quality checkpoints in in-house operations reduces errors and enhances product reliability compared to outsourcing sewing tasks.

Flexibility and Turnaround Time

In-house sewing offers greater flexibility for last-minute design changes and quick adjustments, enabling faster turnaround times tailored to specific project needs. Outsourced sewing may have longer lead times due to external scheduling constraints but can handle larger volumes efficiently. Balancing in-house agility with outsourced capacity optimizes production speed and responsiveness in garment manufacturing.

Managing Workforce and Skill Levels

In-house sewing allows for direct control over workforce training and skill development, ensuring consistent quality and quicker adaptation to production changes. Outsourced sewing often relies on external vendors with specialized skills but can pose challenges in maintaining uniform quality standards and coordinating communication. Effective workforce management requires balancing the benefits of hands-on supervision with the flexibility and expertise that outsourcing can offer.

Intellectual Property and Confidentiality Concerns

In-house sewing allows brands to maintain strict control over intellectual property and confidentiality, minimizing risks of design leaks and unauthorized reproductions. Outsourced sewing often involves sharing sensitive patterns and prototypes with third-party manufacturers, increasing vulnerability to intellectual property theft. Implementing robust non-disclosure agreements and selecting trusted partners are critical to safeguarding proprietary designs when outsourcing sewing operations.

Scalability and Production Volume Considerations

In-house sewing offers greater control over production quality and flexibility but may face limitations in scaling up quickly due to fixed labor and equipment capacity. Outsourced sewing facilitates handling larger production volumes efficiently by leveraging specialized factories with advanced machinery and skilled labor pools. Evaluating scalability involves balancing lead times, cost per unit, and potential bottlenecks linked to each production method's capacity constraints.

Equipment and Technology Investments

In-house sewing requires significant investment in advanced sewing machines, specialized cutting equipment, and technology-enabled workflows to maintain high precision and efficiency. Outsourced sewing often leverages the latest industrial equipment without upfront capital costs, allowing businesses to access cutting-edge technology through partnerships. Investing in proprietary technology in-house enables greater control over quality and customization but demands continuous updates and maintenance expenses.

Risk Management in Sewing Production

In-house sewing offers greater control over production quality and timelines, reducing risks associated with delays and defects. Outsourced sewing introduces variables such as communication barriers and inconsistent standards, increasing the risk of errors and rework. Effective risk management in sewing production requires balancing cost efficiencies with stringent quality assurance protocols to mitigate supply chain disruptions.

Choosing the Right Sewing Solution for Your Business

Choosing the right sewing solution for your business depends on factors such as production volume, cost control, and quality standards. In-house sewing offers greater oversight, faster turnaround, and customization flexibility, ideal for brands with unique designs or quick market demands. Outsourced sewing can reduce labor costs and scale production efficiently, making it suitable for businesses focusing on high-volume orders and cost optimization.

In-house Sewing vs Outsourced Sewing Infographic

bizdif.com

bizdif.com