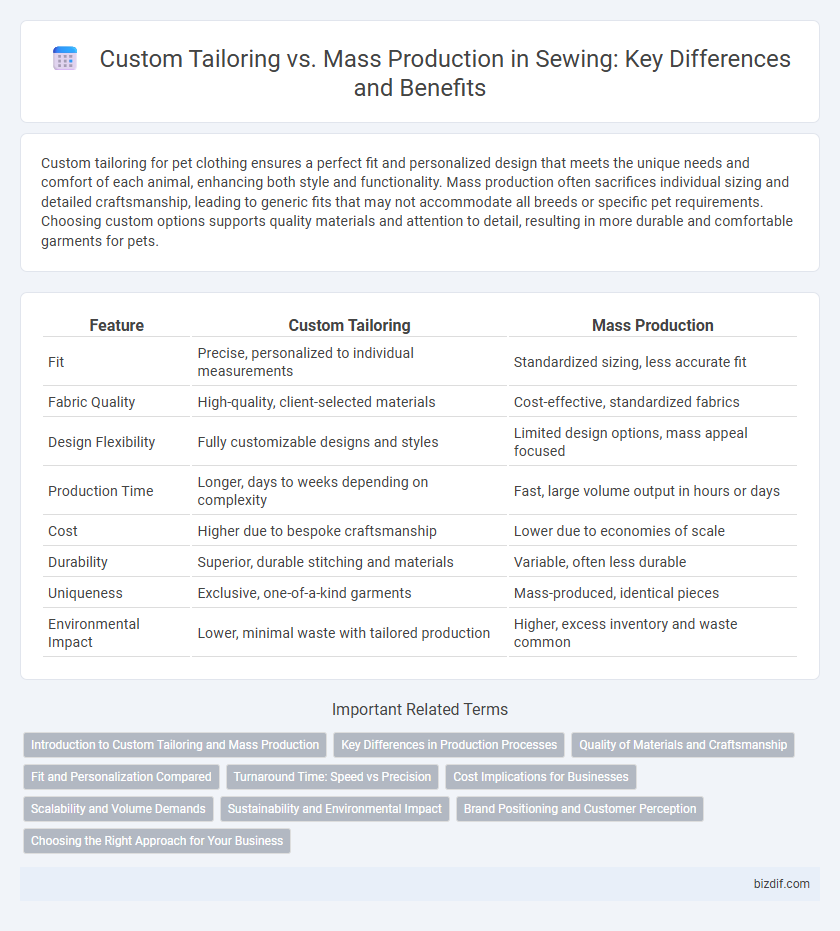

Custom tailoring for pet clothing ensures a perfect fit and personalized design that meets the unique needs and comfort of each animal, enhancing both style and functionality. Mass production often sacrifices individual sizing and detailed craftsmanship, leading to generic fits that may not accommodate all breeds or specific pet requirements. Choosing custom options supports quality materials and attention to detail, resulting in more durable and comfortable garments for pets.

Table of Comparison

| Feature | Custom Tailoring | Mass Production |

|---|---|---|

| Fit | Precise, personalized to individual measurements | Standardized sizing, less accurate fit |

| Fabric Quality | High-quality, client-selected materials | Cost-effective, standardized fabrics |

| Design Flexibility | Fully customizable designs and styles | Limited design options, mass appeal focused |

| Production Time | Longer, days to weeks depending on complexity | Fast, large volume output in hours or days |

| Cost | Higher due to bespoke craftsmanship | Lower due to economies of scale |

| Durability | Superior, durable stitching and materials | Variable, often less durable |

| Uniqueness | Exclusive, one-of-a-kind garments | Mass-produced, identical pieces |

| Environmental Impact | Lower, minimal waste with tailored production | Higher, excess inventory and waste common |

Introduction to Custom Tailoring and Mass Production

Custom tailoring offers personalized garment construction, ensuring precise fits and unique design preferences tailored to individual measurements and style choices. Mass production relies on standardized sizing and assembly-line techniques to produce large quantities of clothing efficiently and cost-effectively, often sacrificing customization and fit. The choice between custom tailoring and mass production impacts garment quality, fit accuracy, and consumer satisfaction based on specific needs and volume requirements.

