When managing sewing pet products, minimizing MOQ (Minimum Order Quantity) helps reduce initial inventory costs, while optimizing EOQ (Economic Order Quantity) balances ordering frequency and holding expenses to maintain steady supply. Choosing the right MOQ ensures timely production without excessive surplus, whereas calculating EOQ prevents stockouts and minimizes total inventory costs. Aligning MOQ with EOQ strategies enhances efficiency and profitability in the sewing pet industry.

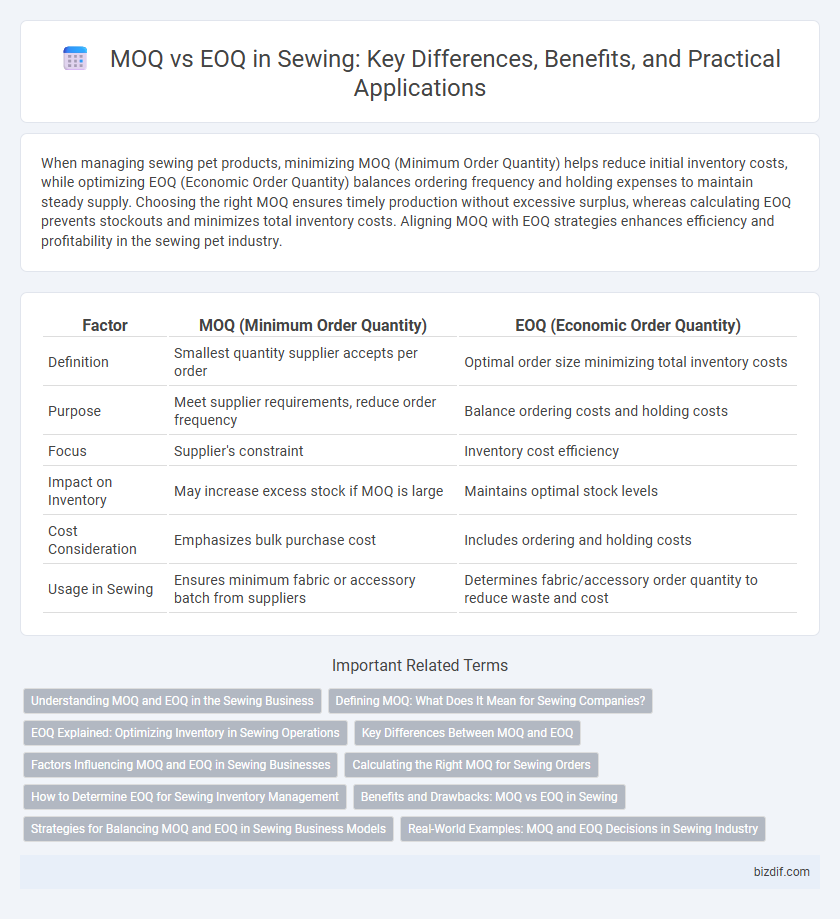

Table of Comparison

| Factor | MOQ (Minimum Order Quantity) | EOQ (Economic Order Quantity) |

|---|---|---|

| Definition | Smallest quantity supplier accepts per order | Optimal order size minimizing total inventory costs |

| Purpose | Meet supplier requirements, reduce order frequency | Balance ordering costs and holding costs |

| Focus | Supplier's constraint | Inventory cost efficiency |

| Impact on Inventory | May increase excess stock if MOQ is large | Maintains optimal stock levels |

| Cost Consideration | Emphasizes bulk purchase cost | Includes ordering and holding costs |

| Usage in Sewing | Ensures minimum fabric or accessory batch from suppliers | Determines fabric/accessory order quantity to reduce waste and cost |

Understanding MOQ and EOQ in the Sewing Business

Understanding Minimum Order Quantity (MOQ) and Economic Order Quantity (EOQ) is crucial in the sewing business to balance production efficiency and inventory costs. MOQ refers to the smallest amount of fabric or materials that suppliers require, impacting bulk purchasing decisions, while EOQ calculates the optimal order size to minimize total inventory costs, including holding and ordering expenses. Properly managing MOQ and EOQ helps sewing businesses reduce waste, maintain smooth production schedules, and improve profitability.

Defining MOQ: What Does It Mean for Sewing Companies?