Key Differences in Production Processes

Custom tailoring involves individualized measurement, handcrafting, and personalized fittings, ensuring garments are uniquely designed for the wearer's specific body shape and preferences. Mass production relies on standardized patterns, automated machinery, and assembly line techniques to produce large quantities of identical clothing efficiently. The emphasis in custom tailoring is quality and precision, while mass production prioritizes speed and cost-effectiveness.

Quality of Materials and Craftsmanship

Custom tailoring ensures superior quality of materials, as fabrics and trims are carefully selected to meet specific customer preferences, resulting in a personalized fit and durability. The craftsmanship in custom tailoring involves meticulous hand-stitching and attention to detail, enhancing garment longevity and aesthetic appeal beyond standard factory output. Mass production relies on standardized fabrics and automated processes, which often compromise material quality and artisanal precision, leading to faster wear and less individualized garment construction.

Fit and Personalization Compared

Custom tailoring ensures a perfect fit by using precise measurements and adjustments specific to the individual's body shape, resulting in enhanced comfort and style. Mass production relies on standardized sizes, often leading to compromises in fit and less personalized details. Personalized garments from custom tailoring allow for unique fabric choices, design elements, and alterations that reflect personal taste, which mass-produced clothing cannot match.

Turnaround Time: Speed vs Precision

Custom tailoring offers precise, personalized garment construction tailored to individual measurements, though it typically requires longer turnaround times due to meticulous craftsmanship. Mass production excels in speed by creating large quantities of standardized clothing rapidly, prioritizing efficiency over precision. This contrast highlights how custom tailoring values accuracy and fit, while mass production emphasizes quick delivery and scalability.

Cost Implications for Businesses

Custom tailoring demands higher labor costs and time investment compared to mass production, impacting overall expense structure for businesses. Mass production benefits from economies of scale, significantly reducing per-unit costs through standardized processes and bulk material purchasing. The higher initial expense of custom tailoring can be offset by premium pricing strategies, while mass production suits businesses targeting volume sales with lower profit margins.

Scalability and Volume Demands

Custom tailoring excels in delivering personalized fits but struggles to scale efficiently due to its labor-intensive processes and limited production speed. Mass production leverages automated machinery and standardized patterns to meet high volume demands consistently and cost-effectively. The scalability of mass production suits large retail markets, while custom tailoring remains ideal for niche, individual-specific orders.

Sustainability and Environmental Impact

Custom tailoring minimizes fabric waste and reduces carbon emissions by producing garments on demand, unlike mass production that often leads to overproduction and excess inventory ending up in landfills. Using high-quality, durable materials in bespoke tailoring extends garment lifespan, promoting a sustainable wardrobe. Mass production frequently relies on synthetic fibers and energy-intensive processes, significantly contributing to environmental degradation.

Brand Positioning and Customer Perception

Custom tailoring enhances brand positioning through exclusivity and personalized fit, appealing to customers seeking uniqueness and premium quality. Mass production emphasizes affordability and consistency, targeting a broader market with standardized sizing and quicker turnaround. Customer perception favors custom tailoring for craftsmanship and tailored experience, while mass production is valued for accessibility and cost-effectiveness.

Choosing the Right Approach for Your Business

Custom tailoring offers personalized fits and unique designs, catering to niche markets willing to pay premium prices, while mass production focuses on high-volume output with standardized sizing to reduce costs and increase accessibility. Selecting the right approach depends on target customer demographics, budget constraints, and brand positioning, with bespoke services excelling in luxury fashion and mass production thriving in fast fashion sectors. Integrating digital tools like 3D body scanning can enhance both methods by improving accuracy and reducing turnaround times.

Custom tailoring vs Mass production Infographic

bizdif.com

bizdif.com