Minimum Order Quantity (MOQ) defines the smallest number of units a sewing company must produce or order to justify cost efficiency and maintain profitability. This threshold ensures economies of scale in fabric purchasing, labor allocation, and machine operation, reducing per-unit costs in mass production. Understanding MOQ helps sewing firms balance inventory management and customer demand to optimize supply chain efficiency.

EOQ Explained: Optimizing Inventory in Sewing Operations

Economic Order Quantity (EOQ) in sewing operations calculates the optimal order size to minimize total inventory costs, including ordering and holding expenses. By balancing production schedules and material usage, EOQ ensures a steady supply of fabrics and threads without overstocking or stockouts. Implementing EOQ improves cash flow management and reduces waste in garment manufacturing processes.

Key Differences Between MOQ and EOQ

MOQ (Minimum Order Quantity) refers to the smallest number of units a supplier is willing to sell, ensuring cost-effectiveness in production and reducing per-unit costs. EOQ (Economic Order Quantity) calculates the optimal order size to minimize total inventory costs, balancing ordering and holding expenses for sewing materials. Key differences include MOQ being supplier-driven and focused on meeting production efficiency thresholds, while EOQ is buyer-driven, aiming to optimize inventory management and reduce overall costs.

Factors Influencing MOQ and EOQ in Sewing Businesses

In sewing businesses, MOQ (Minimum Order Quantity) is influenced by fabric supplier constraints, production setup costs, and storage capacity, as these elements dictate the smallest batch that can be economically produced. EOQ (Economic Order Quantity) depends on factors like inventory holding costs, demand variability, and lead times, optimizing order size to minimize total costs. Balancing MOQ and EOQ helps sewing businesses manage cash flow, reduce waste, and meet production schedules efficiently.

Calculating the Right MOQ for Sewing Orders

Calculating the right Minimum Order Quantity (MOQ) for sewing orders involves analyzing the Economic Order Quantity (EOQ) to balance production costs and inventory holding expenses. Accurately determining MOQ ensures efficient resource utilization, reducing material wastage and minimizing storage costs while meeting demand fluctuations. Integrating precise EOQ models with real-time sales data optimizes order sizes, enhancing profitability in fabric sourcing and labor allocation.

How to Determine EOQ for Sewing Inventory Management

Determining the Economic Order Quantity (EOQ) for sewing inventory management involves analyzing demand rates, ordering costs, and holding costs specific to sewing materials and finished products. By calculating EOQ, sewing businesses can minimize total inventory costs and avoid overstocking or stockouts, ensuring optimal fabric, thread, and accessory levels. Accurate EOQ models incorporate production lead times and seasonal fluctuations in garment orders to maintain efficient inventory turnover.

Benefits and Drawbacks: MOQ vs EOQ in Sewing

Minimum Order Quantity (MOQ) in sewing ensures bulk purchasing, reducing unit costs and streamlining production runs but can lead to excessive inventory and cash flow strain if demand fluctuates. Economic Order Quantity (EOQ) optimizes order size by balancing ordering and holding costs, minimizing waste and storage needs, yet may require more frequent orders that increase administrative workload. Choosing between MOQ and EOQ impacts inventory management efficiency, cost control, and responsiveness to market changes in sewing operations.

Strategies for Balancing MOQ and EOQ in Sewing Business Models

Balancing Minimum Order Quantity (MOQ) and Economic Order Quantity (EOQ) is essential for optimizing inventory costs and production efficiency in sewing business models. Implementing just-in-time inventory systems reduces excess stock tied to high MOQs while aligning EOQ with production cycles minimizes holding costs and stockouts. Data-driven demand forecasting refines order sizes, enabling manufacturers to negotiate flexible MOQs with suppliers without compromising on bulk purchase discounts or operational continuity.

Real-World Examples: MOQ and EOQ Decisions in Sewing Industry

In the sewing industry, Minimum Order Quantity (MOQ) ensures cost efficiency by requiring manufacturers to produce a set number of garments, often dictated by fabric roll sizes or machine setup costs. Economic Order Quantity (EOQ) balances inventory holding costs and order processing expenses, helping garment producers avoid excess stock or production delays. For example, a factory might set an MOQ of 500 units per style to optimize fabric usage while calculating EOQ to order materials every 1,000 units to minimize storage costs and maintain production flow.

MOQ vs EOQ Infographic

bizdif.com

bizdif.com